Автопроизводители стремятся найти оптимальные технические решения во время проектирования различных узлов транспортного средства. AT результате появляются конструкционные новинки. Примером служит эволюция трансмиссии. Сейчас можно наблюдать различные варианты коробок переключения передач, которые успешно конкурируют между собой. Существуют механические, автоматические, роботизированные КПП либо бесступенчатые вариаторы.

AT статье выясним, what is a robotic gearbox, какими достоинствами и недостатками она обладает по сравнению с другими типами трансмиссии. ATедь часто от степени комфорта управления автомобилем зависит не только наше настроение, но и безопасность на дороге.

Content

- 1 What is a box - automatic robot

- 2 How does a robotic box work

- 3 Device coupling in the robot

- 4 Pros and cons of a robotic gearbox

- 5 Conclusion

What is a box - automatic robot

Let's start with the fact that the robot is on withUchi mechanics, in which gears are switched and the clutch is squeezed out by automatics. If we take, for example, a Toyota Corolla on a robot that has been produced since 2007, then it has a robotic box - it’s one in one mechanics, which has the usual gearshift lever and clutch removed and instead of them put special actuators - actuators. From this it follows that the ride quality of the car will be in many respects similar to conventional mechanics, just do not have to switch gears yourself.

The job of these checkpoints is to receive information from the driver in digital form, and then, correctly and quickly processing it, translate everything into mechanical manipulations with gears and shafts. To control the choice of gears instead of the usual lever, which is connected by cables or rods, a lever is used with the box - a joystick, which only indicates to the electronics the necessary gear. The electronic control unit (ECU) is responsible for the logical part.

ATнешний вид рычага управления роботом на тойоте королле

Taking into account user feedback, we note that this type of automotive gearbox has most of the advantages of an automatic transmission and combines the cost-effectiveness and reliability of automotive “mechanics”. For the buyer, the robot will be cheaper than the classic “automatic”, and this means that there is an additional positive argument in their favor.

Most of the popular automakers are engaged in the release of models of various price segments with robotized transmission units installed on them. Even in the budget segment, Renault in 2016 released a car with a “robot” on board.

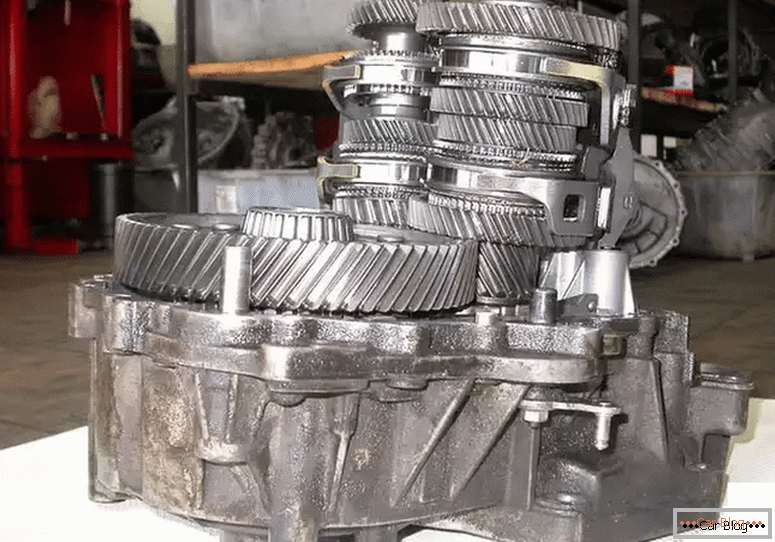

How does a robotic box work

За основу роботизированного блока переключения скоростей в большинстве автомобилей взята механическая КПП. При этом манипуляции с переключением между ступенями занимаются специальные конструкционные надстройки, которые называются сервоприводами. AT некоторых источниках эти переключатели имеют название – актуары. Один из них занимается включением/выключением сцепления, а миссией второго является физическое перемещение шестеренок в коробке. Это значит, что их работа помогает избавиться в салоне автомобиля от педали сцепления.

