>

When any part of the car fails - it is always unpleasant. But there are nodes, the inoperability of which may affect driving safety. As an example, you can call the head optics. Muddy from old age glass headlights - this is not only discomfort while driving, it is a real danger in time not to notice an object that could cause an accident. The loss of tightness due to the presence of cracks and other defects on the glass of the headlamp also faces no less troubles: in this case water will inevitably fall into the glass and, as a result, glass will mist over.

Loss of tightness of headlights threatens the driver

Glass replacement is an operation that requires the use of a special sealant, which is precisely to ensure the perfect sealing of the joint. It turns out that the choice of sealant for car headlights is not easy, because there are several varieties of these materials, which differ not only in physical and chemical characteristics, but also in their sphere of use. A novice motorist, without knowing the relevant nuances, risks to do this job not with proper quality, which threatens to break the glass in a few months, or even weeks.

To avoid such a scenario, we suggest to get acquainted with a small overview of the types of automotive sealants, as well as offer you a small rating of the most popular ones and describe how to properly remove and apply sealant when replacing glass headlights.

Types of automotive sealants

The maintainability of the glass is well known - this material is practically not subject to recovery in the event of various defects. Transparent plastic, which is increasingly being used as an alternative to glass, allows the splitting of broken parts, but such repairs are not practiced - the cost of a new product is not so high. The main thing - to ensure the most tight connection of parts, especially when it comes to car headlights.

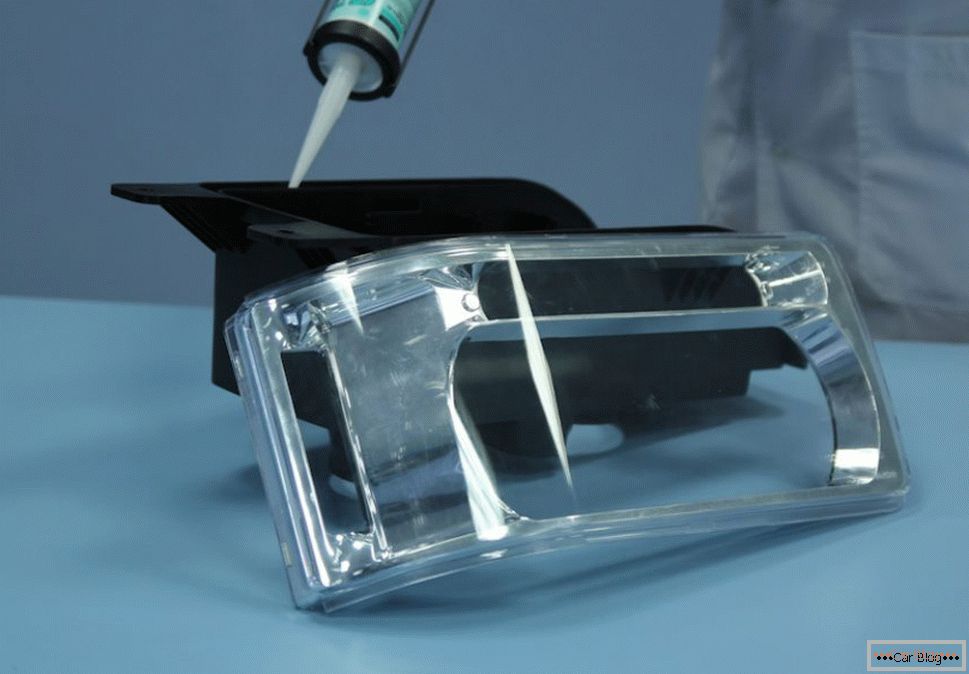

For their minor repairs and installation of glass or plastic glasses, special waterproof adhesives and sealants are used. This material is designed to perform two main tasks:

- ensure reliable mechanical connection of the parts to be glued;

- seal the seam, preventing the penetration of water and air through it.

At present, a sufficiently large range of sealants is on the market, most of which, including automotive ones, are able to glue not only glass or plastic. Materials such as ceramics, wood, metals, leather, textiles can also be processed with modern adhesives, sealants, but we are only interested in those who are able to ensure the replacement of car headlights with proper quality.

