The responsible driver is obliged to monitor the state of the security systems in the car. Especially important is the presence of serviceable brakes, which will ensure the controllability of the vehicle.

An important role in the performance of the brake system is played by the state of the pads, their quality and the intensity of production. However, the quality of the brake disc also can not be neglected. Aggressive grooves on the surface do not contribute to effective braking. To remove them and restore the geometric parameters, the brake discs are applied without removing them by hand or with the help of special equipment.

Content

- 1 When the need for a groove

- 2 Methods of processing brake discs

- 3 What will be the result

- 4 Work

- 4.1 Use of machines

- 4.2 Work improvised means

- 5 Conclusion

When there is a need for a groove

With each car is the documentation from the manufacturer, where you can find recommendations for operation and repair. It also describes the technical and operational characteristics of different systems, including braking.

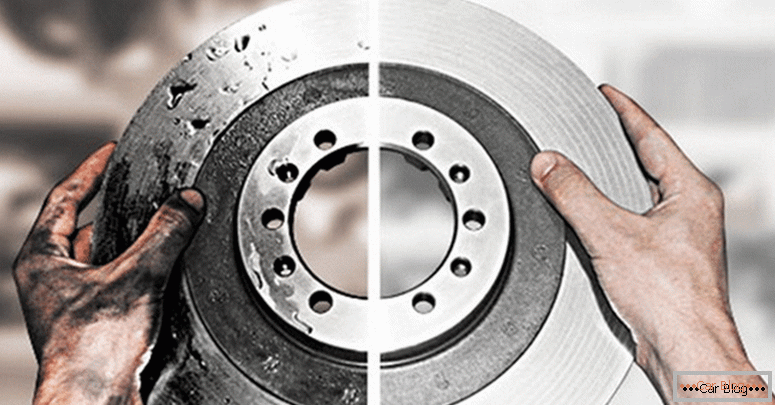

Before groove and after

The average indicator of modern cars is mileage up to 100 thousand km for brake discs and up to 30 thousand for pads. Fluctuation recommendations mileage vary depending on the brand of car, model or year of manufacture of the car.

Also on the intensity of wear has an impact individual driving style. Frequent braking or sudden braking at high speed gives a greater production of a disk / block pair.

Identify early wear of this site can be on several grounds:

- going intense disk heating, which can be seen after a relatively short mileage by touching any part of it;

- arise extraneous sounds (creak, whistle, etc.) after pressing the pedal;

- increased stopping distance, and decreased system performance;

- in the process of braking occurs steering wheel vibration, sometimes it is supplemented by a small kick in the pedal;

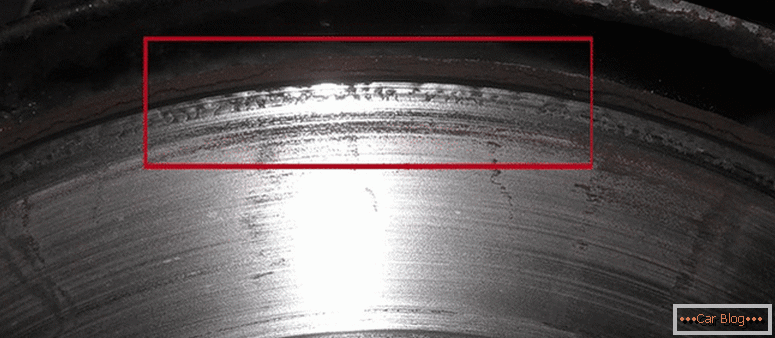

- inspection of the disc revealed a clear wear and corrosion elements with possible damage.

Any one of these reasons will be enough to look for a machine for driving brake discs without removal or removal. However, if this operation has already been carried out repeatedly with this car, then it is necessary to control the thickness of the discs in order not to regrow them. The minimum size is specified by automakers in the instruction manual for cars.

See also: How to repair block ABS with your own handsBrake disc processing methods

The most inconvenient machining option is the machining of the degraded surface on a lathe. To do this, you have to remove the wheel, disassemble the assembly and dismantle the part for processing. After the groove we return everything in place.

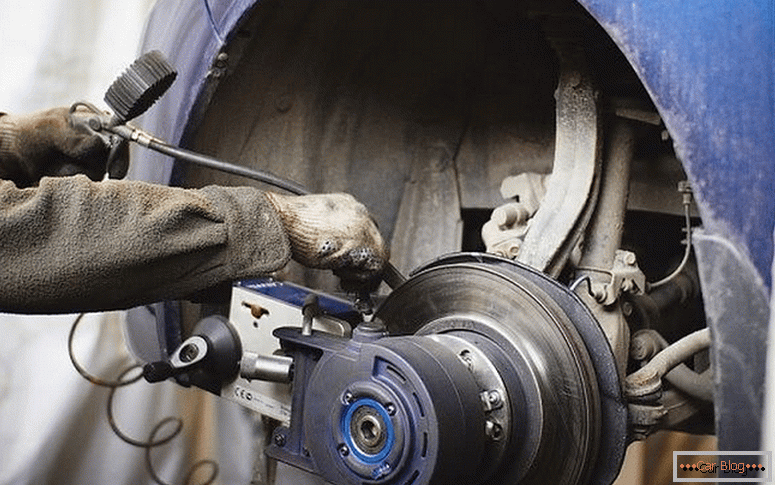

Modern sleds are able to perform the operation even without dismantling the disc. It is enough just to remove the wheel, and then fix the unit on the car. Processing takes several minutes. After it we return the wheel to its place and we can immediately go.

