"Samara" (VAZ 2109), in itself - the car is durable and reliable. And if something “flies”, it is usually the result of extreme temperatures, or improper operation. But time does not spare anyone, even cars. Therefore, one day it may simply not start. And the reason for such a malfunction may not be in the engine, or ignition. Often to such damage leads to failure of the valves.

Valve Inspection & Repair

Valve check is a mandatory process in vehicle diagnostics. It will help weed out some variants of the causes of the malfunction

Often it happens that the needle valve carburetor VAZ 2109 sometimes can just "stick". And this causes problems. If the fuel needle valve is faulty, it must be cleaned or replaced.

It happens that the valve stops working in very hot weather. This can be expressed in the fact that the car starts, but after ten to twenty seconds the engine stalls. Externally, to determine the cause is very problematic.

Sometimes in such cases, tapping on the carburetor cover helps, and then several strokes are made on the manual drive of the fuel pump.

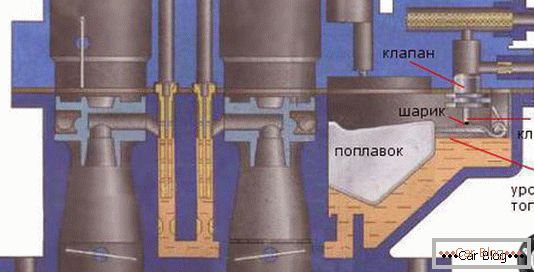

When the needle valve stops its operation in the closed state, then apparently nothing happens and you will not hear any sounds. And the open valve gives the sound of gasoline that fills the float chamber.

The process of replacing the needle valve carburetor VAZ 2109

We recommend not to mock the car and replace the valve. Otherwise, sooner or later, you will have to do a more serious repair of the carburetor VAZ 2109.

Attention! Replacement is carried out only on the cold car.

- It is necessary to loosen the bolts securing the cable and braid of the drive “suction”. After that, it can be freely removed from the carburetor.

- Now you need to stop the clamps to remove from the carburetor hose that brings gasoline and "return line". You can disconnect the wire from the valve economizer forced idling.

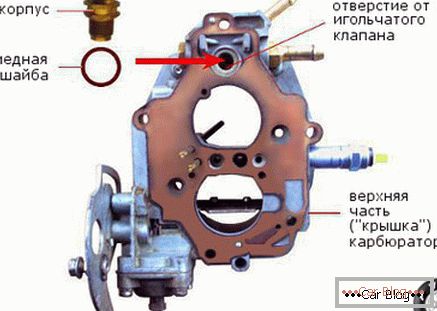

- When you do this, you need to unscrew the five screws that secure the carburetor cover. It is very important not to damage either the gasket or the floats. Now you can remove the cover.

- Turn the lid over so that the floats are at the top. After that, you can take an awl and push the axis of the floats to remove them. We do everything carefully, in order to avoid damage to the tongues. Otherwise, the fuel level may be disturbed.

- Now remove the old valve. New ones are made in such a way that its needle is essentially a separate part. This is very convenient because now, the bridle is easily put on the tongue.

- Be sure to soak a new needle for ten minutes in gasoline, before you begin installing a new valve.

- Attach the new valve.

- The needle is put on the tongue bridle. At the same time it is inserted into the case itself. Next, the floats are installed, with the combination of the holes under the axis of the bracket and the floats. We return to the rightful place axis floats.

- Now the cover can be returned to its place. But ideally, wash the fuel filter as well. To do this, unscrew the plug that is located opposite the inlet and pull out the filter. After that, it is washed in gasoline and put in place.

- Twist the screws on the carburetor cover.

- We return to the place of the hoses and cable, fasten.

After that, problems with sticking of the valve will definitely not be. If necessary, check the carburetor solenoid valve VAZ 2109.

Checking the carburetor solenoid valve VAZ 2109 and its control unit

In the carburetor VAZ 2109 installed solenoid valve and its control unit. This unit turns on the valve at 1900 rev / min and shuts off at 2100 rev / min. As soon as the engine reaches the specified crankshaft rotational speed, a break will occur in the electric supply circuit of the carburetor solenoid valve VAZ 2109 and the supply of gasoline will stop.

Conversely, when the rotational speed drops to 1900 rpm, the circuit closes again and the fuel supply is restored. In order to check the correctness of the operation of the solenoid valve VAZ 2109, follow these steps:

- turn on the engine and warm it up to operating temperature;

- then you should disconnect the connector from the valve wire and close it to ground;

- Gradually increase the engine speed to 2100 and lock them at this point.

- when the engine reaches 2100 rpm, you will feel the appearance of a self-oscillating mode with a ripple of revolutions. This is due to the fact that the supply of fuel has stopped - the valve is closed.

- as soon as the valve is closed, then a natural, gradual decrease in revolutions to 1900 revolutions follows, and as soon as this mark is reached, the solenoid valve automatically opens and the fuel begins to flow into the engine again - the revolutions up to 2100 rpm will begin.

In most cases, the valve on / off mode is a cyclic process and occurs every 1-2 seconds. So, if you didn’t see this cyclical process while checking, but you are sure that the valve is working, then you should deal with the control unit. Or change the valve to a new one for more confidence.

Recommended article: VAZ 2114 dashboard (designation, description and diagram)

To check the control unit of the VAZ 2109 carburetor solenoid valve, an additional wire should be prepared, the length of which should be enough from our valve to the battery, namely to the positive terminal. In addition, the required voltage indicator lamp. Next you need to do the following steps:

- disconnect the power cable from the VAZ 2109 carburetor solenoid valve and connect the valve to the battery terminal with the previously prepared wire without disturbing the motor;

- Connect the supply cable of the valve that was disconnected to the positive terminal of the test lamp, and the minus to the ground.

- start the engine and let it idle at a crankshaft rotational speed of 850-900 revolutions per minute, and the test lamp should be on.

- gradually increase the speed to 2100 speed and the lamp will go out when it reaches this mark, and reducing the speed to 1900, it will come on again.

At this stage, the testing of the carburetor solenoid valve VAZ 2109 is over. If a fault is found, either the valve or the valve control unit should be replaced.