The smooth operation of a modern internal combustion engine is impossible without high-quality and stable sources of electricity. In the process of starting the motor, this role is performed by the battery, and after the engine starts, the function is assumed by the generator. Taking away some power from the power plant, the generator supplies all electrical consumers in the car with voltage. Additionally, the battery is recharged.

If, for some reason, the generator does not cope with its duties, then the main source of current remains the battery, and does its job until it is completely discharged. Staying with a discharged battery and an idle generator in the middle of the road is unlikely to please anyone, so let us tell you how to check the generator on a car without removing it from the mount.

Content

- 1 Indirect Problem Identification

- 2 Fast troubleshooting and repair

- 3 Testing with a multimeter

- 4 Checks for individual generator nodes

Indirect Problem Identification

The presence of problems with the generator can signal associated factors. Manufacturers install on the instrument panel control red light, notifying the driver of a weak battery or its absence.

Low brightness lighting both inside the cabin and in the exterior optics indicates an insufficient level of charge. Also, the increased load while simultaneously turning on several power consumers leads to a rapid discharge of the battery.

Requires constant battery charging

The motor receives a slight vibration and emits a slightly muffled continuous squeak from the side of the generator mounting. Often even visually noticeable belt slippage on the pulley.

It is necessary to test the generator for operability then, when the brightness of the optics becomes directly dependent on the speed power plant. This does not apply to a small change in illumination when prowazovka idling. However, if during the movement you add the number of revolutions and the light becomes more intense, and when reset, the brightness decreases, then this is evidence of problems with the generator.

Fast troubleshooting and repair

In order to check the voltage on the generator, it is not necessary to dismantle this electrical component from the seat. The operation can be done with a multimeter.

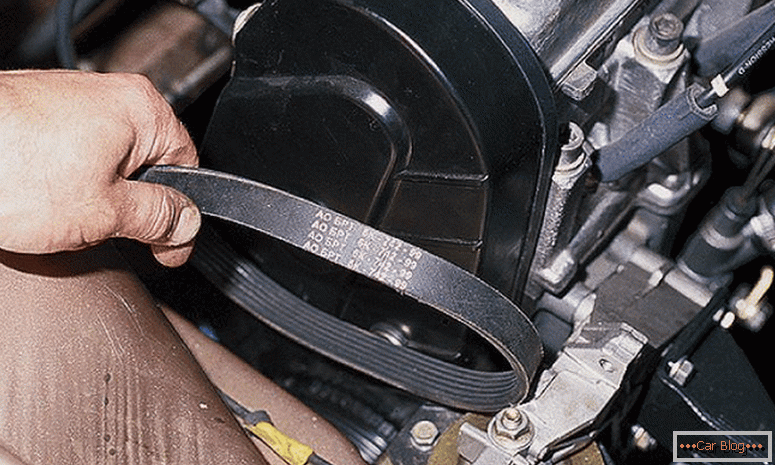

Replacing the belt on the alternator pulley

Also, most problems can be eliminated without significant labor or time costs.

- The main reason for the lack of battery charging is weak tension on the belt drive. The deflection of more than 10-15 mm when pressed in the middle must be eliminated. The torn belt must be changed, and the stretched one is often sufficiently tightened through the tensioner. If the effort is not enough and there is not enough thread for the tension, then the belt must also be replaced. The cost of the product is small.

- You need to make sure that nothing prevents the rotation of the rotor. The generator housing must be free of cracks and dents. The rotor must spin without effort or clips around the entire circumference.

