>

Often, if you need to carry out car body repair, you have to use a putty. This is a special automotive putty, which are used to work on metal or plastic, as the basic materials of manufacture of the machine itself.

Car body puttying

Рассмотрим вопросы о том, какие бывают шпаклёвки для автомобиля и как выбрать подходящий вариант состава.Читать далее о рейтинге шпаклевок для кузовного ремонта авто-->

Kinds

All automotive putty on the market is divided into:

- fiberglass;

- rough;

- finish;

- liquid;

- universal.

Choosing putty based on the planned work and the nature of the damage to the car body. Only with the help of a good and well-chosen mixture can you achieve the desired result.

Auto-putty is a finishing material, presented in the form of powder or ready-made paste. The powder is diluted in the required proportions, while the paste is completely ready for use. Putty mixture is required for finishing the damaged surface of the car with the subsequent application of a paint and varnish layer.

In simpler terms, it is necessary to putty the car in case of damage, chips and scratches that disturb the attractive appearance of the car and potentially threaten the gradual spread of corrosion.

Putty used in the repair of both metal and plastic parts. But not every putty is suitable for certain tasks. It is important to understand which mixture to choose, what are its features and advantages over competitors.

We choose correctly, taking into account key factors and with an emphasis on achieving the optimal quality of body repair. To pick up the composition, you need to examine each type of putty.

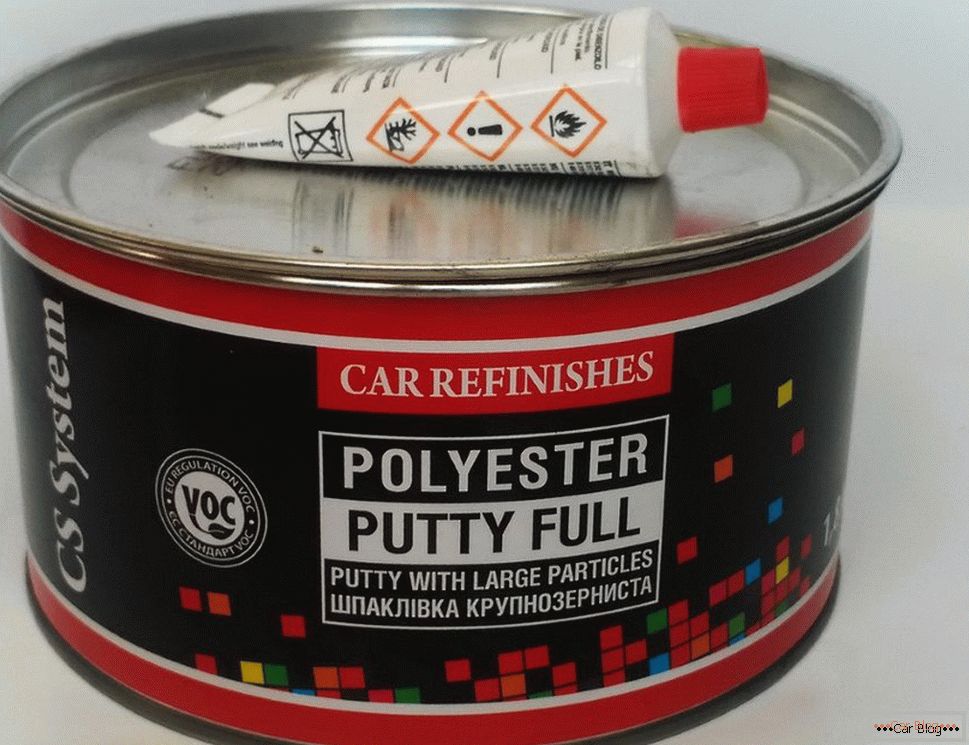

Rough

Rough шпаклевка используется при больших повреждениях кузова

Rough шпаклевка используется при больших повреждениях кузоваОна же крупнозернистая. Подходит для сложных работ, когда речь идёт о серьёзных кузовных повреждениях и дефектах:

- dents;

- holes;

- deformations, etc.

Differs in the entry into the composition of a special filler of metal shavings. This ensures a better connection and increase the strength of the treated area.

The most popular coarse putties are mixtures based on aluminum filler. They are heat-resistant, plastic, elastic and easy to grind after drying.

Due to its features, coarse car putty ensures leveling even major damage. If we talk about manufacturers, then Solid and Mixon are among the leaders.

Never cook too large portions of coarse putty because it hardens quickly. Approximately 4 - 7 minutes after mixing the components, the composition will no longer be applied to the body. Therefore, prepare the mixture based on how much you really have time to use putty.

The rough type of composition interacts with almost all other types of car putters. The coarse-grained appearance is used for rough work, and then thinner putty mixtures are applied.

Fiberglass

Widely used in body repair fiberglass putties

The key advantages of fiberglass car putty are high strength and long service life. The main role in this is played by fiberglass itself, which is part.

After treatment of the body, the mixture acquires solid fractional properties. In fact, when applied and dried, you get a layer of fiberglass.

An important aspect in favor of fiberglass is its ease of processing and grinding. You will be able to give the surface the desired shape and a high degree of smoothness.

Fiberglass has become widespread in body repair, where it is necessary to seal through holes, holes and other similar effects from the effects of corrosion.

