By purchasing an imported car, many cannot rejoice in its comfortable operation. Today, the vehicle is comparable to a computer, as it is stuffed with a variety of electronics designed for comfort and reduced risk of accidents. Safety equipment includes an interesting option such as ABS (Antilock Brake System) - Anti-lock Brakes. Although it has long been established in Russia and has become the standard of equipment for all new cars, but there are still those who happened to face it for the first time.

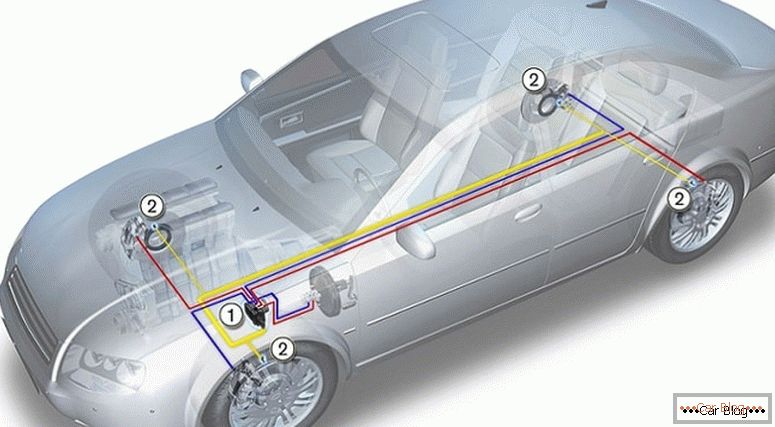

Предназначение АБС – при экстренном торможении не допускать блокировки всех четырех колес. Что позволяет транспортному средству сохранить устойчивость при движении, а на покрытиях с низким коэффициентом сцепления (гравий, мокрый асфальт, снег, лед) сократить тормозной путь. Помимо этого, АБС позволяет машине даже при полностью выжатой педали тормоза оставаться управляемой и не идти в занос. Этот многокомпонентный блок, соединен с системой тормозов, находится он под капотом между главным тормозным цилиндром и тормозными цилиндрами суппортов. Состоит система АБС из основного гидравлического блока модуляции давления жидкости, системы датчиков, отслеживающих частоту вращения и расположения колес, and компьютера, в котором обрабатывается информация с датчиков и отправляется сигналами на основной блок.

ABS device

Content

- 1 The principle of the ABS

- 2 Danger of failure of the ABS

- 3 Symptoms of an ABS malfunction

- 4 The main causes of ABS failure

- 5 Diagnostics of malfunctions of ABS

- 6 How to check ABS sensors - visual inspection

The principle of the ABS

The ABS sensor system monitors the speed of rotation of the wheels and the car itself. In time of strong pressure on the brake pedal, the sensors determine that the car goes skidding and sends a signal to the block to reduce the braking force, after the fluid pressure in the brake line drops and the wheels unlock. Moreover, if the brake pads are not unclenched, then the process repeats until it returns to normal. In short, the whole work of the ABS is reduced to a cycle of inhibition - analysis - disinhibition.

The system is triggered instantly, even before the wheel locks, a signal about this goes to the dashboard and characteristic jolts appear in the brake pedal. When the inscription on the dashboard is permanent, it indicates a malfunction of the ABS. Remember that no matter how active the ABS in terms of security, the main driver is still the driver. The presence of ABS in the car creates an illusion of safety in many people, but in practice, if the system takes control over the turns and directional stability, it does not in any way shorten the braking distance.

Anti-lock system

With ABS it is not easy to calculate the stopping distance and predict where the vehicle will stop.

Danger of failure of the ABS

Although modern ABSs have a fairly high reliability and can work for a long time, but, like any other systems, they can fail. This happens extremely rarely, because the electronic components are protected by special relays and fuses. If the failure still occurred, it does not affect the performance of the entire brake system. The ABS module simply turns off, and the brake system begins to work normally. You should not ignore the violation, as you can overestimate your capabilities or simply forget during an emergency braking. At the first signs of a malfunction, you should not immediately go to the service station, you can try to solve the problem yourself - by diagnosing ABS.

Symptoms of an ABS malfunction

The first sign of a system failure is an indicator on the dashboard. When the sensor does not go out within 6–10 seconds or turns on while driving, it means that the system is faulty and does not function properly. It is important to know that the failure of the module can not be detected only in the stationary position of the vehicle, some failures can be recognized only when driving at speeds of 25 km / h. Before you start looking for problems, remember if you have changed tires on wheels. So how often, in order to save a lot of people, install studded tires in the winter period only on driving wheels. And since the diameter increases slightly, the wheels begin to rotate at different speeds, which causes the system to flash. In addition, there are cases when the sensor is lit during slippage, but, as a rule, in both cases the indicator does not light up briefly or flickers from time to time.

