Perhaps you have ever paid attention to cars with nameplates or stickers "turbo". Outwardly, they are no different from their "atmospheric" counterparts, the only difference is in the presence of turbocharging under the hood. We will try to give a clear explanation of what a turbocharger is, what it is for and how it works.

Content

- 1 Theoretical aspects

- 2 What are the types of turbocharging

- 3 mechanical boost

- 4 Gas turbine supercharging

- 5 Pros and cons of turbocharging

Theoretical aspects

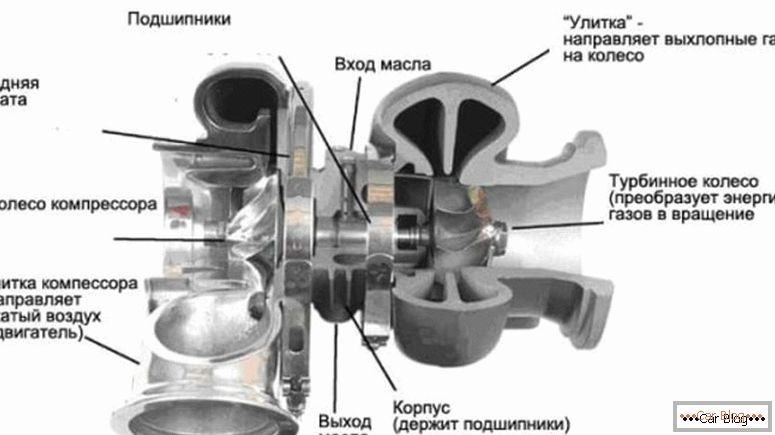

Approximate view of a gas turbine

Since its introduction, cars, through the efforts of their creators, have undergone modernization and most of all in matters of engine power. Since this parameter is directly related to the working volume of the motor as well as the quality of the supplied air-fuel mixture, there are two ways to increase the power - either to increase the volume of the unit (in the modern mass automotive industry, this method is not very popular), or somehow inject into cylinders more air. The first method is not popular for obvious reasons - along with an increase in the volume of the cylinders, the fuel consumption will also increase, moreover, the unit itself will add significantly in size and mass, which is also not always acceptable. Therefore, automotive engineers found a way to increase the air supply to the cylinders.

What are the types of turbocharger

There are several ways to force more air into the engine:

- resonant pressurization - is realized without a supercharger due to the kinetic energy of air in the intake manifolds;

- mechanical boost - air supply is increased due to the use of a mechanical compressor, which, in turn, is driven by a car engine;

- gas turbine supercharging - the turbine drives the flow of exhaust gases.

In the first case, the boost occurs only due to the particular shape and size of the intake manifolds without the use of any blowers. Therefore, we will not describe it in this material, but will dwell in more detail on two other options that, in our opinion, deserve special attention.

Mechanical boost

Some modern cars are still equipped with compressors.

Mechanical boost — способ увеличения подачи воздуха в двигатель посредством использования компрессора. Принцип работы компрессора выглядит следующим образом: когда двигатель начинает работать, его коленвал приводит в действие весь механизм. То есть механический наддув работает с первых моментов запуска мотора автомобиля.

The undoubted advantage of such a system can be called the fact that the air is forcibly forced into the cylinders at any engine speed (even the lowest) and the pressure increases accordingly with an increase in the crankshaft speed. Therefore, cars with mechanical compressors are not familiar with such a thing as “turbo-lag”. But such a device has its negative sides. The fact is that a car's motor consumes a certain part of its power to bring a compressor into motion, which ultimately reduces its efficiency. In addition, to install a mechanical pressurization need more space in the engine compartment. Also, such a device creates an increased noise level.

See also: How to adjust the throttle position sensorAir injection into the engine using a compressor began to be used in the automotive industry much earlier than the use of a gas turbine mechanism. Nevertheless, in spite of some obsolescence, such devices can still be found on modern cars (a striking example is the company Mercedes-Benz, on the newly-manufactured machines of which the Kompressor nameplates still adorn).

