>

It would seem that the limits of improving the tool for performing trivial and routine tasks (drilling, tightening / unscrewing screws, bolts, nailing) have long been reached. It turns out that even the simplest instrument of action is subject to the influence of pervasive technical progress. There is no exception and a wrench, the existence of which many representatives of the strong half of humanity do not even guess. The best wrenches are professional fixtures that can easily cope with the most uncomfortable bolting. About what are the wrenches, what criteria should be considered when choosing them, and will be discussed in this review.

Wrench greatly speeds up and eases work.

Gaikovurt: appointment, functions

This manual or mechanical tool is used to work with various threaded fasteners:

- bolts / nuts;

- anchors;

- front dowels;

- wood grouse;

- anchor screws;

- threaded rods.

Common in these fasteners is the presence of a hex (in rare cases - square) heads. On sale you can find electric, pneumatic, manual and other types of these devices, designed to solve various problems.

In addition to the actual twisting / twisting, wrenches are able to perform a number of other operations:

- tighten the fasteners with a given torque (this is important, for example, in the field of car repairs, where it is often necessary to tighten the bolts with a certain force);

- turning away the nuts with the use of shock-pulse action, which is necessary when disconnecting the old fasteners without their destruction

How did you set up?

Outwardly, this tool can be completely confused with a drill or screwdriver, since its design consists of the same two essential elements: the barrel and the handle.

Inside it are hidden engine, gearbox, pressure mechanism (usually in the form of springs) and clip. The principle of operation in general form can be described as follows: when the device is turned on, the engine transmits torque to the gearbox, which acts on the clamp. The vast majority of models can operate in direct and reverse modes.

The process itself resembles the action of a percussion instrument, but with a slight improvement: the impact force directed to the cartridge is carried out with a simultaneous pivoting (in one of two directions), which ensures the formation of the torque force required to tighten / unscrew the fasteners. At the same time, the design of the wrench prevents vibrations that would be transmitted to the person working with the tool.

The diameter of the holes of the clamping chucks is usually fixed in size: half an inch, 3/4 and one inch. As a rule, a half-inch tool is used for solving household tasks, the other options are considered professional, most often used in the field of construction and car repairs.

Wrench Selection Criteria

Regardless of the purpose for which this tool is acquired, when solving a problem, how to choose a wrench with optimal characteristics, it is necessary to take into account the following important criteria:

- Torque is one of the most important parameters. With the wrong selection, you either cannot perform the required operation (if the torque is not enough to loosen the connection), or you risk damaging the fasteners if the applied force is too large. For example, for the installation of a small greenhouse will be enough efforts of about 200 Nm, and when repairing the railroad tracks will require a tool with a torque of up to 1000 Nm.

- The scope of its application, as well as uptime, depend on the power of the wrench. To perform simple household tasks suitable tool, issuing 300 watts, for professional use it is better to purchase models with a capacity of 1200 watts and above.

- Speed is the third most important parameter. High-speed devices (about 3000 revolutions per minute) are relevant when performing general construction works, in car repairs, where speed of operations is important. For domestic purposes, 100 rpm is sufficient.

- The type of drive, as well as the possibility of autonomous use, are also among the important criteria that determine the scope of use of the device. For example, when choosing a wrench for tire, preference should be given to pneumatic models, for household needs - electric wrenches.

In addition to pistol grip wrenches, devices with a straight body are also produced, which make it possible to tighten and loosen fasteners with less effort, but it is also tiresome to work with such a tool for a long time.

For professional use, it is better to purchase wrenches, the body of which is made of metal, and plastic products are also suitable for domestic use.

Proper attention should be paid to the assembly of the wrench with nozzles of the necessary shapes and sizes - they should ensure the possibility of performing all the work required during the production cycle.

The cost of the tool is a factor that largely depends on its other characteristics and functionality, so the price of the tool should be considered in the last instance, giving priority to the criteria described above.

