At first glance, minor components in the car can significantly affect the performance of entire systems. An example of such work is the alternator belt tensioner. Thanks to him, the force is corrected during the transmission of rotation.

In the process of engine operation, it rotates all the time. There is a deterioration of the working parts of the node, working under a certain force. For high-quality work, the alternator belt tensioner roller is periodically required to be replaced.

Content

- 1 Performance properties

- 2 Node diagnostics

- 3 Visual fault check

- 4 Repair work

Performance properties

The operation of the generator and consumers, which it feeds with electricity is impossible without high-quality work of the tension knot. All automotive manufacturers strive to make this unit more advanced than those of competitors, while the basic principle of operation remains unchanged.

In the configuration of the classic site are usually found such elements:

- work roller equipped with built-in rolling bearings;

- figured bracket, fixed next to the generator with several bolts;

- bolt for fixing the roller in the desired position.

A similar roller is used for tensioning the timing belt.

You can also find some modifications of the work item:

- in the construction of the roller is used eccentricity, the rotation of which can provide the necessary tension of the whole structure;

- the fixation of the roller is provided on a movable bracket, where a special bolt is used as a tensioner.

For each of the design decisions, the maximum force from the belt tension is transmitted to the bearing. It takes radial loads, due to which rapid wear of elements occurs.

Node diagnostics

The driver must be aware that there are direct and indirect signs indicating a malfunction:

- there is no indication of battery charging on the dashboard;

- when the engine is turned on, the alternator belt tensioner pulley is heard, which is felt even without opening the hood;

- the characteristic sound is also a metal hum from a worn bearing;

- there is a noticeable vibration of the tensioning roller or working belt, which is characterized by the wear of the sleeve, which must be done immediately;

- the deflection measured on the belt significantly exceeds the allowable 1.5 cm;

- the presence of free running on the roller or on the tension pulley refers to signs of wear of the bearing;

- one of the sides of the belt is noticeably worked out or stretched, which indicates misalignment or deflection in the bracket design.

You also need to protect the area from possible contact with the belt of oil or other fluid that promotes slipping on all surfaces.

Visual fault check

Before changing the alternator belt tensioner pulley, it is necessary to identify the reason or several reasons for which there was a malfunction. For this, the following activities are carried out:

- the operating conditions of operation of the entire chain involved in the operation of the generator are assessed;

- the root cause of the node failure is determined;

- current wear of structural elements is controlled;

- a visual inspection of the traces of the belt on the tension and guide rollers is carried out, the presence of which indicates that the development of the bearing was to blame;

- check for unacceptable contamination of surfaces, if necessary, carry out mandatory cleaning.

In some cases, replacing either the roller or the belt does not give the desired result. The reason may be in contact with antifreeze or oil on the belt.

Repair work

When the car owner found a malfunction in the mechanism, it is necessary to begin to eliminate them. Before dismantling it is also worth taking care of the availability of a repair kit for the unit.

After carrying out diagnostics and obtaining unsatisfactory results for the bearing, we are preparing its mandatory replacement. We eject the developed element, since it is not subject to resuscitation.

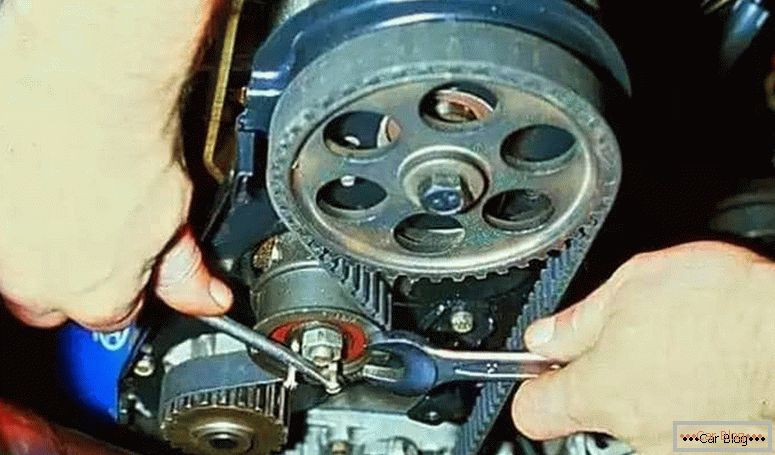

Perform the following sequence of actions:

- we throw away contacts from the battery, de-energize the car;

- fix the crankshaft in one position with the help of special devices or car mount;

- remove stress from the node by loosening the tensioning bolt;

- remove the tension roller and belt, as well as with structural need get rid of the bracket;

- unpack the repair kit with new parts and install them on the prepared place in the reverse order of disassembly.

It is necessary to provide sufficient force on the fit, otherwise there will be such results:

- weak tension will not transfer rotation to the generator, and accordingly will not provide the car with the required electrical load;

- strong tension will lead to rapid wear of all work items, including the bearing, belt, pulleys, roller, etc.

The optimum force is controlled by electronic measuring devices. Experienced car owners check this effort with their hands. With manual control, the belt tape must, without significant effort, rotate a quarter of a turn around its axis.

There are models of cars, equipped instead of several drive belts with one, ensuring the operation of the generator, air conditioning, hydraulic booster and other devices. For full-fledged work in such systems automatic tensioners are used.

The node increases the load and responsibility for the full operation of several systems. As an "automatics", you can see the installed spring, which provides the required force on the belt. When restoring the performance of such units, there is a complete replacement of not only the belt, but also the entire automatic tensioner. The condition of the bearing in such a situation is not taken into account, since it does not change separately from other structural elements.