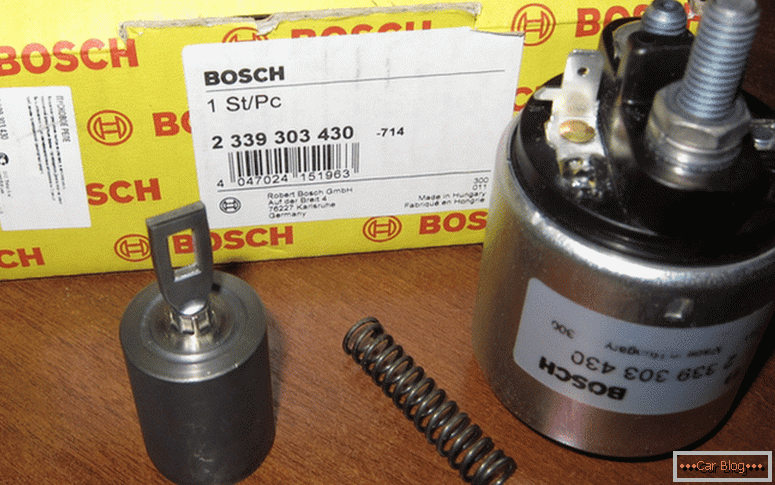

- The electrical part must also be in good condition. Fuse can be changed as a prevention. Charging relay must also be inspected and replaced if necessary.

You need to know that there are problems with the electrical system of the car are similar in symptoms, but they may have different reasons.

Multimeter Testing

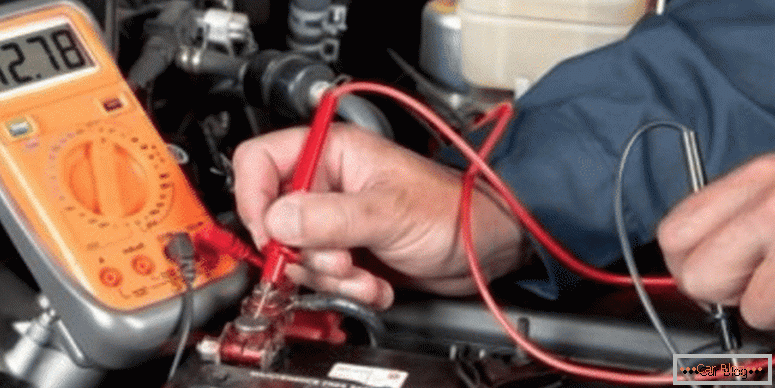

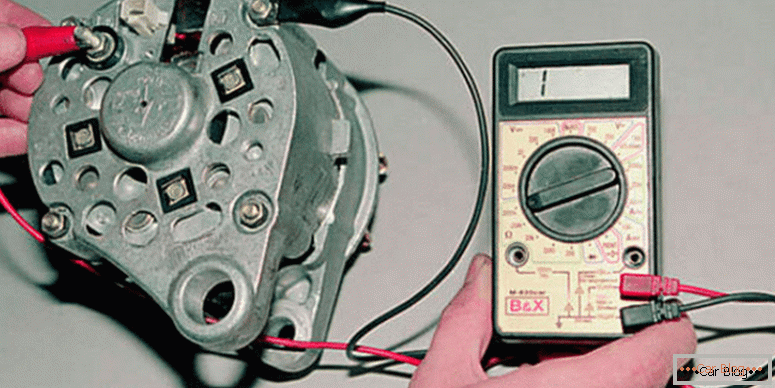

The test method using an electronic multimeter is the most popular. To do this, you must set the device in the resistance control mode (ohmmeter). First of all, it is customary to inspect the rotor on the dismantled generator, and then the stator. The last test diode bridge. Additionally, you can check the node with a voltage regulator or the quality of pairing brushes with the surface. Before checking the generator with a multimeter, you need to set the correct modes on the measuring device.

Test measurements by multimeter

When the brush assembly becomes clogged, the voltage supply may not beThere are also options with its unstable supply to consumers. Visual monitoring of performance can begin with the health of the brushes and how they come into contact with the rings.