Electric and battery wrenches

If, in any workshop, the question of which wrench is better, electric or pneumatic, will be treated at least condescendingly, which is explained by the obligatory presence of compressor equipment in such workshops, then for domestic use the optimal choice will also be obvious and just the opposite. We have already got used to the fact that most of the tools in the home workshop have an electric drive, but if you perform a certain range of tasks it may turn out that the power grid will be inaccessible. In such situations, a cordless wrench can be an alternative to a network tool. Possessing high autonomy, it has more weight due to the battery, usually located in the lower half of the handle. If the work done autonomously with fasteners can be long, you should think about purchasing models equipped with two batteries, although in most cases a spare battery can be purchased separately if an urgent need arises.

One of the best wrenches

A great advantage when choosing a battery wrench will be the presence of LED backlighting, since such works are often performed in conditions of insufficient illumination. A tool with a grip should be selected in cases where access to the threaded connections with a wrench with a pistol grip is difficult.

Modern lithium-ion batteries (like lithium-polymer counterparts) are characterized by a sufficiently large capacity, which allows you to continuously work for a long time without the need to recharge the device. The degree of discharge of the battery is usually indicated by a special indicator located on the body of an autonomous wrench.

Among the drawbacks of electric wrenches, one should note the danger of using such a tool in rooms with high humidity.

Here is a small rating of the best battery wrenches:

- by price availability - Enkor AKM1811;

- torque - Bosch GDS 18V-LI HT;

- on a complete set and functionality - Hammer ACD120 PREMIUM.

Hand wrenches

A hand tool is considered the most versatile, since its work does not require the availability of electricity, fuel or compressor installations - enough muscle power working. The hand wrench belongs to such devices, which greatly facilitate the fastening work.

The principle of operation of the hand wrench is based on the transmission of torque through a planetary gearbox. To attach the head to the spindle, you can use both the cartridge itself and the head extension. Manual rotation of the input shaft is facilitated many times by the gearbox, so when unscrewing the nut, it is enough to apply a little effort, as well as for the reverse operation.

Hand-held wrenches are an indispensable tool for truckers and make it easy to dismantle the wheel in case of emergency situations far from populated areas. Drivers call this tool grinders because of external similarity and the same principle of actuation.

The disadvantage of such a tool can be called the lack of impact, which can complicate unscrewing stuck threaded connections.

Hand Wrenches Rating:

- reliability - BelAvtoKomplekt;

- по функциональности - AvtoDelo 260VE;

- for ease of use - Garwin GRLS-4800.

Pneumatic wrenches

If we compare the ratings of pneumatic and electric wrenches, then it turns out that the pneumatic tool, despite the possibility of functioning with a source of compressed air supply, is ahead of electrical devices in absolute sales figures. The reason for this phenomenon is simple - the absolute majority of service stations of the most diverse levels cannot do without the use of compressor units; therefore, it is more expedient for them to use an impact pneumatic wrench.

A similar situation began to take shape in the construction sector, where the pneumatic tool gradually replaces the traditional electric one.

Compared to electrical and battery-like counterparts, they are less bulky (both in weight and in size) and are safer (they can be used in rooms with high humidity and dust generation, with the presence of flammable / explosive substances).

The principle of operation of a pneumatic wrench is similar to a classic power tool, with the exception of the drive, since it uses compressed air energy. Structurally, such devices are much simpler, since they do not have an electric motor, because the source of energy is external.

When choosing a pneumatic pliers should pay attention to the performance of the tool: in some cases, the pistol shape is impractical. In particular, with the conveyor organization of the technological process, a tool with a straight handle will be more convenient. But the “gun” is more convenient to work “on weight”, for such wrenches there is a huge number of nozzles and accessories.

One of the conditions for durable operation of pneumatic devices is the requirements for the supplied air: it must be dry, contain a minimum of dust and other contaminants, it is recommended to enrich the air with special oil.

As a rule, the service life of pneumogrunners is higher than that of electrical analogues, and their cost is lower at the same power and torque.

Their main disadvantages are the need for compressor equipment, which is far from being everywhere, and the lack of the ability of most models to adjust the spindle speed.

