If in a few words to describe the principle of operation of a diesel engine, then we can say that it depends largely on the pressure generated in the combustion chamber. There are not very many differences from gasoline engines: there is a unit, cylinder head, and injectors, which are somewhat similar to those used in the injection system of the injection. The only significant difference is that the fuel-air mixture is ignited not by the spark that slips between the electrodes of the candle, but by the enormous compression of air that heats and ignites the diesel fuel. Since the cylinders have a very high pressure, the valves must withstand heavy loads. Diesel engines are used for the most part on trucks, but it is also quite often possible to meet cars that run on diesel fuel.

Content

- 1 How the engine works on diesel fuel

- 2 What types of diesel engines exist

- 3 Main components of the fuel system

- 3.1 High pressure fuel pump

- 3.2 Fuel filter

- 3.3 Fuel injectors

- 4 Preheating and Turbine

- 5 Instead of conclusion

How does the engine work on diesel fuel

Fuel ignition in a diesel engine

The diesel engine is based on compression ignition of the fuel. Moreover, diesel fuel, falling into the combustion chamber, is connected to the heated air. This is the difference in the formation of a mixture from a gasoline engine - diesel fuel and air enter the combustion chambers independently, are mixed immediately before ignition. First comes some air. When it shrinks, its heating begins (approximately to 800 degrees). Fuel enters the cylinder under pressure from 10 to 30 MPa. After that, it ignites. When working there is a lot of noise, and the level of vibration is quite high. On such a simple basis, it is easiest to distinguish a car with a diesel engine. By the way, there are still candles in his design, only the purpose of them is completely different. They do not ignite the mixture, but they warm up the combustion chambers to make it easier for the engine to start in the winter. They are called - glow plugs.

There are both two-and four-stroke diesel engines. The latter are used on most vehicles and operate in this mode:

- Intake stroke

- Air is compressed and fuel is injected.

- The explosion of the combustible mixture, the piston moves down, making a working stroke.

- Produced exhaust gases, the beginning of the first stroke.

Spark plugs diesel engine

До некоторых пор дизтопливо имело низкую стоимость, поэтому экономия для владельцев дизельных машин была существенная. Но вот капитальный ремонт, например, обходится намного дороже, в отличие от бензинового мотора. Да и diesel engine device для большей части автомобилистов малознакомо.

What types of diesel engines exist

If we carry out the separation by design, then we can distinguish only three types:

- Engines with split combustion chamber. The essence is simple - the fuel-air mixture does not immediately enter the combustion chamber. Initially, it falls into a separate compartment, called the vortex chamber. This camera is located in the cylinder head. Between the combustion chamber and this compartment is a small channel. It is in the vortex chamber that the air is able to compress to high pressure. Consequently, its heating will be stronger and the ignition of the fuel improves. The initial ignition of the fuel takes place in the same compartment. Then the process smoothly passes into the main combustion chamber.

- With a combustion chamber not divided into compartments. Such motors have a maximum noise level, but they consume less fuel. In the piston there are small depressions into which the fuel mixture falls. It ignites directly above the piston, after which the force of the explosion pushes it down.

- Pre-chamber internal combustion engines have in their design plug-in prechamber. From it to the main combustion chamber is several thin channels. Most of the characteristics of this type of diesel engine (noise level, resource, toxicity, fuel consumption, vibrations generated, power) depend on the number of channels, their thickness and shape.

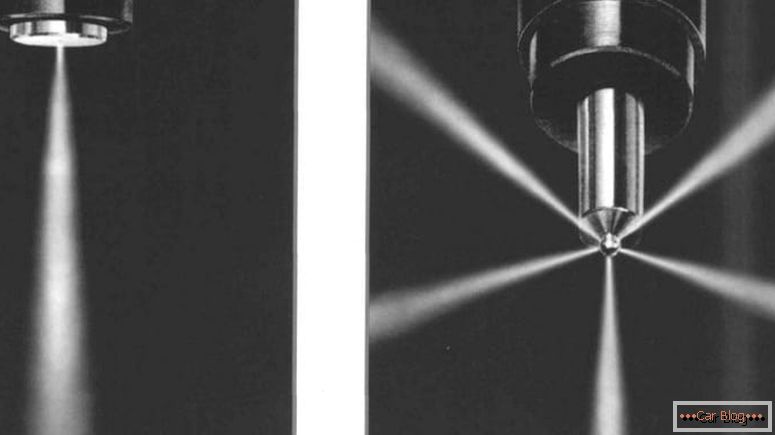

Diesel engine injectors

The main components of the fuel system

It can be said that the fuel system is the basis of a diesel engine. It delivers fuel to the combustion chamber under a predetermined pressure. And you need a strictly defined amount of diesel and air. The main elements of the system:

- Fuel pump (high pressure fuel pump).

- Fuel filter.

- Nozzles

Рассмотрим the device of the fuel system of a diesel engine более подробно.

