While the vehicle is moving, a specific hum may occur, which changes the tonality at low revs or noise with a possible rasp at high speed. Such trouble can create a wheel bearing. The performance characteristics laid by the manufacturer should allow the driver not to think about this element of the wheel for a long time.

However, road realities make their correction. The main reason for which the replacement of the rear hub bearing is required is not physical wear, but mechanical deformation. Not all the pits the driver manages to notice on the road, and for the failure of vulnerable parts it is enough to get only one of them.

Content

- 1 Determining the need for replacement

- 2 Replacement procedure

- 3 Installation of the hub

Determining the need for replacement

A constant rumble from the rear wheels should alert the driver, while it is necessary to stop at the nearest place and check the performance of the bearing. The term of its high-quality work is usually about 100 thousand kilometers. While approaching such a parameter, you need to deal with the diagnosis of their condition.

For this work, you will need to perform the following actions:

- would need lock the wheelslocated diagonally to the diagnosed, because you need to check on both sides, because in the cabin it is not always clearly possible to understand where the noise comes from;

- jacked up spin the wheel as much as possible hands until the familiar hum is heard, usually the characteristic problem sound is noticeable almost immediately, because the high-quality bearing works without grinding, crunch and buzz;

- on a dubious wheel, it is worth checking the backlash using a simple procedure, holding the wheel, you need to shake it from yourself and to yourself, and the presence of a noticeable movement is an indication for replacing the bearing.

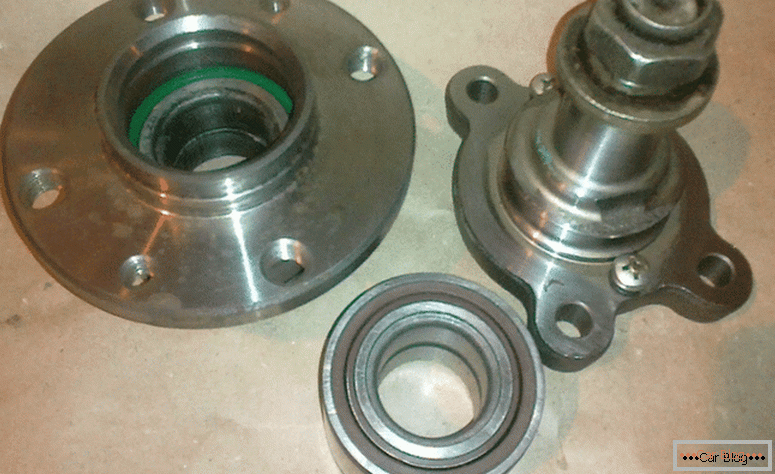

You need to know that most car shops offer a hub assembly with a bearing, but if the bore diameter has no wear or deformation, then you can not change the hub, but buy a separate repair bearing.

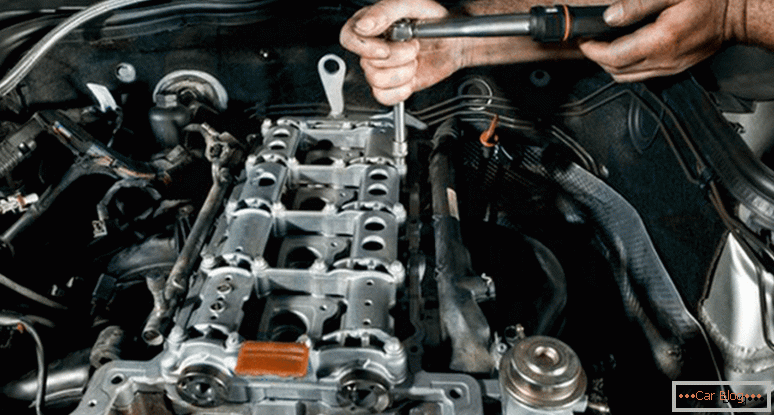

Replacement procedure

Before changing the rear wheel bearing, we block the car with wheel chocks. Weaken the fasteners on the wheel being diagnosed. Also, getting rid of the central cap, let go of the central nut 1-2 turns. Now you can jack up this side.

See also: What oil to fill in the power steeringWe install safety racks under the body and remove the wheel. The seat of the brake drum can be filled with WD-40 to facilitate dismantling. In some cases, use brake fluid or diesel fuel. Before unscrewing the guide bolts, they are usually tapped with a copper hammer so that the “stuck” thread “gives in”.

Dismantle the brake drum. In problematic cases, a special puller is used for such an operation, and for lighter situations, bolts are screwed into the threads intended for them, and a tension is created with their help for removal.