When choosing a wrench, pay attention to its power

When choosing a pneumatic wrench, the power / productivity of the compressor should be taken into account: it must match the capabilities of the tool, otherwise it will not be possible to develop the maximum force specified in the device passport.

The list of recommended models depending on various criteria:

- in terms of price availability, the best pneumatic impact wrench - AIW-01 from the Kraton company;

- on the degree of reliability - Scorpio YU1200-P;

- largest torque - Fubag 100194.

Hydraulic wrenches

Wrenches of this type are relatively rare, since their operation requires the presence of a pumping station or high pressure hydraulic pipeline.

When choosing a hydro-nut wrench, it is necessary to take into account that, unlike pneumocand wrenches and electric wrenches, they are able to create a much greater force, which is inaccessible to other varieties of this tool. As a rule, such devices are used in the chemical industry, in industries where heat-exchange equipment is actively used, that is, where fastener flanges are under great pressure.

There are cassette and cap hydraulic nuts. The first ones are used for work in hard-to-reach places due to the small diameter of the spindle and the flat shape of the tool itself. However, when using special nozzles, such a possibility is also present with devices of a cap-type, which differ from cassette ones by the large force applied to the bolt connection.

Due to the increased power, the body of the hydro-wrenches is made of high-strength steel grades with pronounced anti-corrosion characteristics. The hydraulic cylinder, which is subjected to the greatest loads, is made from aviation alloys, light and strong.

To connect the hydraulic tools to the liquid high-pressure line, coupling halves of various shapes, sizes and configurations are used, oriented to most of the standards used in this field.

The main disadvantages of such equipment are limited scope of use, as well as the need to use a hydro-nut wrench by qualified personnel.

Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru Gaskets from Bosch

adom.ru Gaskets from Bosch

A small list of recommended models:

- Hydrogaykovert GG6000 from the company Enerpred differs the highest created effort;

- The most comfortable to use is the Enerpred GKG500 cassette model;

- By price, the best choice is Bosch GDR 10.8Li.

Cargo wrenches

Repair of heavy equipment in most cases is associated with the need to work with fasteners of large sizes, requiring the application of considerable effort. And if the nuts and bolts are stuck, which happens all the time, one cannot do without a specialized tool. Such devices are cargo wrenches. There are many varieties: pneumatic, mechanical, electrically operated, manual, and the latter are usually used to carry out repair work in the field, and all the rest, as a rule, work in stationary conditions.

A common feature of all cargo wrenches is the ability to develop considerable force, usually with the use of a pulse-impact effect, as well as large head sizes and nozzles. In this case, a high spindle rotation speed is usually not required of this tool.

Since the cargo wrench belongs to highly specialized devices, its cost is quite high, that is, the appropriateness of the acquisition depends on the scale of use.

Wrench for trucks

The list of the best cargo wrenches, depending on commonly used criteria:

- POLARUS-12, a freight electric wrench;

- reliability is no match for the Nordberg IT4250;

- Dino Paoli 256BG has the best features.

Mechanical Wrenches

The basis of the design of a mechanical tool to facilitate the implementation of mounting operations based on the use of a multiplier. His task is to convert muscular effort into rotational movement of the spindle with multiple amplification of torque. Thanks to this, even without having outstanding physical parameters, you can easily unscrew the most outdated and boiling bolted connections.

The multiplier is a planetary gearbox equipped with gears made of high-strength steel grades. As a rule, mechanical wrenches have a cylindrical body with an emphasis that facilitates work in difficult conditions and reduces the size of the tool.

A feature of such devices is the possibility of a smooth build-up of efforts to break loose joints, which significantly reduces the risk of thread damage.

Like cargo types, mechanical nut drivers, despite the relative simplicity of the design, are quite expensive, especially if they are equipped with quality bearings.

The most obvious area of use of such devices is associated with the possibility of self-boring wheels of heavy trucks in the field, while the risk of damage to the studs is minimal.