Of course, the quality of bonding depends on the physico-chemical characteristics of the sealant itself, and on the skills and abilities of the worker. In any case, the lack of complete sealing of the seam means the possibility of air and moisture penetrating into the interior of the headlamp, which will contribute to the formation of condensate that accumulates on the glass itself and all other internal surfaces of the illuminant.

The deterioration in the quality of lighting is not the only negative point of this process: under conditions of high temperature inside the headlight, the condensate will corrode the diffuser itself and all metal parts, which is much worse.

Sealants for pasting car windows may have a different composition, but single-component compositions are the most common, most of them being offered in a ready-to-use form that does not require any other manipulations with the sealant. If the sealant is a viscous fluid, in many cases it is offered in a container equipped with a dispenser. Pasty sealants to give the necessary properties must be diluted with a special composition, which is also present in the package.

The classification of sealants according to their composition and physical properties includes four large groups:

- silicone,

- polyurethane,

- heat resistant

- and anaerobic materials.

Consider the main characteristics, advantages and disadvantages of each of their groups.

Silicone sealants

Этот материал, обеспечивающий надёжную герметизацию таких деталей автомобиля, как фары, фонари, передние и задние окна и верхние люки, представляет собой эластичную, но очень надёжную прокладку между склеиваемыми поверхностями. Silicone sealants изготавливают из специальных разновидностей каучука (силоксановых, фторсилоксановых, кремнийорганических). Вулканизирующие добавки, входящие в состав таких материалов, при взаимодействии с водой приобретают упругость и эластичность, свойственные резиновым изделиям, но при этом обеспечивающие надёжное склеивание двух соприкасающихся поверхностей. Силиконовый герметик для автомобильных фар пригоден как для склеивания поверхностей, так и для заделывания трещин глубиной 4 – 6 миллиметров. Благодаря эластичности каучукоподобного материала можно устранить все неровности и дефекты сопрягаемых деталей.

Conventional silicone sealant is able to retain its performance when exposed to temperatures up to 250 ° C, heat-resistant varieties have an upper temperature limit that does not affect the properties of the interface, 100 degrees higher, and compositions that include copper filler are able to withstand temperatures of 375º C.

The main disadvantage of silicone adhesives is their instability to the effects of many ethylene glycol-containing materials actively used in the car (engine, gear oils, gasoline, antifreeze). Therefore, the scope of their application is limited and does not allow the use of silicone sealants in radiators, gearboxes, assemblies of the power unit and the fuel system.

Polyurethane sealants

Compounds based on polyurethane fillers are considered the most versatile and common, so they are used for sealing car headlights and many other body parts (glass, plastic, metal).

Polyurethane sealants most common

This type of material is characterized by excellent adhesion (the ability to "stick" to any surface - wood, concrete, plastic, metal, glass), as well as 100 percent water resistance and airtightness. The hardness of the polyurethane sealant is also unique; therefore, in cases where it is necessary to ensure the sealing of collapsible joints, it is not used - otherwise there will be serious problems with dismantling and cleaning the surface.

Other advantages of this material:

- the ability to provide the function of sealing compounds in a wide range of temperatures, from minus 60 to plus 80 degrees Celsius, which allows the use of polyurethane compounds in all climatic zones of our country;

- according to manufacturers, this type of sealant is able to retain its performance properties for a quarter of a century;

- polymerized polyurethane is characterized by high resistance to most aggressive substances (alkalis / acids, fuels and lubricants, etc.), which allows it to be used for sealing any car parts that are not subject to frequent disassembly;

- increased resistance to fungi, mold and other harmful microorganisms, eliminating the need for additional processing of sealed compounds with appropriate antiseptic compounds;

- good elasticity, allowing the polyurethane sealant to glue the glass headlights of the car of any geometry - the composition fills all the seams and crevices evenly, without shrinking after complete polymerization;

- Also known is the ability of the polyurethane material to spring up under deformation effects, which allows its use in areas with increased seismic activity (according to test results, the seams filled with this material are able to withstand seismic shocks of magnitudes up to five on the Richter scale).

This material has disadvantages. From the point of view of environmental safety, not everything is good here: toxic components are included in the composition of the polymer, so that when working in sealant it is necessary to observe certain safety measures. In fairness, we note that after polymerization, all substances harmful to health are bound, which allows the use of compounds made of polyurethane sealant even in construction, and even more so when repairing a car.

