In addition to the automatic and mechanical boxes, there are other types of equally used in cars. Such is the robotic gearbox. In common people it is often called the box-robot. This device combines mechanical and automatic functions under one housing. In particular, manual transmission and clutch disengagement functions are automated at Manual transmission.

Thus, this manual box, having received “information” from the driver, and, depending on driving conditions, begins to be automated controlled by a special electronic unit. This gearbox has incorporated the best performance of automatic and manual transmissions, including economical fuel consumption, ease of operation and reliability in operation.

In addition, the robotic box price is more affordable than the automatic counterpart. Recently, such a box is very popular not only among manufacturers, but also among car drivers.

Design Manual transmission

This box is also called a semi-automatic. And although robotic gearboxes are different in their device, you can select their main elements. This is the presence of a manual transmission, clutch, drive to it, the gear itself and the control unit. The basis of the device Manual transmission is a manual gearbox.

The drive at the gearbox is hydraulic or electric. The electric drive is based on the work of servomechanisms. And in the hydraulic drive the leading role is played by hydraulic cylinders. In the first case, we have no energy consumption and lower speed. In the second case, it is necessary to maintain a given amount of pressure, therefore, the energy consumption increases.

Robotic gearbox with electric drive is used in low-cost models of cars, and with hydraulic drive - in expensive cars and even sports cars. And it is quite natural. Indeed, when using a hydraulic drive, a high speed gearshift is noticed. The control system of the Manual transmission is electronic and controls sensors and other devices.

Recommended article: Tiptronic: what is it?Implementation of the work Manual transmission

Ferrari California has a seven-speed robotic box “F1 DCT”

In the car, the gearshift lever is located next to the manual transmission lever, but shifting is done back and forth. And in sports cars, the speed lever is replaced by two pedals. When you press one of them, the speed increases, and when you press the other, it decreases.

The principle of operation of a robotic gearbox is not complicated, it combines mechanics and automation. As soon as the gear shift and the accelerator pedal pressure have occurred, a signal is transmitted to the control unit. The gearbox begins to provide information about the required speed and current speed. In turn, the block selects the optimal value of speed and the right moment when it needs to be switched.

Due to this, synchronous operation of all elements of the device occurs. It is the system unit that controls the work of hydromechanics, namely, closes and opens the clutch. This whole process is invisible to the driver, since all the processes coincide with the movement of the gearshift knob.

Since the electronics quickly reacts to the driver's actions and road conditions, the clutch is carried out automatically without his participation. To park, choose reverse or neutral transmission, you need to press both pedals, and then select the desired position of the handle according to the selected option.

Coupling in a car equipped with manual transmission is basically necessary to start the movement of the vehicle. In order to achieve a rapid change in speed, it is necessary to stop pressing the gas pedal and set the speed control knob to the desired position.

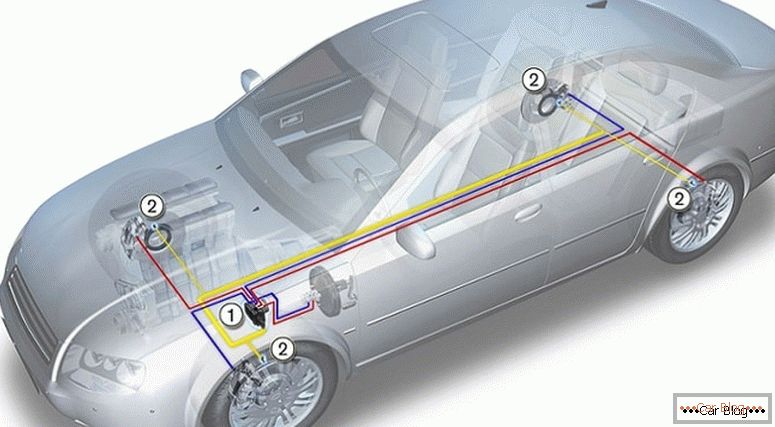

Device and scheme Manual transmission

Manual transmission consists of certain components. Conventionally, the scheme of the robotic gearbox is as follows. Conventional manual transmission, actuators, control system and external sensors. It is worth noting that the work Manual transmission is not at all like the work of the automatic box. It can be compared more with the work of mechanics with automation elements.

Recommended article: Fuel pump (fuel pump) VAZ 2109 (carburetor) and its replacement

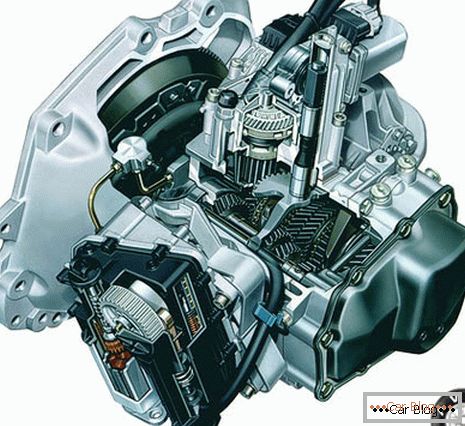

Let us consider the device of a robotic gearbox. She has two leading shaft, one is in the cavity of the other. The outer shaft has gears for even gears, and the inner shaft has gears for even gears. Both shafts have a grip. Actuators are electric and hydraulic actuators, discussed in detail above.

The main element of the Manual transmission is a control unit equipped with a powerful processor. External sensors are connected to it through special ports. Also, most often cars are equipped with on-board computers, which are also connected to the control system. The control system has a memory and certain work algorithms that successfully process the signals arriving at them and control the gearbox and gear shift.

And here is a video on how to properly use the robot box: