A modern car can no longer be imagined without electrical equipment. Advanced functionality (navigation, audio system, air conditioning, on-board computer, etc.) - an integral part of the transport, responsible for the comfort and convenience of its operation. However, the new additions put a strain on the power generation system. Electrical systems take charge from the battery and the generator. To actuate the generator and require a belt, the main task of which is to transfer torque from the crankshaft to the generator shaft with a gradual increase in rotational speed. This creates electrical energy, which the entire network of the car receives.

Content

- 1 What is an alternator belt?

- 2 Types of alternator belts

- 3 Major problems

- 4 In what situations does an unpleasant sound occur?

- 5 If you do not take into account the whistle, what it can turn around?

- 6 Generator Belt Diagnosis

- 7 Tension and everything connected with it

- 8 open belt alternator

- 9 Belt replacement process

What is an alternator belt?

The machine contains several belts in its system. Many often confuse the alternator belt with the timing belt, although its activity is associated with the camshaft. All belts work on the same general principle. The difference is only in the design of parts for different engine models. Externally, the alternator belt looks like a flexible tape in the shape of a circle. The most common material is rubber, containing inside a laminated basis of polymer filaments.

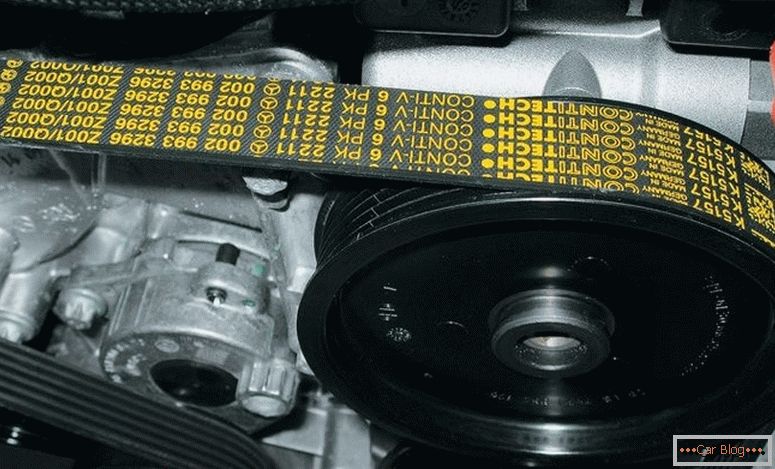

Generator belt

When choosing a product take into account the size, thickness and profile. Temperature influence, elasticity and contact with the pulleys must also be taken into account, otherwise the negligent attitude and the mistakes made will manifest themselves in a short time. Problems are accompanied by noise and unpleasant whistling. A natural question arises, why the alternator belt whistles at start? We will look at the answer to it further.

Types of alternator belts

There are three types:

- Gears. Provide accurate transmission of torque, because of this they are used in (timing). They have a wedge-shaped profile, on the inside they consist of gears and transverse gear channels. The presence of such teeth reduces the risk of slipping.

- Клиновые. On a cut have the form of a trapezoid. Reliable, as they can even with overload, transmit great effort. Only possible high slippage probability. Used to transfer torque from the crankshaft to several devices, but not suitable for reverse bending. Very often you can watch them on cars of the old type where the drive from the crankshaft pulley is made only to the generator.

Car Poly V-Belts

- Semi-wedge (multi). Wide and flexible. They are similar in appearance to several V-belts glued together. From the inside of the small sizes longitudinal grooves are located. High flexibility makes it possible to use products of this type not only for driving the generator, but also for other engine components (compressor, hydraulic booster, liquid pump).

Combines all types, only the dependence of quality on price. Making a choice, it is worthwhile to lean towards the brands of well-known manufacturers - this will at least delay the appearance of the whistle for a longer period.

Main problems

Since the drive belt is flexible, sooner or later it suffers change. It may be:

- heavy wear. Over time, the profile decreases, as it rubs against the pulleys while rotating. The brushed surface begins to slip, and the transmitted force is minimized, with the result that the generator does not receive the necessary energy;

- stratification. Usually the problem is observed on low-quality products. It all starts with damage to the pulleys. Violation of geometry leads to the fact that the belt is intensively deformed on the one hand, and the reinforced thread crawls out. After this, a discrepancy into component parts occurs;

Belt removal

- cliff. The phenomenon is quite rare, since breaking the reinforcing fibers is not easy. This happens in cases where one of the parts of the system is wedged. As an example, the destruction of the bearing of the generator. In this case, the rotor freezes and the belt breaks under considerable force;

- pulling. Strongly clamped belt, hardly overcomes the resistance of tension. Such defective, slow rotations and cause extraneous noise;

- subsidence. It can be observed when the product is stretched over time and the previous tension weakens. In addition, the subsidence may be caused by the penetration of fuel and lubricant mixtures on its surface. Poor-quality rubber is deformed and slippage occurs.

The main symptom of problems with the generator drive belt is creaking and whistling. In cars with the presence of a tensioning roller, in addition to the problems listed above, a whistle can also speak about the wear of the roller bearing itself.

In what situations does an unpleasant sound occur?

Very often the appearance of a squeak does not have a clear pattern and consistency. Do not immediately go to extremes and carry out the replacement. First it is worth finding out the reason.

Drive belt

The whistle of the generator belt is manifested during different modes of transport operation:

- on a cold engine when warming up. A short whistle, talks about the poor quality of the belt. At subzero temperatures, the product hardens and must be warmed up before work;

- after switching on several current consumers (lights, heating, audio system, air conditioning, etc.). There is a heavy load on the generator;

- constantly running engine;

- car operation in conditions of high humidity - when the alternator belt whistles in the rain or in wet weather.

