Increasing the price tag at the gas station for gasoline and diesel fuel makes motorists think about ways to save on travel. One solution to the problem is to use different alternatives to liquid fuels. We have to study the device HBO 4 generations to translate his iron horse to gas consumption.

Content

- 1 Features of gas equipment

- 2 Basic principles of work

- 3 Using indicators

- 4 Schematic work of HBO and its device

- 5 Positive characteristics

Features of gas equipment

Manufacturers in our country and abroad offer consumers the fifth generation of HBO, however, motorists prefer the time-tested system of the previous version. This is connected not only with the high cost of the new system, but also with its maintainability and running in different situations.

The main task of using gas equipment is to supply a mixture of gaseous fuel and air into the working cylinders of the internal combustion engine.

Modern gas installation 4 generation can be installed on various types of transport:

- a car;

- trucks;

- minibuses;

- public transport;

- commercial cars, etc.

There are two main types of systems on the market:

- Compressed (CNG). Compressed natural gas is used (methane CH4).

- On liquefied petroleum gas (GOS). The kits are used individually or a mixture of propane and butane (C3H8 and C4H6 respectively).

It is believed that methane will be more dangerous. Even a small amount of this chemical is capable of causing rapid poisoning, blindness, suffocation, etc., in a person. The gas molecule is smaller than that of the GOS, so it requires thicker and more tight gas pipelines, tanks, etc.

Basic principles of work

Since the 4th generation HBO works in the combined fuel + gas mode and in the mono-fuel cycle (exclusively gasoline or exclusively gas), motorists can independently choose their preferred driving option at a particular moment. This feature makes the system very popular among car owners.

There is also an automatic mode for switching between types of fuel. Designers have developed a fairly small in size control panel. It has a LED backlight where you can learn from the indicators about the amount of fuel in the tanks..

Often the mounting panel is on the left side near the steering column. This zone is ergonomic for comfortable handling.

Using indicators

Engineers have provided on the panel of the 4th generation a row of 4 green indicators, culminating in one red light. This element was transferred to the 5th generation.

To navigate the signals is simple. It is only necessary to take into account important factors:

- one burning green light corresponds to approximately 10 liters of gas;

- a ten-liter portion of gas fuel lasts an average of 200 km;

- a red lamp that has ignited indicates a power reserve limitation of 40-70 km;

- with a burning red LED it is worth going to the gas station as soon as possible.

There is a separate red LED that is either extinguished or is operating in a blinking mode. In the first case - the car runs on gas. When the engine is blinking, only gasoline is burned and automatic switching to gas is expected.

See also: Making the electric trunk lockThe red LED lights up at the start when the car consumes gasoline. After reaching the operating temperature mode, after a while, the transition to liquefied fuel occurs.

It should be borne in mind that when gas equipment of the 4th generation has the ability to work in combined modes, this indicates an increased system reliability and an additional engine reliability. An important factor is the elongated mileage of vehicles, provided by refueling several types of fuel.

Actual gas transport is for small settlements where there is a risk of refueling with poor-quality fuel or gas stations are located far enough. Car owners themselves admit that cars with gas appliances steal a little. It is enough for the driver to withdraw the switch and the car will not start on either gasoline or gas.

When a motor with a fairly expensive injection system, including a catalyst, is present in the car, the introduction of HBO will have a positive effect on the flow rate and will objectively prolong the operating period of the catalyst.

It is important to know that gas installations of the 4th generation are actually installed on vehicles that meet environmental standards not lower than Euro-3 for harmful emissions, because there is a pulsed injection type for a mixture of fuel and air, performed by the commands of the controller of a separate management unit.

The computer reads and generates processor data, sending management impulses. The latter help to open the gas injection nozzles and block similar nozzles for gasoline. The system is based on a specific type of data, which include:

- the current temperature that the gearbox has;

- current gas pressure;

- inlet gas temperature.

During operation, the gas pressure level may drop significantly. In such a situation, gas equipment in an automatic mode will close and block the operation of gas injectors, and in parallel to open and operate gasoline counterparts.

