High pressure hoses are used in pneumatic and hydraulic constructions. In the automotive industry, they are widely used in steering. Thanks to the built-in power steering, the driver has the opportunity not to put a significant load on the steering wheel when turning.

However, under certain conditions of use, various deformations of the tubes or hoses are possible. Subsequently, this leads to unstable operation of the unit, which can be fixed by repairing high-pressure hose hoses with their own hands or with the help of service station specialists.

Content

- 1 Hydraulics operation

- 2 Design features of power steering hoses

- 3 Alleged Damage

- 4 Carrying out repairs

- 5 Power steering troubleshooting

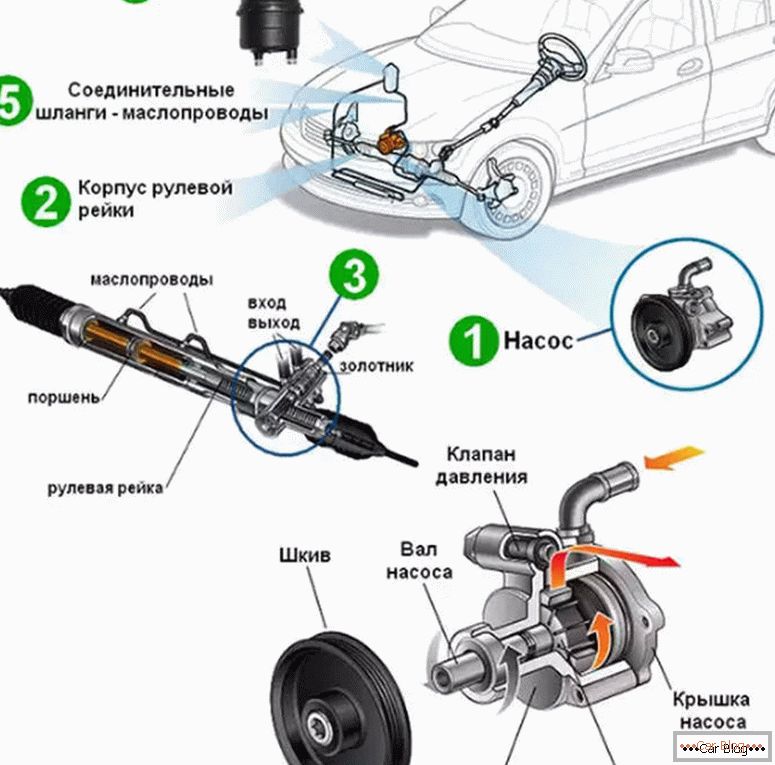

Hydraulic work

Hoses, which are commonly called high-pressure hoses, are flexible pipes, for which the main task is to pump working fluids. Specially prepared motor oils or working fluids based on mineral oils, aqueous solutions of emulsols, glycol, and grease lubricants act as the transported material.

Without high-quality flexible hoses that withstand the required pressure, and an extensive pipeline system, it is difficult to imagine the work of the hydraulic booster. In addition to the direct responsibility for pumping working fluid, such hoses act as dampers (compensators), increasing the operating period of connecting elements, fittings, fittings and the system as a whole.

Such results are facilitated by the absorption of vibration by flexible elements. The negative side of the phenomenon is that it requires periodic replacement or repair of power steering hoses in worn areas. After all all rubbing or kinking in a short time leads to the fact that the tube is leaking.

Design features of power steering hoses

In addition to working under high pressure, the hydraulic booster hose must have a reduced susceptibility to the working fluids used. Due to this, its inner surface is made on the basis of oil resistant and petrol resistant synthetic rubber.

The outer surface is protected by layers of wear-resistant rubber. Under certain circumstances, this layer plays the role of thermal protection. It may have such surfaces:

- corrugated;

- polymer;

- metal.

The outer and inner layer are divided by metal braid. This gives the entire structure the required operational strength and allowable stiffness. The wire layers alternate with rubberized elements.

It is customary to separate these types of hoses:

- Overhead. During the manufacture of this product, the turns of the wire are woven evenly around the entire perimeter.

- Braiding. Each turn covers the sleeve at a certain angle to the common axis so that the crossing with the turns of the previous layers takes place. This technology increases the strength of the structure and can operate under a higher pressure than the previous type.

