The design of modern cars is very different from previous generations. This is due to the fact that the insides of cars of leading auto companies are literally stuffed with progressive advanced systems that work seamlessly with each other. With the probable failures of the individual components of the problems may become global for the functioning of the car as a whole.

Special responsibility lies with the fuel system. A clear supply of the combustible mixture to the cylinders and keeping the operating modes will ensure stable operation of the engine. In such a situation, motorists need to know the signs of a malfunctioning fuel pressure regulator.

Content

- 1 The principle of the RTD

- 2 How the fuel pressure regulator works

- 3 Symptoms of a device failure

- 4 Ways to check for performance

- 5 Installing a new fuel pressure regulator

The principle of the RTD

Before finding out how the device is composed and what it consists of, it is necessary to consider where the fuel pressure regulator is located. Usually this diaphragm valve is mounted on a ramp. The latter is a mandatory element of the internal combustion engine operating on the principle of distributed injection. The task of the ramp is to supply fuel and redistribute it to the injectors.

You can detect the fuel pressure valve in the rail or in the fuel tank. The second option is relevant for the design, which does not provide for the recycling of fuel.

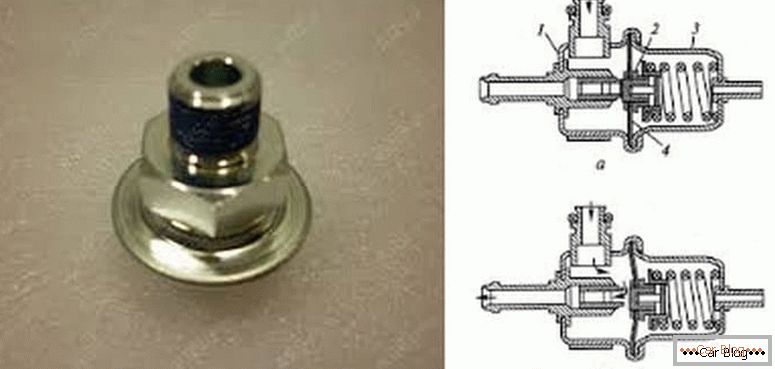

In the classic version, the regulator consists of the following components:

- hard metal case;

- locking cap;

- pipe for the vacuum system;

- flexible membrane;

- working fuel valve.

The internal division of space occurs on the vacuum and fuel plane.

How the fuel pressure regulator works

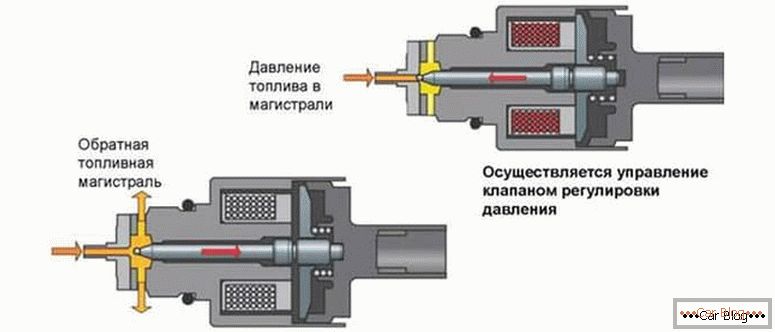

On the one hand, pressure is formed in the regulator due to the spring and this is combined with pressure from the intake manifold. In the opposite direction, the force is created by the fuel pump. When the spring forces and energy are exceeded, a diaphragm valve opens from the intake manifold. In this cycle, the fuel intake is provided in the required volume. Then the pressure from the supplied fuel decreases and the membrane of the pressure regulator closes.

Schematically, the functionality is provided by the design features. Fuel injection occurs in one of the two chambers. In the remaining spring works. The cavities are separated by a membrane opening at a difference in pressure.

It is important to know that some models of modern cars do not have such details as the fuel pressure regulating valve.

In the absence of a valve, its functions are assigned to the electronic special sensor. It measures the voltage in an electric pump that supplies gas to the system. Thanks to this solution, it is possible to fix the pressure at the optimum level, as well as to engage in remote adjustment of the fuel supply. Thus it is possible to directly control the pump.

The system developed on an electrical basis is very accurate when compared with a mechanical counterpart. However, practice shows that the "mechanics" gives more reliability when operating in domestic conditions. The unit is less exposed to negative external influences.

See also: Do-it-yourself injector checkSigns of a device failure

The valve is operated in an intense rhythm. Long loads affect its performance. It is necessary to promptly identify the symptom of a malfunction of the fuel pressure regulator to replace it. Failures and malfunctions are determined in most cases by indirect signs. Such factors include the following phenomena:

- increased fuel consumption;

- deteriorating power characteristics of the engine;

- the power plant loses the stability of operation at idle;

- there are dips or jerks appear during switching speeds;

- the car responds inadequately to the gas pedal.

Often, testing of the fuel pressure regulator begins with determining the quality of the springs. Since the operation of the device, their rigidity has decreased. This phenomenon adversely affects the performance, in particular, the valve opens earlier than the work cycle requires.

