The overhaul of the engine violates the established unity of the “used” elements. Boring the cylinder block and installing new elements of the piston group will change the output characteristics of the car. Often the power is reduced almost twice from the set by the designers.

In order to restore the original characteristics, it is necessary for the power plant to pass the break-in mode. Such an engine run-in after overhaul is usually performed within a specified operating time or mileage.

Content

- 1 Engine work after overhaul

- 2 The purpose of running the car

- 3 Recommendations for the process

- 4 Preparation for the first start-up after repair

- 5 The first start of the engine for running

- 6 Running in

Engine work after overhaul

On average, engine running in modern cars ranges from 2 to 3 thousand kilometers. Full lapping for such a period does not occur, but it becomes possible to operate the machine in more aggressive modes, with increased load.

At its operating parameters, the car goes to 10-15 thousand kilometers.

When the engine is running in after an overhaul, during rubbing, the heating of rubbing elements increases. In this regard, undesirable power loads on the motor, and it is recommended not to raise the speed above 60% of their maximum level during standard operation.

The power plant, after improper running, can lose in power up to 70% of the calculated parameter.

With proper operation of the car all the parameters quickly return to the planned.

The purpose of running the car

The machined surface of the engine cylinders and the newly installed repair units has protrusions and depressions, sometimes pointed traces from the work of the tool, which have not been removed by honing. The task of running is to smooth out such defects. Due to this, friction is reduced and the load on all working units is reduced.

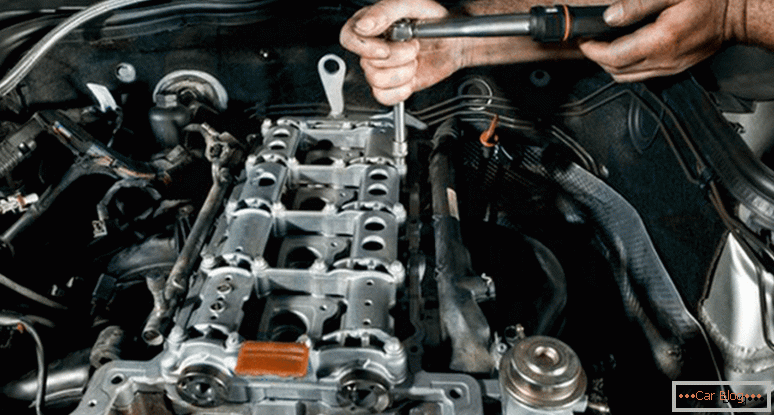

Engine assembly for running

The opinion that running in a new engine because of the installation of new nodes in the motor does not make sense is wrong.

Each new item has residual microroughness, which will be removed in the process of grinding. The time required for the entire process depends on the size of such irregularities. After a complete lapping, all the elements: cylinders, piston rings, pistons get a new surface finish on the contacting planes.

Recommendations for the process

There are rules under which the process will lead to the desired results:

- The oil used during running should be on the list recommended by the manufacturer.

- Oil supply should be carried out no later than 5 seconds after starting the engine in all the necessary components to avoid dry friction.

- When idling the engine, the oil pressure in the system should be in the range from 0.5 to 1 atmosphere.

- It is necessary to check the sensors measuring equipment for performance.

Before the running-in process, a small preliminary work is also required:

- Washing and purging of the interculor is carried out, if necessary.

- Changing the air filter or oil from an oil bath.

- Oil change and installation of new oil filters.

- Changing fuel filters.

- Checks the level of coolant and the presence of fuel in the tank.

- The fuel pump is being adjusted and the injectors are working as recommended by the manufacturer.

- Removes air from the fuel system.

Preparing for the first start after repair

The crucial moment after the assembly of the repaired motor is its first launch. If you do it ineptly, sometimes even piston rings can break. To perform the first start-up, you must fully charge the battery. The starter must be in good working condition.

Incorrect car break-in

Unprocessed parts will take a lot of power by increasing the friction forces between untreated nodes.