The framework for the sleeves in some models is textiles. Geometric and physico-chemical parameters of wire and rubber are standardized for various applications.

Suspected damage

Motorists may encounter various types of hydraulic damage during operation, after which repair of power steering hoses is necessary. You can indicate the following items:

- Marriage manufacturer. The peculiarity is characteristic of insufficiently well-known manufacturers of hydraulic equipment. The failure is characterized by poor-quality crimping of the joint of the sleeve or fitting. This happens when the hardware is not debugged or misconfigured.

- Operational development. Damage is caused due to wear during operation of the mechanism. The main problems are cords, cuts and frayed areas. Often this occurs due to sagging of the hose due to incorrectly chosen length.

- Constructional inconsistencies. Failure occurs due to installation of equipment that is inappropriate according to the characteristics of the automaker. In such situations, it is possible to break the wire or break the fittings due to incompatibility of the pressure in the system with the allowable value for the hose.

- Temperature or chemical discrepancies. Damage to the structure can occur during operation at ambient temperature, on which such rubber was not calculated, as well as during the use of aggressive chemicals in the structure of the working fluid.

Damage to power steering hoses

All characteristics and permissible operational parameters for each hose are indicated by the manufacturer in the instructions for use.

Malfunctions of hydraulics with which further operation of the car is not recommended:

- fittings are significantly damaged by corrosion processes;

- significant break in the sleeves;

- significant abrasion of the outer part of the hose;

- the presence of complete or partial blockage inside the sleeves;

- lack of sealing compounds;

- disruption of the fitting with the bore diameter;

- fluid leakage at the joints;

- deformation or damage to the inner surface from high pressure or temperature rises.

In all cases replacement or repair of the sleeve is required

Repair

Based on the nature of the possible damage, it can be assumed that the most common repair of power steering hoses is to fix the fittings or to replace individual parts of the hose. Crimping sleeves will be required for replacement.

Self-repair devices

Algorithm works may be as follows:

- A broken sleeve must be disconnected from the system.

- A new hose will require the same length so as not to create excessive sagging. Measurement is carried out from nipple to nipple. In this case, we select a hose that satisfies all the geometrical data and pressure parameters. This will help marking indicated by the manufacturer outside. There will also be specified internal diameter.

- When repairing a high pressure hose, the ends are trimmed both outside and inside to the metal sheath. The procedure is faster using debarking machines.

- Fittings are selected according to geometrical parameters and technological thread data. Measurements are easy to carry out using calipers and thread gauges. Domestic and foreign fittings may differ among themselves by several criteria, so it is best to take measurements yourself.

- The fittings are crimped on the crimping equipment, using in each case suitable removable cams.

- The control probe determines the quality of work performed. At specialized factories, this operation is carried out with the help of special industrial stands.

For non-standard connections it is necessary to use repair kits with recommended fittings. You can unplug the head of the old fitting if it is not damaged, and solder it to the part to be pressed. This option is used in extreme cases, since the effect of this repair is short-lived.

Power steering troubleshooting

Damage to the hose in most cases occurs due to frequent rotation of the steering wheel with great effort. Wear occurs at the hose connected to the limiting valve.

When installing and repairing power steering hoses, it should be borne in mind that the allowable pressure in the system may vary depending on the car models in the range of 80 ... 130 kgf / cm2.

Such significant performance indicators do not allow the use of any types of clamps during repairs. It is necessary to choose the most acceptable option:

- Replacing the sleeve completely.

- Partial replacement of a deformed or worn area with installation of fittings on a new sleeve.

Replacing and installing the new hose is performed according to the following points:

- using a lift or jack, the front axle must be raised;

- the steering wheel turns out as much as possible to the left;

- a tube is placed on the end of the medical syringe for pumping residual working fluid from the reservoir;

- after pumping out the hose, it is necessary to disconnect and plug the hydraulic holes;

- a new sleeve is selected with operating permissible characteristics in order not to change the operational characteristics of the unit;

- In place of the old slag, a new one is mounted, after which the working fluid is poured into the system.

With proper performance of work hydraulics fully restored.