-

- Step 1. Remove the cap

-

- Step 2. Puller unscrew the nut

-

- Step 3. Remove the hub puller

-

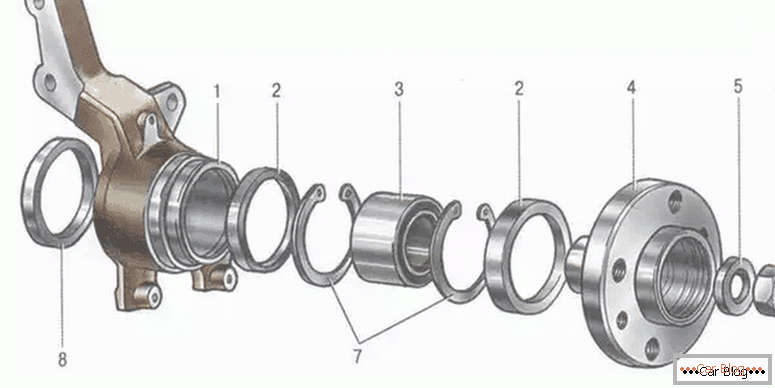

- Step 4. We get the ring and prepare the bearing

-

- Step 5. Removing the bearing

-

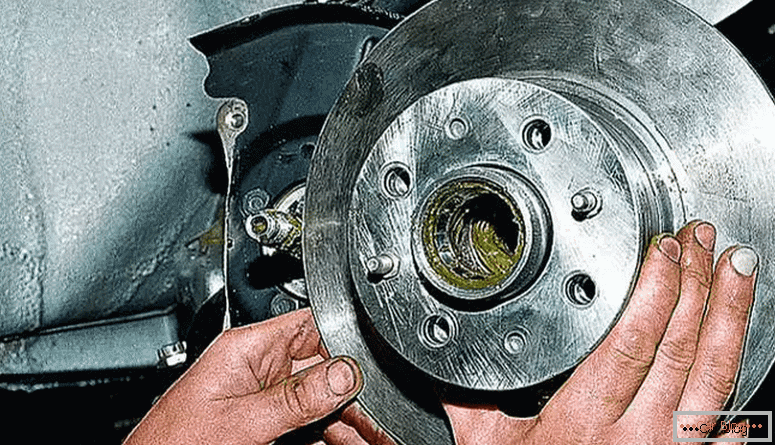

- Step 6. Mount the hub back

-

- Step 7. Zavaltsovyvaem nut

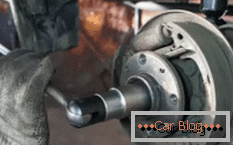

Remove the central nut and stretch the entire hub along the axis. Sometimes there is a bearing cage on the shaft, then using a puller or chisel, dismantle it separately after the hub. The operation is carried out so as not to damage the landing surface.

We conduct an inspection of the axis to identify the turns of the bearing race. If there are any traces (presence of grooves on the bore diameter), then the hub will also have to be changed.

You need to know that the formation of serifs with a chisel or breakdown on a worn surface for a more rigid fit of the bearing sleeve is totally unacceptable! It is necessary to change the worn hub completely in this situation!

The current replacement of the rear wheel bearing can be carried out with the concomitant diagnosis of the remaining elements. It is necessary to simultaneously check the brake cylinder for leaks, and the brake pads are monitored for wear.

Using a removable device, we take out a retaining ring, and if necessary, pour a special cleaning liquid under it to make the bearing easier to press out. It is customary to use one of the three popular methods for dismounting the outer ring from the hub:

- using a hydraulic presswhich is not in every garage;

- reusable puller, its cost is available, and the unit can be used in the future;

- with a hammer or a sledge hammer of 2-3 kg, for this method a special spacer of the appropriate diameter is required.

Hub set on a rigid surface and with a hammer apply a couple of blows on the prepared mandrel. This is done carefully, so as not to damage the landing surface of the mandrel or the rest of the parts with a heavy hammer.

The surface freed from the cage can be cleaned with fine emery paper from possible corrosion spots and then lubricated with oil (it is allowed to use mining). It will facilitate the installation of a new bearing, which must first be assembled with the help of two washers and a bolt. The outer diameter of the washers should be 2-3 mm smaller than the diameter of the bearing.

Before assembly, grease can be added to a double-row separator. With the help of a hammer, preferably with a copper or bronze finish, lightly tapping on the opposite sides of the "plant" bearing.

You need to know that the bearings are made of high-alloy steel, which under strong dynamic loads (sharp blows) can crumble, so it is recommended to use “soft” copper or bronze spacer to avoid damaging the clips.

If at the initial stage the approach turns out to be tight, then there is probably a bias, so it is worth equalizing with light strokes, rather than applying unnecessary effort. When the new holder comes in half, the old one can be used as a spacer. We continue until until the groove for the locking ring. Fix the bearing ring.

Mounting hub

We get rid of the tightening device from a bolt and two washers. Now you can return to its place the hub. Be sure to install a new central nut, pre-lubricating the thread with a “lithol” or other lubricant.

Install the brake drum fasteners. We put the wheel and fix it with mounting bolts. We turn the wheel "by hand" and listen to extraneous noise. The absence of hum or gnash, as well as free rotation indicates the correctness of the assembly.

We lower the wheel with a jack, and only after that we carry out the final tightening of the central nut. It is recommended to use a torque wrench for this operation. The tension value should be close to 20 kg / m. This value is quite large, so without a special key you will need to increase the key length. Now you can tighten the hook and tighten the mounting bolts on the wheel to the required effort.