The material is destroyed when exposed for a long time to temperatures from 120º C and above, which should be considered if necessary to seal high-temperature connections.

Finally, the disposal of polymerized material is a rather time-consuming and economically impractical procedure. Polyurethane sealants are more expensive than silicone and acrylic counterparts, and yet it is considered the most optimal material for repairing car headlights.

Anaerobic seams

A characteristic feature of anaerobic sealing materials is their ability to maintain their plasticity for an arbitrarily long time - provided that air is freely accessible. If you limit the access of oxygen to the treated surface, the anaerobic material begins to quickly solidify. The scope of application of this type of sealants is the creation of gasket layers, as well as the sealing of flanges, threaded connections, and joints. In terms of resistance to aggressive materials (oils, gasoline, antifreeze), the material will give odds to silicone sealants, while the polymerized layer is able to withstand working temperatures of about 90-175º C.

The sealant is a liquid that, being pressed between two flat surfaces, without air access, quickly turns into a solid and durable plastic that does not expand and does not shrink.

The main advantage of this type of sealant is the ability to create completely sealed connections without the need for exposure to extraneous factors (mechanical pressure, high temperature, twist, etc.). Such a glue for repairing car headlights is absolutely safe, and those residues resulting from its use can be collected with a suitable tool and reused.

Heat resistant sealants

As the name implies, heat-resistant compositions are used when it is necessary to seal joints exposed to very high temperatures (up to 375º C). At the same time, the strength characteristics of the seam are very high: neither vibrations nor mechanical effects will be afraid of it.

As a rule, heat-resistant sealants are sold in the form of two-component compositions, the consistency of which can be either pasty or solid. The most significant disadvantage of heat-resistant sealants for car headlights is that it takes a long time to polymerize (usually from 8 to 12 hours).

Rating of the best sealants for automotive headlights

Each of the types of adhesives is characterized by its own set of advantages and disadvantages; therefore, it is quite difficult for a non-specialist to determine which sealant is better. But the car "professionals" when choosing a sealing compound have to choose from the mass of proposals, many of which are new materials for them. So the problem of choice is quite acute. Guided by the numerous reviews of motorists and the advice of specialists in car repair, we risk compiling a small rating of the best sealants for repairing car headlights.

APRO AS-904

One of the most popular materials is adhesive tape, sold in roll form. This sealant is a vulcanized polyisobutylene - a material characterized by excellent elasticity. One APRO AS-904 package worth up to 500 rubles is enough to completely seal the two front or rear block headlights.

Adhesive tape of excellent elasticity - APRO AS-904 sealant

The design in the form of a tape is very convenient for installation: to handle the headlight, it is necessary to cut a piece of tape of the required size, and then stretch it so as to obtain the required thickness. Next, the tape is applied to a sealed surface, previously carefully degreased, so as to fill all the existing irregularities and gaps. The ends of the tape are simply pressed against each other - a few seconds is enough for their gluing (polymerization). It is recommended in cold weather to pre-heat the sealant with a hair dryer to 18 - 22º C.

APRO AS-904 податлив в работе, к рукам не липнет, особенно если смочить руки перед началом работы водой.

Advantages of sealant:

- an excellent indicator of adhesion to a sufficiently large range of materials;

- the tape is characterized by ease of processing; it can be stretched to the required thickness without applying excessive force;

- material differs from analogs in the absence of unpleasant odors;

- solidification rate is very high, almost instant;

- the polymerized material is very durable and provides a reliable and completely tight connection.

Dow Corning 7091

This sealant has a chemical formula that is specifically designed for use with materials that are characterized by unequal thermal expansion properties, which allows it to be used for processing such pairs as metal - plastic, glass - plastic, glass - metal, that is, it is an ideal sealant for glass car headlights.

Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru Dow Corning 7091 - Representative Silicone Sealants

adom.ru Dow Corning 7091 - Representative Silicone Sealants

Dow Corning is one of the best representatives of the class of one-component silicone sealing compounds, it is characterized by excellent elasticity, high adhesion rate against a large range of materials, as well as excellent strength of the polymerized seam. Many experts recommend this sealant as an ideal material for the treatment of automotive headlights, electronic and electromechanical components, LED lamps and other parts that require reliable mounting and sealing.