In the third case, it is enough to use a file or a grinding stone. No special equipment needed. Often the result is quite effective.

What will be the result

From this treatment, the driver will receive many positive factors:

- increase the life of this node;

- eliminates the beating of brake discs, which interferes with quality driving;

- braking performance returns, stopping distance decreases;

- finances are saved on the purchase of new products, while the quality of work is not reduced.

If you don’t sharpen and buy, then you need to take a couple of discs at once to the problem axis. This requires an update and pads. What will be the additional expense.

Work

In contact with the disk, the pad itself wears out and cuts weak grooves on the surface of the disk. Subsequently, they become deeper. Due to the fact that the block begins to rub not all of its working area, but only along the crests of the cut grooves, the efficiency of the brake system decreases. Removing the ridges, we will return a large area of contact, and the quality of braking will increase.

Use of machine tools

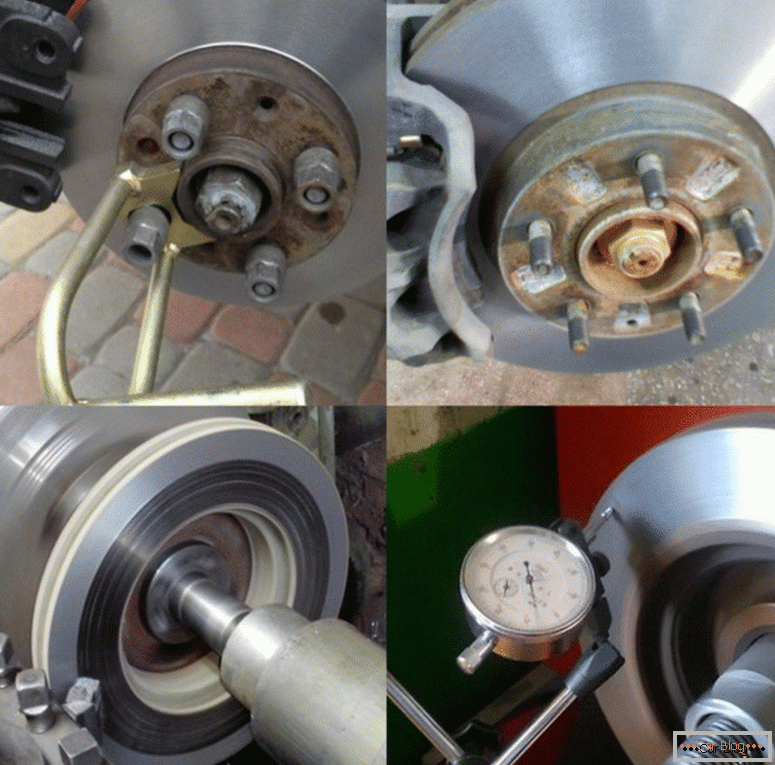

Before you grind the brake disc with your own hands using a special machine, you must remove the wheel. To do this, jacking the right side. Next we connect the rotating part of the equipment to the bolts or studs. At the stationary elements of the wheel assembly we fix the work unit that will align the surface.

The entire machine fits on a small trolley, which is conveniently rolled up to each of the wheels alternately. Work with each wheel takes no more than 10 minutes. PRO-CUT equipment is popular. Processing parameters are controlled by the screen.

See also: Why brake pads creakThe convenience of this method is obvious:

- no need to disassemble muchenough to remove the wheel;

- received accuracy comparable to new factory settings beats and surface cleanliness;

- processing speed and control the result at any second of the process.

Also used groove with the removal of the brake disc. In this case, you will need a special mandrel on which the disc will be based to minimize the beating. If everything is done neatly on a lathe, then you can do without additional balancing. If the beating is more than 0.1 mm, then it is necessary to re-process.

Work improvised means

For those who have no desire or ability to carry out processing with the help of the machine, then you can use an ordinary file or a grinding bar. It is more convenient to work with a file with a disc removed. The main task is to accurately fix the disk in the yew and control the thickness in the treated plane. However, this method will give poor results and lead to the appearance of a heartbeat.

A more effective method is the treatment of non-removable brake disc. To do this, jack up the desired axle of the car and remove the wheels. We start a car and progazovyvay in top gear. At the same time, the partner touches the surface of the disk with a file or a coarse-sharpened grinding stone.

The method gives less beating than with manual file processing. It is necessary to adjust the pressure so that it is approximately the same, not allowing the tool to crash deep into the disk body. Such work takes 20-30 minutes.

After the groove, it is advisable to wash the surface of the disc with a solvent. It is strictly forbidden to use oil or oil cloth for washing, so as not to reduce the coefficient of friction.

Conclusion

Work on the groove of the brake discs can be done independently, even in garage conditions. It is possible to do with a small set of tools and return the effectiveness of the brake system, responsible for the safety in the car.