Reduced performance of the car can be due to many factors. Therefore, the "treatment" of such a disease must be chosen correctly. A significant factor is the level of compression in the combustion chambers of the cylinder block. For such a diagnosis is suitable replacement piston rings.

Additional signs will be the waste of engine oil and the reduction in efficiency with the fuel consumption of the car. A more accurate picture will give a measurement of compression with the help of special devices.

Content

- 1 Measuring compression in cylinders

- 2 Engine disassembly for ring replacement

- 3 Check rings and pistons

- 4 Installation Procedure

- 5 Necessary actions after installing the rings

- 6 Errors when installing the piston rings

Measuring compression in cylinders

Consider the example of work on the classical models of the WHA. Measure compression is necessary on a warm engine. Indications cold motor can distort the picture. For measurements you will need a special pressure gauge, equipped with a threaded tip. It can be bought at any auto shop.

Appearance of the compressometer

Begins checking with twisting all the candles from their nests. Then the central cable from the ignition coil is disconnected. Install a neutral gear and turn the throttle to the maximum opening. After that, the compressometer is screwed into one of the candle holes. At this time, the assistant must crank the starter handle. Two or three pitching will be enough.

The readings are considered normal if the device was installed data 12-13 ks / cm2.

Levels from 10 to 12 are also allowed. But if the numbers were below 10 kg / cm2then this indicates low compression. If the compression still reaches a satisfactory level, but a little late, then in this case the responsibility may be on the valves.

To clarify, you can pour about 20 ml of oil into the controversial chamber and spin the starter again, measuring it. When establishing normal compression at 12 kg / cm2The reason lies in the rings. It can solve the correct installation of piston rings. If the pressure remains low, then valves are the cause of the decrease.

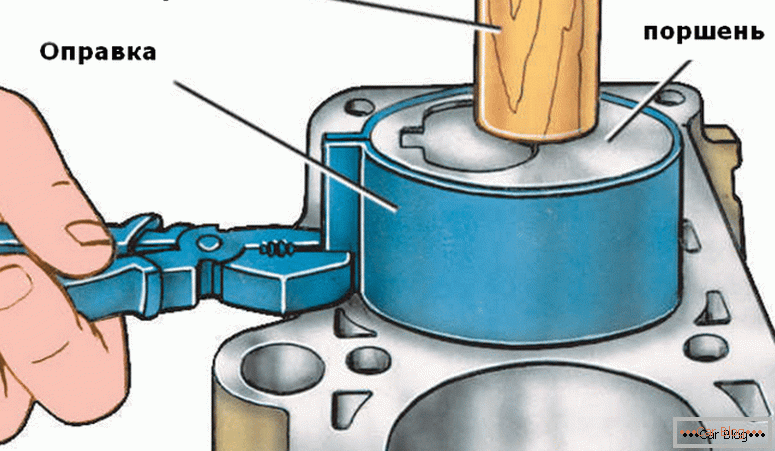

Mandrel mounting

Engine disassembly for ring replacement

Before replacing, you must perform a number of preparatory work:

- It is necessary to drain used motor oil, because after installing new rings, you need to fill in with fresh working fluid;

- carry out the weakening of the exhaust pipe of the muffler;

- it is necessary to remove the valve cover and set the engine according to the marks;

- dismantle the camshaft star, and in front-wheel drive VAZs, remove the bolt of the belt drive pulley, and then the timing belt with the pulley;

- in the classic we weaken the tensioner, and then also dismantle the chain and the star mounted on the camshaft;

- then dismantle the rocker with the springs, putting everything in the correct order to assemble the parts into place;

- remove the head of the block, before you need to disconnect the collector;

- unwind and dispose of the pallet and oil pump;

- remove the connecting rod caps, and then push the connecting rods upward so that you can pull them out with the piston.

Check rings and pistons

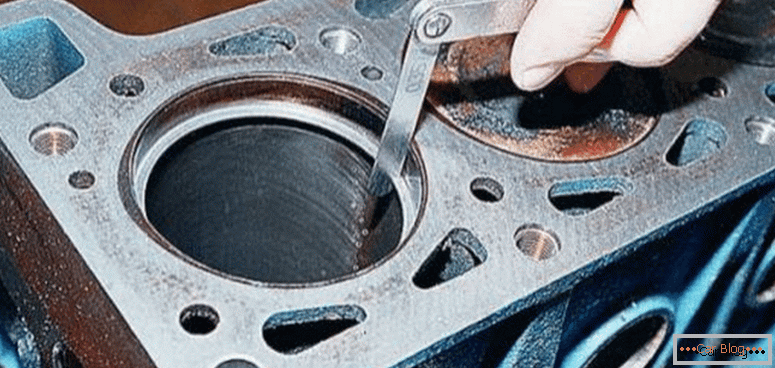

Each ring from the pistons is removed and checked in its cylinder. In order not to confuse them with each other, it is necessary to immediately lay out the details in a certain order. When checking old rings, their outer diameter should not create a gap with the walls of the cylinder more than 1 mm. For comparison, you can insert in the same cylinder a new ring.