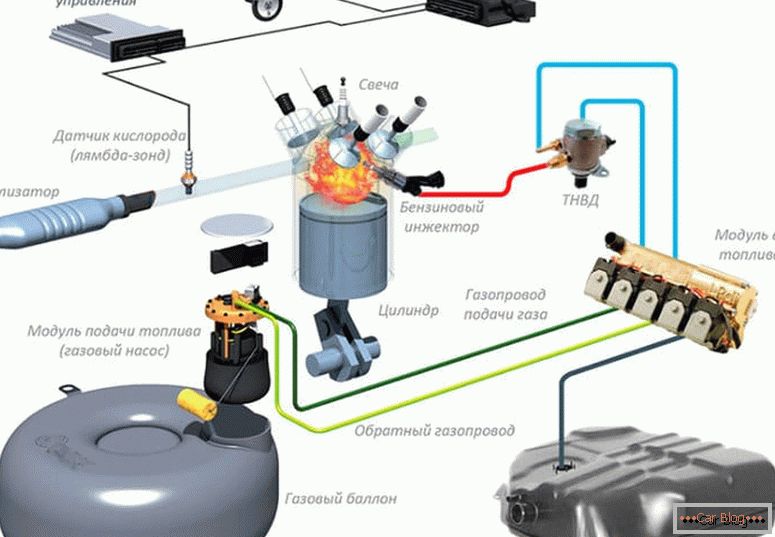

Schematic work of HBO and its device

The mandatory attributes of a gas kit are the following components:

- multi-valve;

- capacity for storage of liquefied gas;

- module for the preparation and injection of the fuel mixture into the cylinders.

Installation of multivalve is carried out on the throat of the cylinder. It is used to provide refueling capacity and to control fuel consumption during the gas-consumption cycle. The multivalve consists of the elements:

- flow valve (exhaust);

- filling valve (inlet);

- emergency valve (used for quick pressure relief);

- analogue capacity full indicator;

- refueling tap for fuel.

The need for an emergency valve is that it helps shut off the output channel if the gas flow rate increases dramatically. Such a factor manifests itself, for example, when the diverting pipes to the engine are damaged.

The module for the preparation and distribution of gas has the following design:

- Fuel rail with working jets.

- Cleaning filters.

- Gearbox.

Single-stage gearboxes are used for propane structures, and two-stage analogues are relevant for methane systems. Thanks to this node, the fuel is transferred from the liquid phase to the gaseous phase. An additional feature of the two-stage models is to reduce the output pressure.

See also: GSM alarm system for autoIt is preferable to start engines with mixed fuel systems on gasoline to reduce the effect of detonation. You can also use gas for this, but it is worth doing it only in emergency situations.

Frequent start on gas is able to disable gearboxes. The diaphragm built into them receives high overloads when the motor is made due to high pressure. After starting on gasoline, the working temperature rises, and the automation switches the work to gas. The reduced pressure forces the automation to transfer to liquid fuel, and the driver beeps.

The work of the fourth generation HBO does not allow in the input channel pops appearing in systems that are poorly synchronized with the mechanical feed. This reduces the risk of working on internal combustion engines with plastic headers.

After installation, you will need to provide a quality ignition setting. This is due to the fact that the gas has a significantly higher octane number, when compared with gasoline. The gas block needs an earlier ignition, which is reflected in a larger advance angle.

It should be borne in mind that significantly improve the work of HBO allows the use of special spark plugs. However, it will work on the classic NW of the internal combustion engine. Setup is performed by introducing electronic variators.

The system of the 4th generation allows for upgrades and tuning. To do this, use the chip tuning engine. Thanks to optimization, it is possible to balance the temperature operating mode, in which the automatic switching of the fuel supply will occur.

We recommend to take care of the presence of dopfilters that help protect the gearbox with nozzles from mechanical impurities. This will significantly extend the life of the module and provide less load on the engine.

Positive characteristics

The advantages of the 4th generation HBO compared to earlier modifications include the following factors:

- maximum power is generated due to precise fuel metering and optimal mixing ratio;

- jerks of internal combustion engines are eliminated, work proceeds smoothly without undue friction and claps characteristic of the previous generation are excluded;

- fuel combustion occurs to a greater extent, which leads to increased environmental friendliness, compliance with Euro 3/4 standards, with a minimum loss of power by 1 + 2%;

- designers took care of the introduction of unique connectors that are not confused during installation, which simplifies and speeds up the assembly;

- thanks to hardware diagnostics and software pairing, the 4th generation is perfectly installed on modern cars.

In any city it is easy to find masters who will help with setting up and solving technical issues with this equipment. The price tag on it is available to most users.

During operation, the performance of the internal combustion engine may deteriorate for the following reasons:

- broken gear;

- lost settings of the dispenser or gearbox;

- the filter was operated for a long time and clogged, which led to a decrease in fuel supply;

- in winter, the temperature of the gas mixture is lowered.

It is worth considering that in cold weather the motor may consume the re-mixed mixture. This happens because of the reduced temperature.