Gas turbine boost

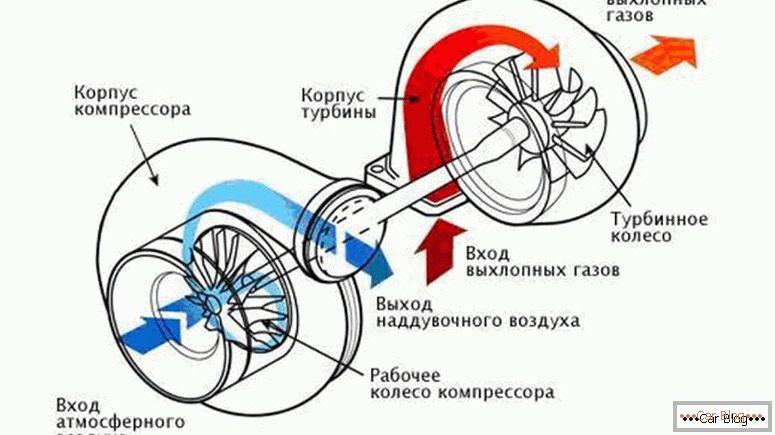

Most modern cars are equipped with turbocharged gas turbine systems. The principle of operation of the turbine is similar to compressor supercharging, the only difference is that the turbine is driven by the flow of exhaust gases of the car, not the engine crankshaft. On sensations, the inclusion of the turbine, some drivers compared with the "kick". The gas turbine pressurization mechanism is a device of two impellers rigidly interconnected by a shaft. Each impeller is enclosed in a casing, the so-called snail.

Gas turbine device

The device of the turbine is quite simple and consists of:

- two impellers;

- two snails, inside which the impellers rotate;

- the shaft connecting the impeller;

- sliding bearings - two support and one thrust;

- a bypass valve that is used to relieve excess pressure.

The principle of operation of the turbocharger is quite simple. Exhaust gases from the exhaust manifold enter the first cochlea and rotate its impeller. Through the connecting shaft, the rotation is transmitted to the second impeller, which injects pressure in the second volute.

Pros and cons of turbocharging

The main advantage of turbocharging is to increase the power of the engine without a significant increase in fuel consumption. To explain this phenomenon, you need to understand how the turbocharger works: the turbine is driven only by the energy of the exhaust gases, and not by the power of the car's engine. But it is necessary to distinguish such concepts as the general and specific profitability of the motor. In other words, a turbocharged engine will have a greater fuel consumption than an atmospheric unit of similar volume. This is because the increased volume of air entering the cylinders allows more fuel to burn. However, the turbocharged unit has less fuel consumed per unit of power. For example, if you take two 1.4-liter engines with a turbine and an atmospheric 1.8-liter, both with a power of 130 hp, then 1.4 will be more economical, due to greater efficiency.

See also: How to check engine compressionAs for the environmental friendliness of turbo engines: although among the local car enthusiasts the “environmental awareness” is not so well developed, one should not forget that the turbocharged engines cause less damage to the environment. This is because the temperature in the combustion chamber of a turbocharged engine is somewhat lower, therefore the formation of nitric oxide is reduced, and the fuel is burned more completely.

The principle of operation of the gas turbine

However, it was not without flaws. The first thing you should know - the turbine requires a careful attitude. While the motor is wound on the bearings, the oil is fed under pressure. As soon as the motor is plugged, the oil to the bearings stops. If the engine was operated under heavy loads, the pressurization system may overheat and fail. In order to prevent overheating, before shutting down the turbocharged engine, it should be allowed to run for a few minutes at idle. Many modern cars are equipped from the factory with specially designed devices - turbo-timers.

There is one more important moment - at low engine speeds the efficiency of the turbine is very low. You should also mention the effect of turbo mode - the turbine responds to pressing the accelerator pedal with some delay. Turbocharging can only work effectively in a narrow range of engine speeds, in addition, the size of the turbine itself is of great importance. To increase the productivity of this system, many automakers install on their cars two turbines of different sizes or a pair of identical turbines. Turbines of different sizes can significantly expand the range of efficient operation of the turbocharger - after the first turbine begins to lose productivity, the second one enters. Two identical turbines make it possible to increase productivity, improve accelerating dynamics and reduce the effect of turbo yams. To reduce this effect, automakers have resorted to such tricks as reducing the mass of moving parts of the turbine. Thanks to this turbine, it takes less time to unwind.