In all cases, it is necessary to carry out a complete diagnosis of reclining inappropriate options.

If you do not take into account the whistle, what it can turn around?

Своевременно нерешенная проблема с ремнем генератора впоследствии может ударить по бюджету водителя. Первое, что может случиться – это хроническая недозарядка аккумуляторной батареи, которая приведет к полной утере заряда и выходу АКБ из строя. Второе — свист может говорить об износе ремня и его скором cliffе. И если подобное случится где-нибудь загородом — далеко вы на автомобиле не уедете.

Note: often on cars, the alternator belt also rotates the pump pulley of the cooling system, respectively, when the belt is broken, the engine will stop cooling and you cannot move on such a car. Otherwise, the inevitable overheating of the engine with sad consequences.

When the whistle was just beginning to be heard, it is best to immediately diagnose the condition of the belt and its tension.

Generator Belt Diagnosis

The check is reduced to the following actions:

- Inspection for integrity.

- Evaluation of the degree of tension.

- Inspection for cleanliness and dryness of the shaft.

- Check the line of two pulleys for offset.

In case of identifying the cause, it is necessary to replace the product. If the belt is just soiled, it must be cleaned and left in place. When there are no flaws, it is quite possible that it is just hard, in this case you can either replace it or carry out preventive actions, in the form of applying a special additive. Automotive chemicals makes the alternator belt much more elastic, eliminating friction and the occurrence of cracks.

Please note that the use of auto-chemistry will not relieve you completely from the problem, as this is a temporary measure, which should be used only if there is no possibility to replace the belt.

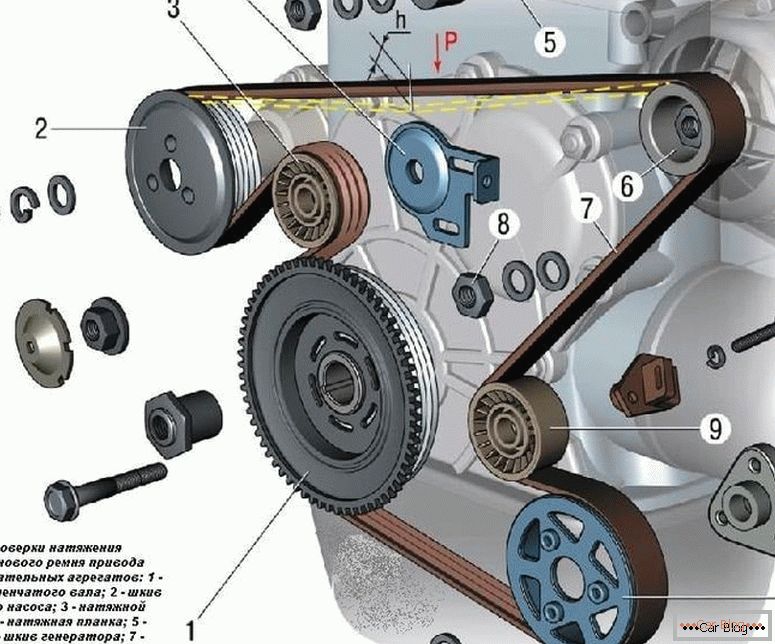

Tensioner belt alternator

Tension and everything connected with it

Suppose that during a visual inspection, you were able to eliminate the presence of various kinds of defects, and the question: how to eliminate the whistling of the generator belt, still worries. In this case, you need to estimate the tension. To find out the norm, you need to look at the car's data sheet. Poor tension lowers the efficiencies of the car generating device, as a result of which the current of the required force is not generated. Proper tension, on the contrary, has a beneficial effect on all work and service life: water pump, battery, belt itself and bearings. When the belt is tightened, the bearings are destroyed. Follow the manufacturer's instructions only.

As an example, consider the fact that the manufacturers of the domestic automobile industry, with an applied force of 10 / kg. Cm, set the deflection of the belt at 15 mm. If you have a domestic car brand, then the parameters can be checked like this: put a strip of metal 50 cm in the top of the crankshaft pulley and the desired force in the middle of the belt. After a ruler determine the deflection. According to the result, navigate with the actions. When the design is not a clamp, it is worth checking for wear roller. For owners of mechanics, it will be useful to view the pulleys and bearings for curvature relative to the axis of movement of the belt.

Belt Tension Checkout

To tighten the belt:

- Loosen the alternator mounting nut.

- Further the belt weakens.

- Use the pry bar as a lever. We move the generator towards the engine compartment.

- Expose the desired degree of tension.

- After fix the position of the generator, tightening the nut to its original position.

- We test system, we include any consumers of energy. If the suite is missing, then the work is done, right.

Open belt alternator

На ремнях даже хорошего качества и при нормальной нагрузке со временем появятся: потертости, трещины, стертые зубья и разрыв. Если беда в виде cliffа ремня генератора застигла вас в дороге, а запасного изделия нет, то возможно поправить ситуацию подручными средствами. Помните, что данные советы – это всего лишь временная мера, когда вы вдали от гаража. Отпускаем натяжитель до предела.

After as a replacement, use the following tools:

- tie;

- lap belt, connect the ends with wire straps;

- rope;

- nylon tights.

Deformed alternator belt

Keep in mind that the alternative should be no less strong than a damaged alternator belt. For greater strength, you can fold the replacement in half. After the substitute is installed, tension it and verify the design is working.

Belt replacement process

Consider a common, optimal replacement option. Required tools such as:

- The key is on the “19” (cap) and the deep head on the “17”.

- Ratchet handle.

Turn off the key nut securing the generator to the bracket. When the belt needs a little loosening, we move the generator. After install new. Weighting is adjustable tension. We expose all released nuts. We check the work by running the motor and additional consumers.