During the winter cold there are cases when the battery loses its effectiveness. As a rule, in such cases, motorists resort to the tried and tested method - to light a car. However, this effective method sometimes does not bring the desired result and the fault is poor-quality wires for lighting. There are very few really good products in the stores, and the owners of cars are forced to buy not the best product.

We will understand how to choose wires for lighting

Board number 1. The best are the wires of copper. It is clear that pure copper is not sold, but in the alloy used it should be as much as possible.

Tip number 2. Wire cross section should be optimal. The fact is that the cross section is directly related to the strength of the transmitted current. If you choose too thin, the current will not be enough. For passenger vehicles suitable wire section of about 10 mm.

The appearance of high-quality wires for lighting and their components

Tip number 3. Do not get involved in the length of the wires. For comfortable lighting, 3–4 meters of wire will suffice, otherwise the resistance will be too great.

Tip # 4. Isolation of wires is very important. It must withstand large temperature fluctuations, while not crack and not break.

Tip number 5. The so-called "crocodiles" (fasteners wires to the terminals) should have good clamps. If the wire falls off and hits a metal part during a cigarette, a short circuit can occur with serious consequences.

Self-production of wires for lighting

Poor-quality wires for lighting are equated to their absence, since they will not transfer the required current. You can spend a lot of time searching for wires with the right characteristics, but it's far from a fact that in the end a thing will be found. Some motorists prefer not to rely on the honesty of the sellers and make a means to light their own. For some, it may seem that the manufacture of such wires will require special skills, but in fact almost any person will cope with the work. So, go to the store.

-

- We fix the wire on the crocodile

-

- Wrap the wire around the crocodile's handle and solder it

-

- Done!

First you need to purchase the wire directly. It is best to choose a cross section of at least 10 mm, thanks to which the wires for lighting a car will be able to withstand high loads. It is also extremely important to choose the right insulation. Ideally, the winding should be made of cold-resistant rubber (labeled as CL) or silicone. If this factor is not given due attention, the isolation will simply crack in the winter and money will be wasted.

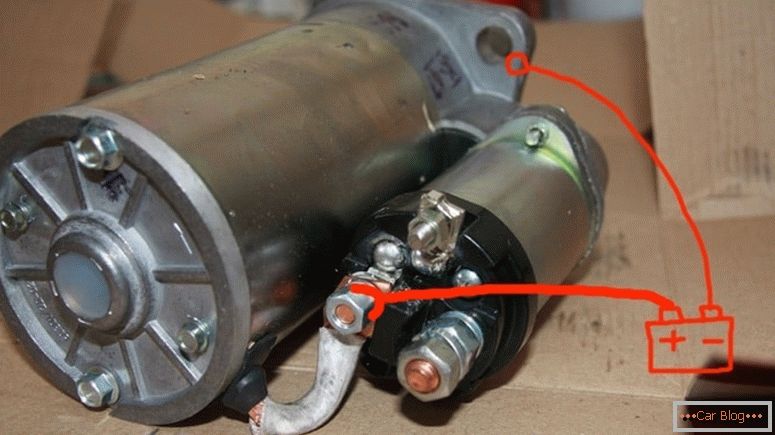

The next important step is the manufacture of clips for the battery terminals. You should not get too small "crocodiles", as they will not be able to withstand the desired amperage. It is better to buy simple clips and improve them a little by installing copper plates (the copper insert will come into contact with the terminals). Copper should be one and a half to two millimeters thick, and you can bend it with ordinary pliers. Giving the plates the desired shape, you need to fasten them on the clamps. The best solution would be steel screws or rivets. For greater efficiency, "crocodiles" need both clamping parts to connect a special wire "AMG".

AMG wire. In our photo example, it was not used above, since crocodiles are completely made of metal and no additional conductor is needed.

The last stage remains - soldering wires and clips. Pre-wire and soldered part of the "crocodile" need to be covered with tin (pass), then with the help of a powerful soldering iron to make the connection. For best quality, it is important to use neutral flux and refractory solder. If we take into account all these recommendations, the wires for lighting your own hands can be made very durable and reliable.