The number of cars that have a carburetor under the hood is reduced on the roads from year to year. Modern power plants are equipped with injection systems. To do this, their design uses nozzles.

С помощью них обеспечивается точное дозирование подающегося топлива, качественное распыление и устойчивая работа всей силовой установки. Когда бензин начинает «лить» через них, то повышается расход, снижаются экологические параметры. В этом случае нужно знать, how to check the nozzles without removing from the engine, чтобы выявить возможные неисправности системы.

Content

- 1 Design features

- 2 Indirect Symptoms

- 3 Fault Diagnosis

- 4 Diagnosis with electronic tester

- 5 Self cleaning

Design features

The principle of operation of the injectors is identical to the functioning of an electromechanical valve. When voltage is applied to the winding, an electromagnetic field is formed. Thanks to him, the core is attracted with a locking needle, and the directed flow of fuel enters the combustion chamber.

The nozzles are located in the final part of the fuel system and pass the liquid under high pressure. If the pressure begins to decrease, the outlet opening opens prematurely. This is a consequence of black smoke from the exhaust pipe. As the pressure increases, light smoke will form.

Indirect Symptoms

In most cases, when identifying the following problems with the fuel system, it is required to check the injector of the injection engine. Negative factors:

- there are dips or tugging of the car when the driver presses the accelerator pedal or switches the speed;

- starting characteristics at the start of the engine, which clearly become noticeable during the cold season, deteriorate;

- engine power drops, the dynamics of the car decreases;

- significantly increases fuel consumption;

- interruptions with work at idle.

If you have such doubts, you can turn to the station for computer diagnostics, but in some cases it helps to test the injectors with your own hands even in garage conditions.

Fault Diagnosis

The electronic control unit is engaged in the opening / closing of electromagnetic injectors. In older models of cars installed mechanical models that open by increasing the pressure in the system.

See also: Tuning carburetor SolexOne of the easiest ways to monitor their performance is to check for hearing. During operation of a faulty engine at idle speed, a slightly muffled sound should be heard at high frequencies. It can still be called deaf and ringing. This system requires mandatory cleaning in any convenient way.

It is necessary to check the integrity of the wiring that fits to the node under test. This is done visually or with a tester tuned to the definition of resistance.

To find out the problem details, the engine is started, the hood is opened, and then, in turn, they disconnect / connect the wiring to each injector. When the working injector leans back, this affects the engine in a certain way. A defective part when disconnected will have almost no effect on the current process.

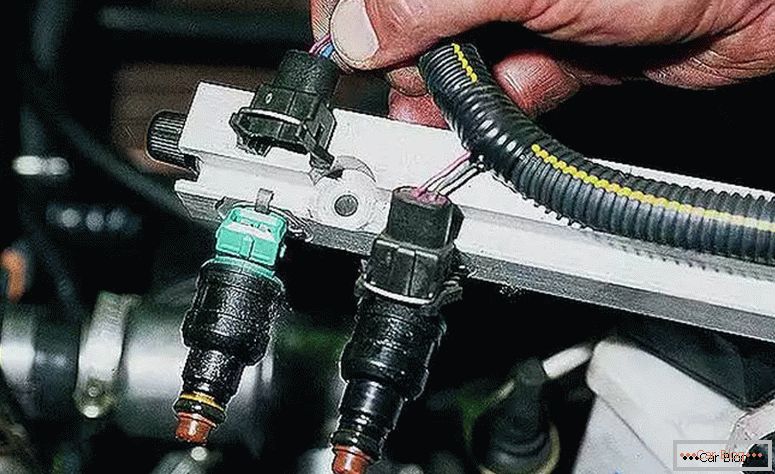

Check the nozzle at home will be after the removal of the fuel frame. After that, we connect the block of cables to the frame harness. Fuel pipes must be connected to each other, and with a wrench tighten the fittings.

The measuring capacity is set under each of the injectors, and the assistant starts the engine for 10 ... 15 seconds with a starter. From the engine we monitor the operation of each nozzle. The output of the fuel must be uniform in each case, and the volume of liquid in all cases must also be equal.

If more flow is detected through one of the channels, we carry out its immediate cleaning.

After the ignition is turned off, the hole must be tightly closed, in this case no leakage is allowed. Otherwise, the leakage also speaks of problems with the electrical circuit.

Diagnosis with electronic tester

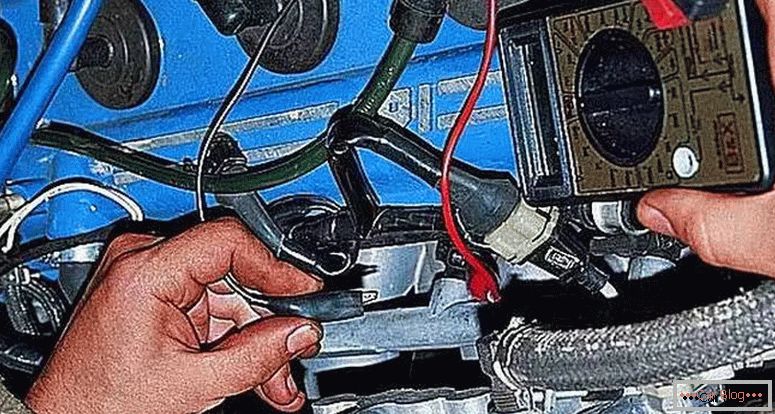

An effective method is to monitor the state of the system with a multimeter. For testing, you do not need to dismantle anything.

Pre-appeal to the technical literature on this brand of car to find out the reference value of resistance. Low or high resistance designs may be used.

See also: How to clean the injector with your own hands

We fold the negative contact from the battery, and disconnect the plug from the injector being tested. In this case, will help a flat thin screwdriver with which you can unlock the locking lock.

Turn on the tester in ohmmeter mode and measure. The instrument readings should not exceed 11 ... 16 Ohms in the case of a high value. For low resistance, an interval of 2 ... 5 ohms is assumed.

With possible deviations of real parameters from the reference data, it is worth carrying out the replacement of parts.

Self cleaning

Pollution can occur for various reasons, including due to poor-quality fuel. There are several ways to bring the injectors into working condition:

- mechanically;

- using ultrasound;

- by chemical means.

The most affordable of them for garage use is the use of chemicals. Additives poured into the fuel tank in certain proportions specified by the manufacturer of "chemistry".

During operation, it is necessary to accelerate the car on level ground to 110 ... 130 km / h and drive 10 ... 20 km. This will ensure the channels are self-cleaning to some extent.

In the conditions of a professional station, ultrasonic methods are used. They are recommended to be carried out at least after 30 ... 40 thousand kilometers or when identifying problems with fuel equipment.