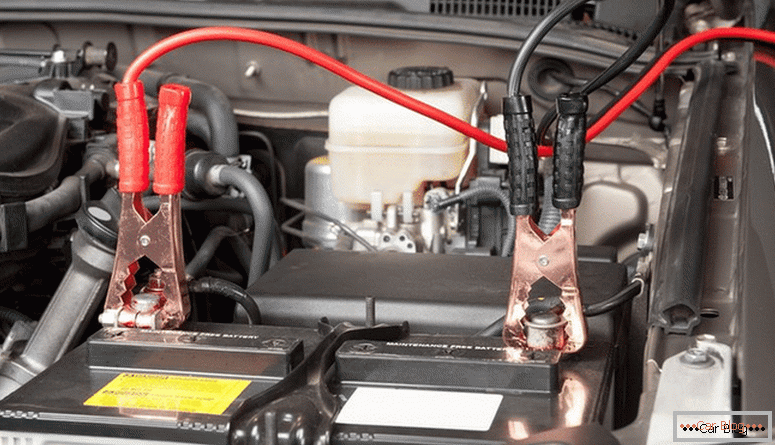

Voltage monitoring should start with checking the battery in the car. Admissible is considered to be the interval of 12.5-12.8 V for a fully charged device. Further measurements by a multimeter are made on the engine running.

After the start, a few minutes are given to warm up the motor, and then all electricity consumers start up, including the stove. Measurements at the battery terminals should be within 14-14.2 V. It is normal for short-term jumps up to 0.5 V. to be considered. If the difference is longer than 1V, the problem may be a generator failure. This method checks the relay.

Checks for individual generator nodes

To obtain more accurate results, you can check the nodes separately. This is done by a multimeter tuned to a voltmeter or ammeter mode.

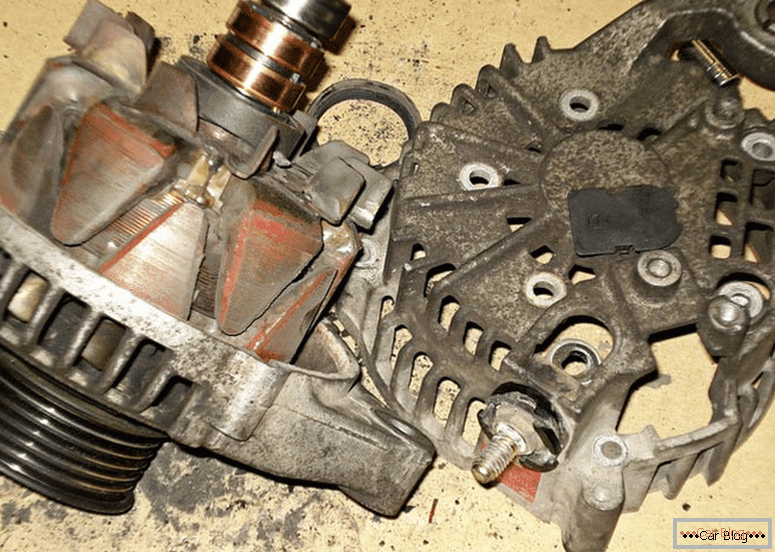

Check dismantled generator

It is strictly forbidden to check the operability of the generator windings using a short circuit, “to spark”!

When checking the diode bridge find out the suitability of each diode. To do this, the multimeter is set to the sound signal mode and the test is carried out separately for the diodes. Measurement is carried out on each element twice, swapping probes. Sound should only be in one direction. If the signal is audible during direct and reverse measurements, the diode is faulty.

See also: How to replace the electrolyte in a car batteryMeasurements are carried out with the stator. Identify need to breakdown wires to the housing. One multimeter probe is connected to the end of the winding, and the second is connected to the body, as a result there should be an infinite voltage value on the screen. If the readings are less than 50 kΩ, then this is evidence of a breakdown. Visual inspection should indicate no burns or other visible damage.

Disassembled generator

On the rotor, measurements are also made using a multimeter. The indicator is also monitored in the “resistance” mode (ohmmeter). Measurements should be carried out between the slip rings. The result should be several ohms. If the resistance tends to zero, this situation is a sign of damaged wiring.

Changing the winding on the rotor or stator at home is inefficient. It is necessary to replace the generator completely.