After drying, the composition crystallizes, due to which the processing process is somewhat more complicated. It will take a lot of time to work, but the result will be fully justified.

Fiber and Novol are among the leaders in the production of fiberglass fillers.

They have several features in terms of application:

- Fiberglass formulations are easily applied to the treated, clean metal and even to the old paint layer.

- The main condition for obtaining a high-quality result of processing is the preliminary degreasing of the surface. Not with gasoline, but with a good special solvent.

- Fiberglass putties consist of the main component and hardener. Before use, the main part is thoroughly mixed, since precipitation from solid fractions may appear during storage. The light fractions go up at the same time.

- Ensure that the mixture has a uniform color and consistency before use. In the open air you can store no more than 10 minutes. Therefore try to keep it with the lid closed. Otherwise, the mixture will harden and will be unsuitable for further body repair.

- The most important in the proper preparation of fiberglass putty is respect for proportions. The main mass accounts for 3% of hardener. That is, for 1 kg of base, 30 g of hardener is required.

- When the proportions are selected, the components should be thoroughly mixed until smooth and applied to the prepared surface. The drying rate is affected by the characteristics of the mixture itself, as well as the air temperature.

Finishing

Finishing putties are used for minor damage.

This putty is used mainly in cases where you need to correct minor damage and irregularities. Often works together with a coarse mixture and is applied after a rough repair.

Finishing compositions based on fine-grained components. It can be used independently when processing of scratches or chips arising on the metal surfaces of the car is required  Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru .

adom.ru .

Most often, the finishing compositions are relevant for the final processing. Mixtures are divided into two categories:

- Fine;

- Nitro.

They are equally effective in repairing minor damage. They are easy to process and grind. The main task of the finishing putty is to prepare the repaired surface for painting.

The advantages include excellent adhesion, filling capacity, elasticity and resistance to temperature changes.

It is important to knead this putty properly to fully reveal the positive qualities of the composition. Apply the mixture with a layer of up to 3 millimeters on the previously treated and prepared surface.

There are 2 - 3 parts of hardener per 100 parts of base. That is, here we are talking about 3% of the total mass. Calculations are easy to make when choosing proportions.

It is important to quickly and thoroughly mix the components until a homogeneous mass. Finishing putties quickly harden, because to prepare large portions at once is not worth it.

Drying speed depends on the characteristics of the mixture and environmental conditions, but usually takes no more than 30 minutes. After drying, the treatment is fine-grained sandpaper, which allows you to fully prepare the body for painting.

Liquid

Liquid putty features high processing speed

This is a new name in the world of automotive putty. They differ in light fraction and are applied using a special pistol.

Features of the composition can handle not only minor damage, but also large areas of the car body. The advantages include high processing speed. But the rate of hardening is lower when compared with similar compositions. Drying takes 2 hours and more.

If you decide to choose a liquid type of putty for cars, do not forget about the need to purchase a special tool. Special skills for the treatment of the body is not required. The mixture is filled into the tank of the pistol and applied to the surface by spraying.

When the filler hardens, it needs to be sanded and proceed to further paint and varnish activities.

Universal

Universal putty is used for fast body repair

From the title it is obvious that the key advantage is universality. Such mixtures combine the properties and advantages of fine-grained and coarse-grained compositions.

Mostly they are used for fast body repair, when the car owner has no time for thorough processing. The compositions are durable, quite elastic and provide a smooth treated surface.

It is applied putty by analogy with other types of structures for body repair. Proportions are respected according to the manufacturer's instructions.

Useful recommendations

As you can see, it is better to focus on the nature of the damage when choosing a car putty. This will decide which mixture is best suited in a given situation.

At the same time, there are general rules for all that need to be followed when carrying out body work and using putty for car compositions.

- Degreasing. This is one of the key rules, ignoring which usually leads to a low quality result of the work done. For degreasing, some use regular gasoline. But this is not the optimal solution, which is not suitable for some types of fillers. Therefore it is better to use special solvents. When repairing the bumper of the car, make sure that the applied solvent does not damage the paint layer. It is better to glue the whole sections of the tape.

- Necessary types of putty. Depending on the nature and complexity of the damage, you may need one or more types of mixture. Decide on this in advance so that you do not have to interrupt work and run for a new putty.

Only cleaned and degreased surface will work well with putty.

- Stripping. Any treated surface is pre-cleaned. The most relevant tool for these works is sandpaper grit from P60 to P180. Only the cleaned, degreased and dried surface will optimally interact with the filler.

- The speed of work. Auto-putty do not tolerate delays. Features of their properties that they quickly harden and become unsuitable for work. Follow the manufacturer's instructions for storage, and dry the mixture in small portions to make a paste.

- All proportions are selected strictly in accordance with the recommendations of the manufacturer. Because before work, read the instructions.

- Spatulas. Since the mixture is applied with a spatula, one universal tool will not help to thoroughly process the surface. Prepare several types of spatulas in advance.

Based on these rules and instructions from the manufacturers of car putty, you will easily carry out all the necessary repairs yourself.

It is impossible to say unequivocally which of the presented mixtures is better or worse. It all depends on the nature of the damage. Not the last role played by the manufacturer. Choose putty leading brands, the quality and characteristics of which you will be sure.

Subscribe, leave comments and ask your questions! We will try to answer them! Tell your friends about us and wait for new interesting materials!