Differs in convenience in work and fast polymerization, does not demand preliminary processing of a surface. It can be operated in a fairly extensive temperature range (ranging from minus 55 to plus 185 degrees).

Advantages of Dow Corning 7091:

- bonding / sealing a wide range of heterogeneous materials;

- good indicator of frost resistance / heat resistance;

- ease in processing sealant;

- high elasticity of the material;

- fairly rapid curing;

- excellent seam strength;

- in the polymerized state, the sealant is a reliable dielectric.

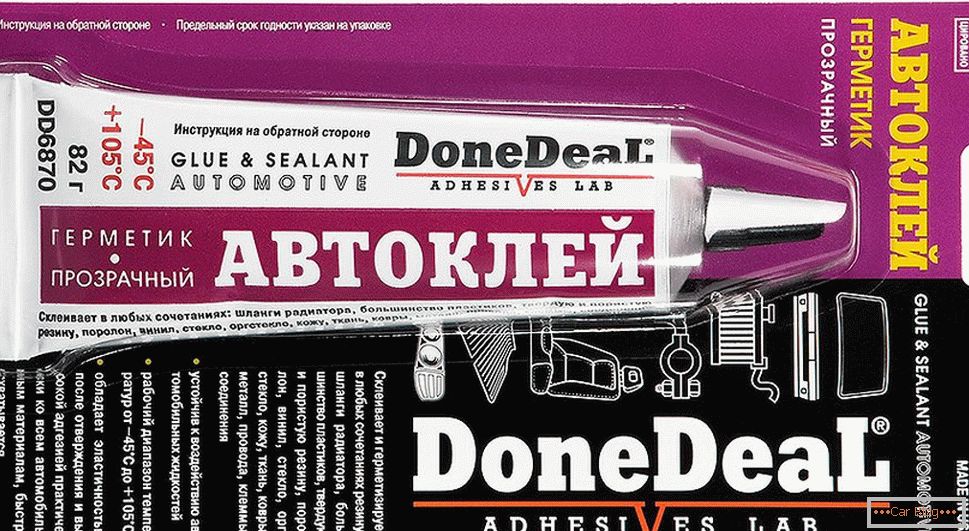

DoneDeal DD6870

Transparent polyurethane sealant for universal use, produced using petroleum distillates (methyltriacetoxysilane, methyl ethyl ketone, ethyltriacetoxysilane, toluine) and a complex of special polymer additives.

It has a good resistance to a large range of aggressive substances, which allows the use of DD6870 for sealing / gluing car lamps, headlights, hatches, glass, as well as an alternative to standard gaskets made of hard materials.

It is characterized by an average solidification time (15 - 30 minutes) and the possibility of operating in a wide temperature range (from minus 60 to plus 270 degrees).

Полиуретановый DoneDeal DD6870 sealant

Advantages:

- high mechanical strength of seams;

- excellent moisture resistance of the material;

- good adhesion rate;

- the ability to maintain their properties under the influence of vibration.

Эфиматика РВ

Sealant belonging to the class of one-component polyurethane compositions. Sold in tubes weighing 300/600 grams. The price for a 300-gram tube, which is enough to handle one - two block-headlights - up to 500 rubles.

For the treatment of headlights, you need to have an air pistol available; when processing parts, the best results are achieved when they are pretreated using a primer and a cleaner.

Sealant with one component composition

Advantages of sealant:

- no unpleasant odors;

- excellent seam strength;

- low cost;

- ease of operation, elasticity of the source material.

We hope that this rating will help you determine which sealant is best for handling car headlights. Note that the methods of application can vary significantly - instructions for use are usually present on the package or attached with the sealant.

Removing old sealant

The main problem in the repair of automotive optics is the removal of old (standard or applied during repair) sealant.

Typically, this is done using a technical dryer, with which the material is preheated (the usual female dryer will also fit). It is important not to overheat the old layer, as the plastic may suffer (deform under the influence of high temperature).

The technology of removing the sealant implies its sequential removal in small areas - otherwise it will have time to cool down.

Heated sealant can be removed either with a sharp knife or with a screwdriver with a wide flat blade. You should not be afraid that you may accidentally scratch the plastic with the edge of the tool - this place will still be hidden by a layer of sealant, and scratches will only improve the adhesive properties of the adhesive.