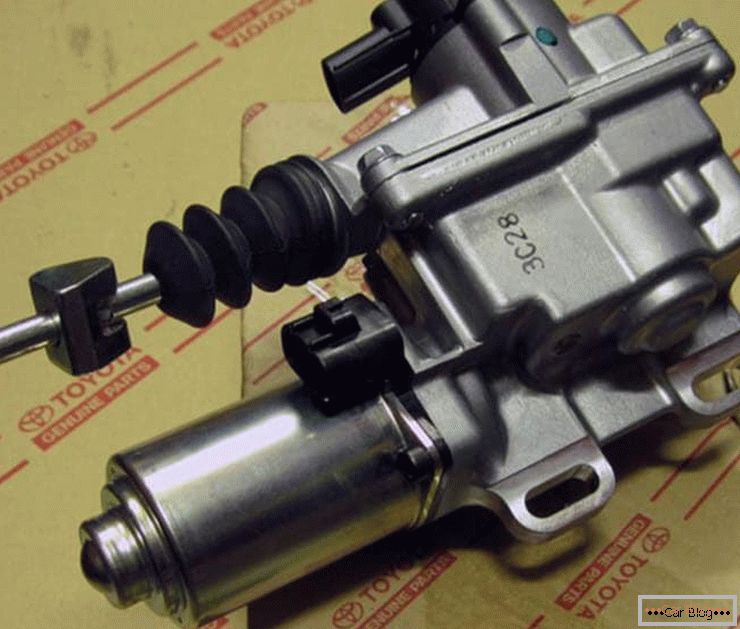

ATнешний вид актуатора сцепления робота

Не все конструкции приводов одинаковые. Инженеры создали две их разновидности. AT первом случае работоспособность поддерживается с помощью электричества, а во втором случае за плавность и быстроту переключений отвечает гидравлика. Обычно отзывы не всегда однозначные, поэтому опишем оба варианта.

- A popular device is electric drive. This design has a lower cost and can even be placed on machines of the budget class. The control is based on an electric motor with a gearbox and an actuator.

- AT hydraulic system Shifting is done with cylinders pushed by the force of the solenoid valves. The principle of operation in this case is similar to the classic "automatic". The second name of such devices is “electro-hydraulic drive”. The design is more expensive than a conventional electric drive, but this is offset by the speed of switching between gears. Also, the driver does not feel the emergence of any sudden failures. The block is placed on more expensive cars.

The management of all operations is entrusted to the built-in computerized node. He monitors the engine speed, the current speed of the car, receives information from ABS, the anti-drip system and gives commands to the actuator.

Clutch device in the robot

Первые «роботы» в автомобилях устанавливались с одним сцеплением. Эксперимент получился неоднозначным. ATыявилось достаточное количество недостатков такой конструкции. AT результате разработок появились КПП с удвоенным сцеплением. Рассмотрим эти типы коробок и их работу.

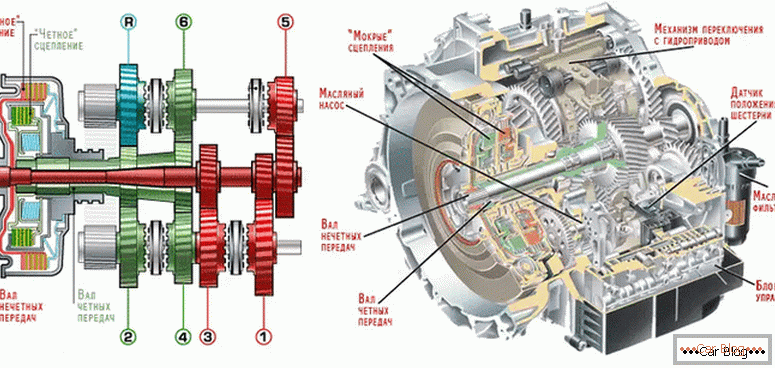

The device of the robot with two clutches

- One clutch. The basis of the gearbox are two shafts: primary and secondary. Rotation from the engine is fed to the primary (driving) shaft. With the engine it shares the clutch. From the secondary (driven) shaft through gears, the rotation is transmitted to the wheels. At the command of the electronics, the first servo disengages the clutch, and the second after the break is engaged in moving the synchronizers in the same way as the driver would have done with the lever on the mechanical box. However, electronics "saves" the clutch, and the power gap often becomes noticeable in the cabin (the effect of passengers nodding when traction is temporarily lost).