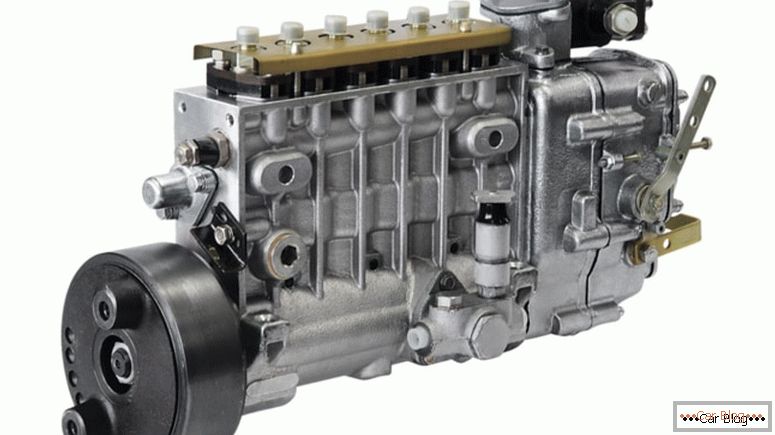

High pressure fuel pump

On cars that today can be found on the roads, mainly installed pumps of the following types:

- Distributive.

- Plunger (row).

The function of the pump is to pick up fuel from the tank and transfer it to the injectors. Moreover, its work depends on many parameters, including the air pressure in the turbine, the number of revolutions of the crankshaft and others. The main difference from pumps installed on simple gasoline cars is that the diesel engine pump needs to create a much higher fuel pressure so that it can still be injected directly into the combustion chamber, which already has high pressure air.

High pressure fuel pump дизельного двигателя

Fuel filter

For each motor has its own, irreplaceable type of filter. As the name implies, it is necessary for cleaning diesel fuel coming from the tank. They will be detained any, even the smallest, particles. It also removes excess air and moisture from the system.

Fuel injectors

The high pressure pump has a strong connection to the injectors. It is from these two elements that it depends on whether the fuel enters the combustion chamber in a timely manner (and it must be sprayed at the moment the piston is at the top dead center). The following types of injectors are used in the construction of a modern diesel engine:

- Multi-holed.

- Having a font distributor.

The injector distributor is responsible for the shape of the flare so that the fuel evenly enters the combustion chamber and its ignition occurs most efficiently.

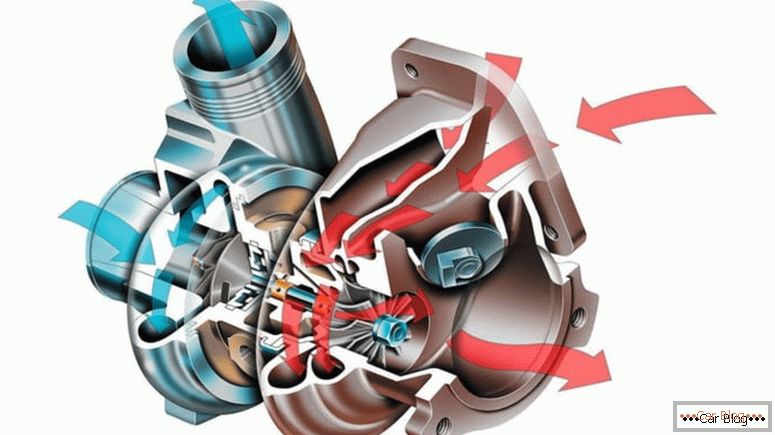

Preheating and Turbine

Diesel turbine

The cold start system is necessary for warming up immediately before starting the engine. As already mentioned, in the combustion chamber there are candles that work like a soldering iron - they have a spiral, under the action of electric current it heats up to nine hundred degrees. All air entering the combustion chamber is also heated. Such a system is triggered immediately before the start of the start and turns off a quarter of a minute after the engine starts. In the process of work she does not participate. Thanks to this system, it is easier to start the engine in extreme cold (unless the diesel in the tank and the fuel line gets a jelly-like appearance).

See also: How to choose engine oil by car brandBut the turbocharging system can significantly increase the power produced by the engine. Due to it, a large amount of air is injected. As a result, the combustion process is greatly improved. In order for air to flow under pressure in any operating mode, a special turbocharger is installed. Let us consider in general the device of the turbine of a diesel engine. Turbine - consists of two impellers, located on a shaft of steel. Moreover, one of the impellers is located in the exhaust manifold and is unwound with exhaust gases. In this case, the shaft begins to transmit rotational motion of the second impeller, which is already in the intake manifold. With its help, additional air pressure is created in the intake tract. The turbocharging system is enclosed in a cast iron housing. Like all engine parts, the body is subject to wear. Impeller speed is very high, it is for this reason that destruction occurs. The turbine casing has the shape of a cochlea; therefore, a complex movement of the gas flow takes place in it, setting in motion the entire pressurization mechanism. In the manufacture of the turbine is extremely important precision casting and fitting of all parts.

Instead of conclusion

Споры о недостатках и преимуществах дизельных двигателей звучат с момента их появления. Нельзя однозначно сказать, что именно дизельный мотор является правильным выбором. Выбрать или нет автомобиль с дизельным мотором — решение по-прежнему каждый принимает сам. Поэтому необходимо знать, how does a diesel engine work при различных нагрузках и в определенном климате.