Checking the thermal gap in the rings

Measurements will usually be more accurate in the upper part of the block hole, since wear is minimal.

The gap can be checked in special calibers. It is necessary to pay attention to the thermal clearance in the piston rings, which should be in the range of 0.25 to 0.45 mm. It can be checked with a probe. If the parameter is less, the gap can be increased by filing the end plane with a diamond file.

The diameter of the pistons is checked at the bottom (skirt). This is done with a mic.

It is necessary to compare this indicator with the table of acceptable values. Additionally, you must check the gap between the piston groove and the ring. In case of excess, the pistons must be replaced. The tolerance limit is 0.15 mm. Pistons are also checked visually for cracks and integrity of lintels for rings. After flushing, satisfactory pistons can be used further.

Installation procedure

Branded products of proven manufacturers have convenient labeling, thanks to which it is clear how to properly install the piston rings. “TOP” is written on one of the sides, which means “top” in English. This side should be directed towards the combustion chamber or the top of the piston.

Mark on the sides of the rings

If no inscription was found, then there should be a groove along the entire diameter. This step should be turned down the ring.

Usually two installation methods are used. One of them is safer, and the second is more often used either by great professionals or absolute beginners. Both are suitable for self-application during repair.

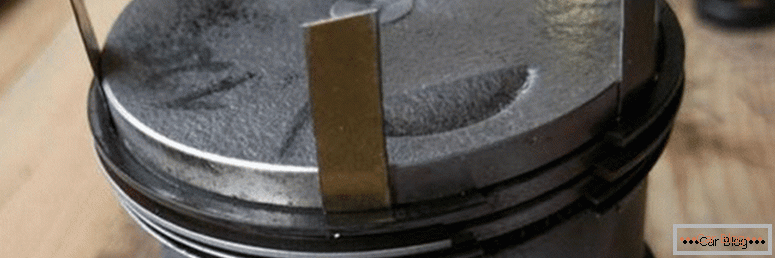

Installation using metal plates

In the first case, you need to cut a few flat pieces of tin, with a thickness of approximately from 0.3 to 0.5 mm. Three or four of these sheets have a piston diameter. Rings are put on them. And fall to the level of the slot. Then the mandrel for piston rings is removed from the plates, and the ring sits in the desired groove. The method is perfect for any master.

Piston ring mounting

The second option requires a certain amount of experience and skill. It lies in the fact that you need to dissolve the gap with your fingers, increasing the inner diameter of the ring to the extent that the piston passes through it and is installed in the desired groove. The downsides are that often inexperienced locksmiths break a lot of rings, using more force than necessary.

See also: Blue smoke from the exhaust pipe of a diesel engineNecessary actions after installing the rings

When each ring has taken its place in the groove, then you need to install slots about 120 degrees from each other. This reduces the likelihood of gas breakthrough from the fuel chamber into the crankcase cavity.

Incorrect installation of piston rings

There is evidence that the first ring holds about 75% of all compression, and the second - about 20%.

If thermo gaps are divorced, then when a certain amount of gas breaks through the first ring, it will not have time to get further, unlike the closer position of the second gap.

Errors when installing the piston rings

Installing new rings in worn cylinders is absolutely not effective. This is due to the fact that the worn hole has the shape of an ellipse. Expected quality lapping cannot occur.

Piston Ring Set

Also at high speeds the second ring, consisting of cast iron, can trivially burst.

During operation of the ring in the grooves stuffed production. Such gaps seal off the combustion chamber and gases from it enter the crankcase. And in the opposite direction comes the oil. Such a design can work out a few thousand kilometers, and then again it is necessary to carry out repairs.

Also, a gross mistake will be the conscious installation of gaps opposite each other. Gases overheat one side of the piston, and it turns out deformed part. There is a burnout of the metal and additional deformation of all elements.