- Two clutch. Снизить эффект от негативного воздействия провалов тяги конструкторы попытались с помощью двойного сцепления. AT результате появились конструкции, получившие общее название DCT (Dual Clutch Transmission). Позже концерном Volkswagen были разработаны шестиступенчатые коробки DSG (Direkt Schalt Getrieb). Эта аббревиатура, являющаяся просто товарным знаком, стала синонимом всех коробок с двойным сцеплением, также как слово «ксерокс» вошло в обиход не торговой маркой, а бумажной копией. У DSG в конструкции есть два первичных вала, один из которых находится внутри другого. Оба вала имеют соединение с мотором с помощью индивидуальных сцеплений. «Умная» коробка, запуская автомобиль в движение, включает первую скорость, но одновременно на втором валу входит в зацепление шестерня для второй передачи. ATторой вал ждет замыкания своего сцепления и одновременного размыкания с первой передачей. Это экономит время переключения и обеспечивает плавность перехода между ступенями. Есть второе название таких коробок – «преселективные» (предугадывающие выбор). Например, для автомобилей Гольф время переключения роботизированной коробки составляет лишь 8 миллисекунд.

Инженеры, усовершенствую конструкцию двойного сцепления, разработали две разновидности этого узла. AT первом случае было решено оставить окружение сцепления воздушным («сухой» тип), а во втором случае в узел залили рабочую жидкость («мокрый» тип). У водителей, предпочитающих агрессивный стиль вождения и резкие, глубокие нажатия на педаль газа, сухое сцепление будет часто перегреваться, что приведет к быстрому выходу его из строя.

To reduce the negative impact on the clutches in the block oil is poured. The negative effect also appeared due to slippage and a small loss of power at this time, but the node began to withstand more severe loads. This has a positive effect on its durability.

See also: Changing the oil in the gearbox mechanicMost of the leading automakers, including Fiat, BMW, Ford, Mitsubishi, have preselective transmissions in their arsenal. Indicator of prospects is the fact that even in Porsche recognized the relevance of this design, because the company adopts only proven and promising models. Development in this direction continues.

Плюсы и минусы роботизированной коробки передач

Benefits include:

- The design of the nodes is based on the time-tested manual transmissions. This increases the overall reliability of the unit, which is higher than that of the variators.

- The volume occupied in the engine compartment is significantly lower than that of the classic “automata”, respectively, the consumption of oil during operation for this box will be lower than that of counterparts.

- The performance of the clutch, especially the wet type, for “robots” is 25-30% higher.

- Also, the difference between a robotic gearbox and an automatic one lies in the cost of production and repair of this unit, which speaks in favor of “robots” and not “automata” and variators.

- Most modern boxes with robotic controls have the ability to switch steps in manual mode, which is similar to Tiptronic on automatic gearboxes.

- The weight of the robot box is significantly less than automatic transmission. This gives advantages in installations on small-sized cars, where the mass of even a few tens of kilograms plays a significant role.

- Fuel consumption on cars aggregated by “robots” is comparable to the consumption of mechanical gearboxes and is lower than that of other structures, ceteris paribus.

The disadvantages include:

- There are designs with robotic boxes, in which the delay between gear changes reaches two seconds. This applies to electrical switches. With such a ride, the dynamics are lost and there can be discomfort for the driver.

- The use of hydraulic actuators to accelerate switching increases the speed between the switching on of the stage to 0.05 s. However, this design significantly increases the cost of the entire node. Brake fluid used as a working fluid must always be kept under high pressure, which takes some of the power from the engine. Hydraulics becomes more effective in powerful cars or premium cars.

- Cheaper models do not provide adaptive adjustment of automatics to the driving style of the car owner.

- Preselective models are still quite expensive to repair. Although the mechanical part is very reliable, as with simple mechanics, with incomplete firmware ECU and non-ideal clutch design, premature wear of the latter often happens. And all the "attached" equipment of the robot (clutch, computer, actuators) costs a lot of money. Therefore, when buying a used car, it is worth checking the robot with special care and find out the dates of its last service, look at the checks for the work performed.

But most of the positive factors quite easily overlap all the negative aspects. Therefore, in order to enjoy all the “advantages” of robots, it is necessary to choose new designs in which the main drawbacks are minimized or completely eliminated.

Conclusion

The process of the final improvement of the robotic boxes has not yet begun. Engineers tend to make the design more reliable and fast, and by some indicators they succeed. At the same time, cars with “robots” find their fans right now.