ABS system

The main causes of ABS failure

There can be quite a lot of problems with the anti-lock system; there are 4 common causes of a malfunction in the ABS:

- There are breaks in the wire of the abs sensor or a malfunction of the controller unit. In this case, an error is displayed, signals about a change in angular velocity cease to be given, and the entire system is turned off.

- The failure of the wheel sensors. When the ABS after switching on passes self-diagnosis and finds an error, but continues to work. The reason is often in the oxidation of contacts, poor connection to the power supply of the system, or the closure of wheel sensors to ground.

- Different tire pressure and tread patterns. As a rule, information about the angular velocity in this case comes from an additional device. When one of the wheels is deflated or the tread of one wheel is coarser than on the rest, it starts to brake. In addition, the same effect can be observed if you install tires with varying degrees of wear.

- Mechanical damage to the elements - separators of wheel bearings, grilles, broken wires near the sensor, wear of the wheel bearings, the presence of backlash and a broken wheel wheel rotor. With these failures, the ABS does not start at all. This may also include the failure of the ABS pump.

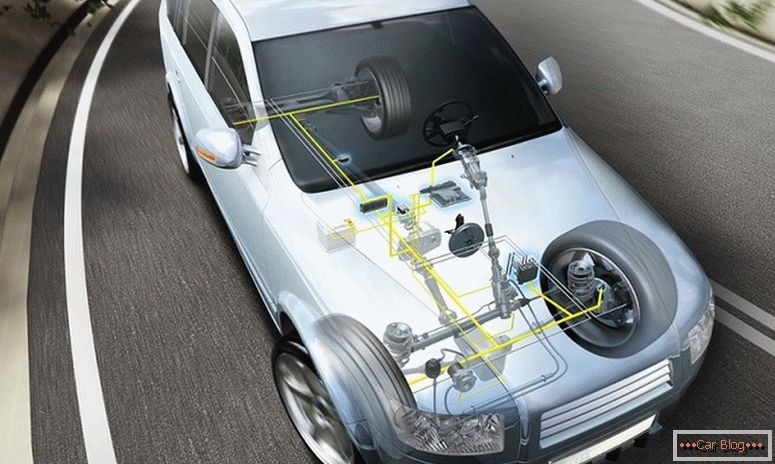

All of the above problems can be solved on their own, sometimes it is enough to identify the problem and repair some blocks of the ABS, than to make a complete costly replacement of equipment. The most vulnerable in the ABS scheme are wheel sensors, which are located next to rotating hubs and axles. The location of the sensors is poor, as the dirt and increased play in the hub bearings can provoke a malfunction in their work, thereby reducing all the work of the anti-lock braking system to zero.

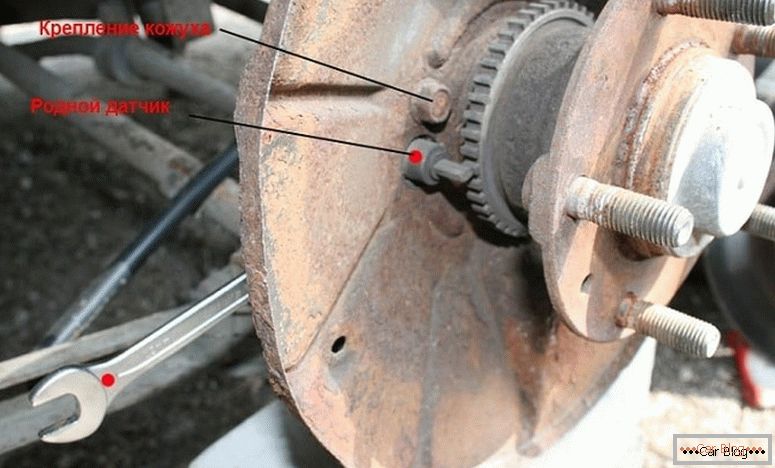

ABS sensor on the wheel of the car

Not infrequently, the voltage between the battery terminals affects the performance of the unit. If the voltage is reduced to 10.5V or lower, then the system can turn off abruptly itself through the safety unit. Since the safety relay always reacts to unacceptable surges and voltage fluctuations in the network of the vehicle. It is possible to exclude such situations, if the electrical connectors are not disconnected with the ignition on and the engine running. It is necessary to constantly monitor the contacts of the connections on the generator and not to start the engine using the “lightening” method.