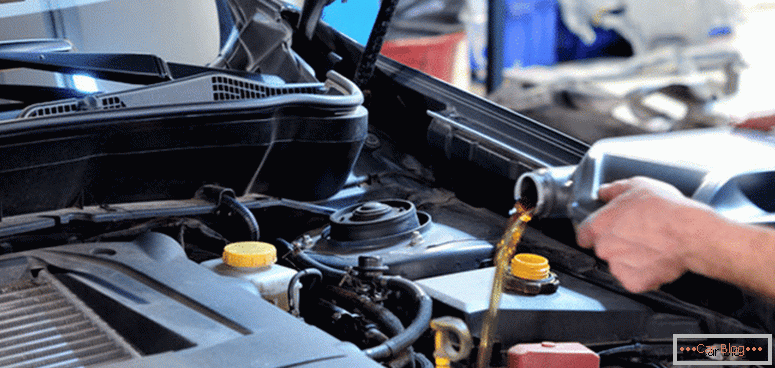

Fill the quality engine oil proven company. Oil consumption during the engine run-in can be approximately 1 l for the first 2-3 thousand mileage. This parameter is allowed by experts.

When pouring oil you need to know that it is not immediately distributed to all nodes. Therefore, you can measure the desired volume, so as not to make a mistake, and pour everything into the engine. It is not recommended to wet the oil filter in advance, as this process does not contribute to the rapid distribution of the liquid throughout the system. Rather, on the contrary, an airlock is formed, degrading the engine.

It would be preferable to force oil through the hole in which the pressure sensor is mounted. At home, for this operation, you can use the tire pump, removing the non-return valve from it and mounting the threaded adapter to the end of the hoses.

Topping up oil during running

When there is no manual fuel pumping on the pump, we perform the established sequence of actions: tightly close the neck of the fuel tank, remove the inlet hose from the pump, pump up a little pressure into the fuel system with air. After that, quickly return the hose to the pump fitting and connect them.

You need to know that excessive pressure in the fuel system can inflate the vehicle tank permanently.

Due to pressure equalization, a certain amount of fuel will be poured into the pump. Set the air damper in the desired position. And getting ready to start the engine.

See also: How to adjust the throttle position sensorThe first start of the engine for running

Starting the rotation of the starter, you must ensure that there is oil pressure in the line. To do this, connect a pressure gauge or use the tips of the indicators on the panel.

The first start after overhaul

It is urgent to turn off the engine if there is no pressure in the first three or four seconds.

It will be necessary to add oil again to the required level.

When the oil pressure is established on the working parameters of the order of 3-4 kg / cm2, you need to warm up the engine idle (700-800 rpm). The temperature should be set at 83-93 degrees. At this time of running in, you need to carefully consider the appearance of various obscure noises, visible leaks that may appear at the initial stage.

A little smoke under the hood is a normal phenomenon for the operation of a car after an overhaul.

This oil, which has got on the external part of the motor, after the temperature rise of the power plant burns out a little and smokes.

Increasing the coolant temperature usually goes along with decreasing oil pressure. The level of oil pressure should not fall below 0.4-0.8 kg / cm2. It should be understood that a complete drop in oil indicates errors made during the assembly of the engine.

Running in

After a short running-in at idle, the engine is jammed. It should be left alone before the temperature drops to 30-40 degrees. Then start again, wait and silence again. About 15-20 such preliminary running cycles are carried out.

Sparing driving mode

After that, you can gradually increase the speed:

- 3 min - 1000 rpm;

- 4 min - 1500 rpm;

- 5 min - 2000 rpm

All this time we are monitoring noises and leaks.

After idle run, you can carry out this procedure with a small load on the go.

During the drive you do not need to exceed the speed limit of more than 60-70 km / h. The first 300 km of smoke may appear from the exhaust pipe, especially when installing new rings. Regularly required to adjust the setting of idle speed.

After a break-in mode of 3,000 km, the speed can be increased to 90 km / h. At this initial stage of running can be considered complete. But up to 10-15 thousand km it is desirable not to overload the car with aggressive regimes.