Mechanical Wrench from Stankoimport

Recommended Mechanical Wrenches:

- for torque, the KA-1315 model can be distinguished from the domestic company Stankoimport;

- reliability - WiederKraft WDK 87921;

- for ease of operation - WP 56M from ROSSVIK.

Gear Wrenches

Many of us, when carrying out repairs, have repeatedly encountered situations where ordinary keys turned out to be powerless in front of stuck bolted joints, covered with a thick layer of rust. In such cases, it is justified to use gear wrenches - tools that provide a significant amount of output when applying relatively small.

This is achieved by using a single-stage planetary gearing in the construction of the tool, which is repeatedly amplified by the employee's muscular effort. In some models there is a switch that provides different spindle speeds. As a rule, gear wrenches are offered with a set of various heads that provide work with the most running fastener sizes.

A feature of this type of device is the need to engage both hands, while due to the large gear ratio, it is often difficult to catch the moment of force needed to reliably tighten the bolt connection.

Gear Wrench

Rating the best gear models:

- largest torque - ATF-4011A;

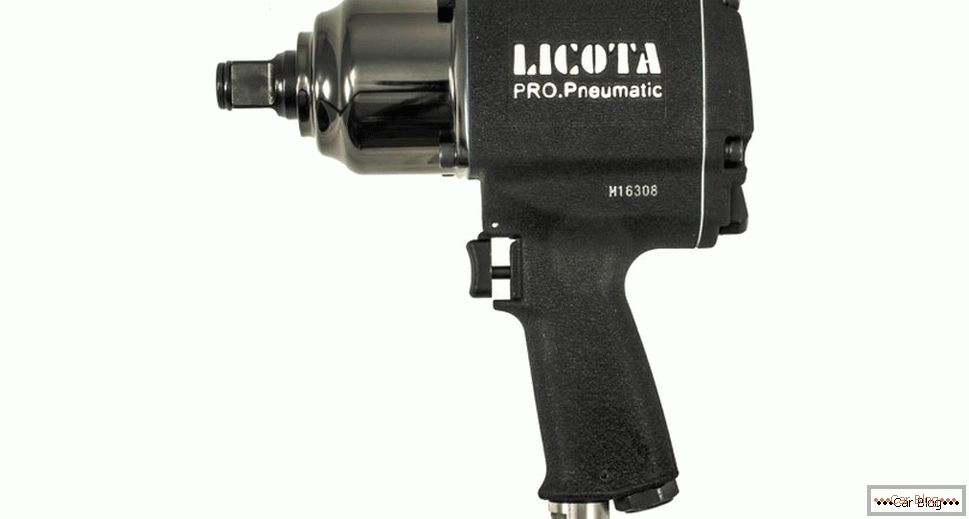

- по функциональности - wrench from LICOTA;

- by equipment - GARWIN GRLS-4800L.

Adjustable torque tools

Many high-tech operations involve tightening threaded connections with a strictly specified torque. For these purposes, torque wrenches are used, however, for large volumes of work, their use becomes irrational. Mechanization of these operations allows nutrunners with adjustable electronics torque. A good network wrench is supplied with sensors, a microprocessor chip that processes the incoming information from the sensor, and a display that visualizes it. In this case, the necessary torque can be programmed, and then everything will be performed in automatic mode. It is possible to control the torque and manually, focusing on the readings of the display.

Adjustable torque wrenches are usually manufactured in a waterproof and dustproof design, and an electronic control unit protects the device from overloads, which affects the increase in durability of the electric drive.

The best models allow you to tighten connections with an accuracy of about 1%, so this tool is often used on conveyor lines, where it is important to ensure high repeatability of operations. Among the disadvantages of such an instrument are relatively high noise levels (from 80 dB and higher) and high cost.

One of the recommended wrench models is MAKITA 6905B

List of recommended models:

- on power - Zubr ZGUE350;

- for ease of use - MAKITA 6905B;

- on accuracy of the moment of an inhaling - 4power 4PE-62S.