The result of a drop in stiffness is the shipment of fuel to the tank in larger quantities than was intended by the designers. At the same time, the pressure in the system decreases, and the engine loses its efficiency and power. If there is a design opportunity, then a weak spring is replaced.

The poor quality of domestic fuels also has a negative effect on the functioning. As a result, the membrane becomes clogged, after which it cannot be closed partially or completely. As a result, the fuel pressure in the system also falls, which leads to negative phenomena.

It is possible to get rid of mechanical blockages by means of cleaning. This is done if the design of the device allows. It should be borne in mind that the repair of the fuel pressure regulator does not always save users. This happens with significant wear or development of the valve as a whole or its individual parts. It is not always possible to restore the operation of the element to the full.

There are cases when RTD is jammed. In this case, the engine simply stalls, and in parallel, the fuel begins to flow from weakly sealed joints. Here repair is not very promising, it remains only a complete replacement of the node with a new one. If this happens, then it is worth changing the filling station or not refueling in advance at questionable gas stations, it is also worth checking the operability of the fuel filter that failed to clean up.

Often there is a partial loss of valve performance. In such a situation, the motor works with jerks, which the driver feels perfectly during the operation of the car. Sometimes they feel and passengers. The timely cleaning of the aisles will be relevant, returning the product to operability..

The electronic device is less susceptible to the quality of gasoline. Also, it is little influenced by mechanical factors. However, it is not without its weaknesses, weaknesses and characteristic vulnerabilities. But if you avoid situations with poor-quality fuel, then you can largely eliminate the loss of efficiency of the regulator.

See also: Setting the carburetor VAZ 2107Ways to check for performance

The condition of the RTD for machines that are equipped with direct fuel injection can be monitored using a manometer, designed for measurements up to 10 atm. The correct connection of the instrument will be in the gap between the outlet fitting and the fuel hose.

Identify discrepancies will succeed when comparing readings with reference values. This will help determine the health of the fuel pressure regulator.

On vazovskih old models experienced drivers pinch or completely disconnect the bypass valve. At this point, you need to pay attention to the force of the jet. The higher it is, the more pressure, respectively. For injection ICEs, this technique loses its relevance, and one can also doubt the high reliability of its results.

When measuring with a manometer at idle speed, the vacuum hose should be folded back. Considered to be optimal fluctuations in the range from 0.3 to 0.7 bar. When there is no such deviation, it is possible to replace the vacuum hose. If a negative result, the pressure will be close to zero, indicating a malfunction of the valve. The latter in this situation requires replacement.

Installing a new fuel pressure regulator

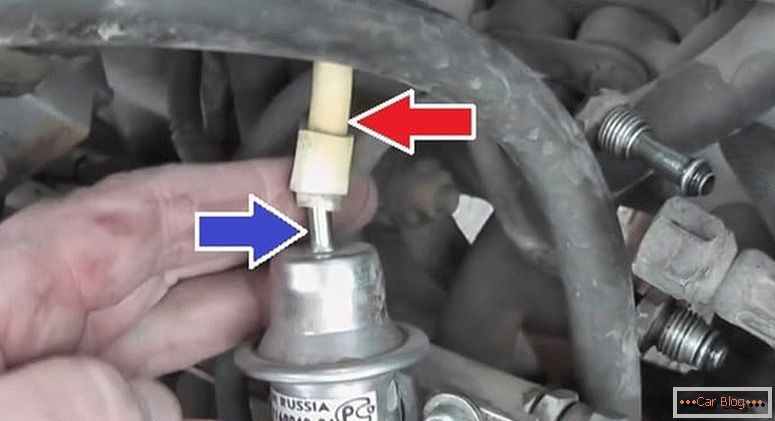

First of all, to control the butt we unscrew the choke plug, equipped with a sealing ring for tightness. Visually monitor the degree of wear of the ring, if necessary, carry out its replacement or tube assembly.

We unscrew an umbrella from the union. Usually, the back of a metal protective cap screwed from a tire helps car mechanics.

We put on the hose with the pressure gauge on the released fitting. For fixing it is necessary to use high-quality clamps.

When diagnosing, you can use a car gauge. Turn the key in the ignition and start the engine at idle. The preferred values are indications in the range of 285-320 kPa or 2.85-3.2 kgf / cm2.

In the next step, we tilt the hose nozzle from the regulator and look at the manometer readings. The increase should reach values of 20–70 kPa more from the starting level. When there is no desired effect, we are obliged to make a replacement.

You need to know how to reduce the pressure in the power system. Have to unscrew the nut securing the fuel tube. Also unscrew a pair of bolts, which the regulator is fixed to the frame.

Carefully remove the regulator nipple from the cavity of the fuel rail to completely get rid of it when dismantling. In advance you need to tilt the fuel tube.

Thus complete dismantling is complete. It remains to put in its place a new part and check its performance by the same method as the previous one (pressure gauge). The assembly is carried out in the reverse order of disassembly.