Fault Diagnosis ABS

The most expensive part when replacing is the control unit, but as mentioned above, it is protected by a relay, which reduces the risk of its failure. The only thing that can knock him out of action is the temperature difference, which we also described above. Therefore, the central part of the system can be safely removed or transferred to the last item of the check.

Diagnosis of ABS with their own hands begins with the front wheels:

- Remove the sensor.

- We clean it from dirt and accumulated sediments with kerosene or white spirit.

- We inspect the teeth on the wheel hub. It is from them that the sensor reads speed turns, when the teeth are clogged with dirt, respectively, the data is read incorrectly, which leads to the suspension of the ABS.

- We remove the blockages from them, and we do the same with the reverse gear sensor.

- After you need to check the electrical resistance, which is written in the factory reference book of the car. When it is impossible to find out the exact resistance, contact the store and ask the seller for resistance on your vehicle model.

- When everything is in order with the sensors, we switch the multimeter to the voltmeter mode, which measures the alternating voltage.

- Jack up the car and spin the wheel and measure the voltage in the sensor winding as it rotates. You can also find out the normal voltage unit from the manual of your car.

- Go to the bearings. Worn wheel hub is the most common cause of system malfunction. It is necessary to clean all the same with kerosene from dirt and check them with the help of staggering. If they are faulty, it will come to light immediately. It is necessary to replace worn-out elements and test the sensor operation with a multimeter.

Repair of the ABS unit

When the inspection with cleaning the sensor parts did not produce results, then perhaps the problem lies in the protection relay, which, as we know, protects the electronic circuits from voltage fluctuations in the vehicle electrical system. It is easy to find a protective relay if you have a machine circuit in your hands. The walls of the relay are mostly aluminum, and the cover is plastic. Under the cover there are two or one fuse that can simply burn out, then they need to be replaced. When it is not in it, then, perhaps, pressure drops have disabled the protective relay itself. To diagnose it again, take the tester and go through the points:

- Disconnect the connector from the electrical unit, which is located near the relay. The standard connector has 25 pins.

- Put the tester in the position of a voltmeter.

- We connect its probes to the first and second pins of the block. It is easy to confuse them, as they are numbered.

- When the ignition lock is on, we measure the twenty-volt voltage of the onboard network.

- If there is no voltage, then we look at the integrity of the fuses and check with minus connector number two for a connection to the mass of the machine.

When this part of the problem is not revealed, we proceed to check the relay itself. It is necessary to remove the protective relay from the car and connect the two wires from the battery terminals to the relay terminals labeled 5 and 6. The working relay when connected to 12 volts will produce clicks, when there are none, you need to replace it.

ABS sensor replacement

How to check ABS sensors - visual inspection

Alternatively, the ABS system can be tested using scanner ELM-327. The induction type sensor is an induction coil, working in tandem with a serrated metal disk, located above the pulse rotor connected to the drive shaft or wheel hub. The sensor can be broken tester, soldering iron, and pin for repair, but first it is worth checking the sensor clean, look for dirt, and if there are any, eliminate it. Next, go to the measurement of the resistance voltage in the node.

Around the pole core there is a winding connected with a magnet. This proximity allows the magnetic field to pass freely to the inductor. And since rotor rotations and interdental hollows change, the magnetic flux going through the winding core changes. Such changes create an alternating voltage, the level of which must be measured. The frequency of the voltage and amplitude depend on the number of wheel revolutions.

ABS light bulbs

Pins are mounted on the connectors, and the resistance of the abs sensor is measured by a tester. When measuring rate of resistance in the range of 800-1200 OHM, but it is better to look at the passport and check with a valid unit. When the network increases to infinity - a network breakdown has occurred, and if the resistance is zero, a short circuit in the sensor circuit has occurred. To conduct a complete diagnosis of the sensors, it is necessary to ring the tester all the wiring of the device. When everything is normal the readings will be as follows:

- insulation resistance level - more 20K ohm;

- leg - abs front front right sensor 7-25 ohms;

- leg - ABS sensor rear right 6-24 ohms.

When a breakdown is detected during the inspection of the sensor, then it is pointless to repair it. If the malfunction is not found, then it is not recommended to interfere with the operation of the central unit. Specialists will review the trouble codes previously stored in the device and take appropriate action.