Clutch drive is a very important part of the car. Even the slightest fault in the drive can lead to the complete absence of the possibility of further operation of the car.

Transmission - the main node of the car, for the stability of which the clutch must function properly.

Purpose of the clutch drive

If there are problems with the clutch, first of all we pay attention to the installed drive. Clutch actuator - a system designed to enable or disable clutch by pressing the diaphragm spring. To date, there are the following types:

- Mechanical - the most common in passenger cars. The main advantages are the prostate structure, reliability of work and interchangeability of system elements, as well as the low cost of repairs.

- Гидравлический clutch drive – работает по принципу тормозной системы в автомобиле, то есть имеются нагнетательные цилиндры и рабочая жидкость в системе трубопроводов.

- Electro-hydraulic type of motion transmission to the shift fork is installed in cars to control the operation of the clutch with a robotic gearbox.

Из чего состоит clutch drive

Due to the completely different principles of operation of the mechanical and hydraulic drive, they consist of various elements.

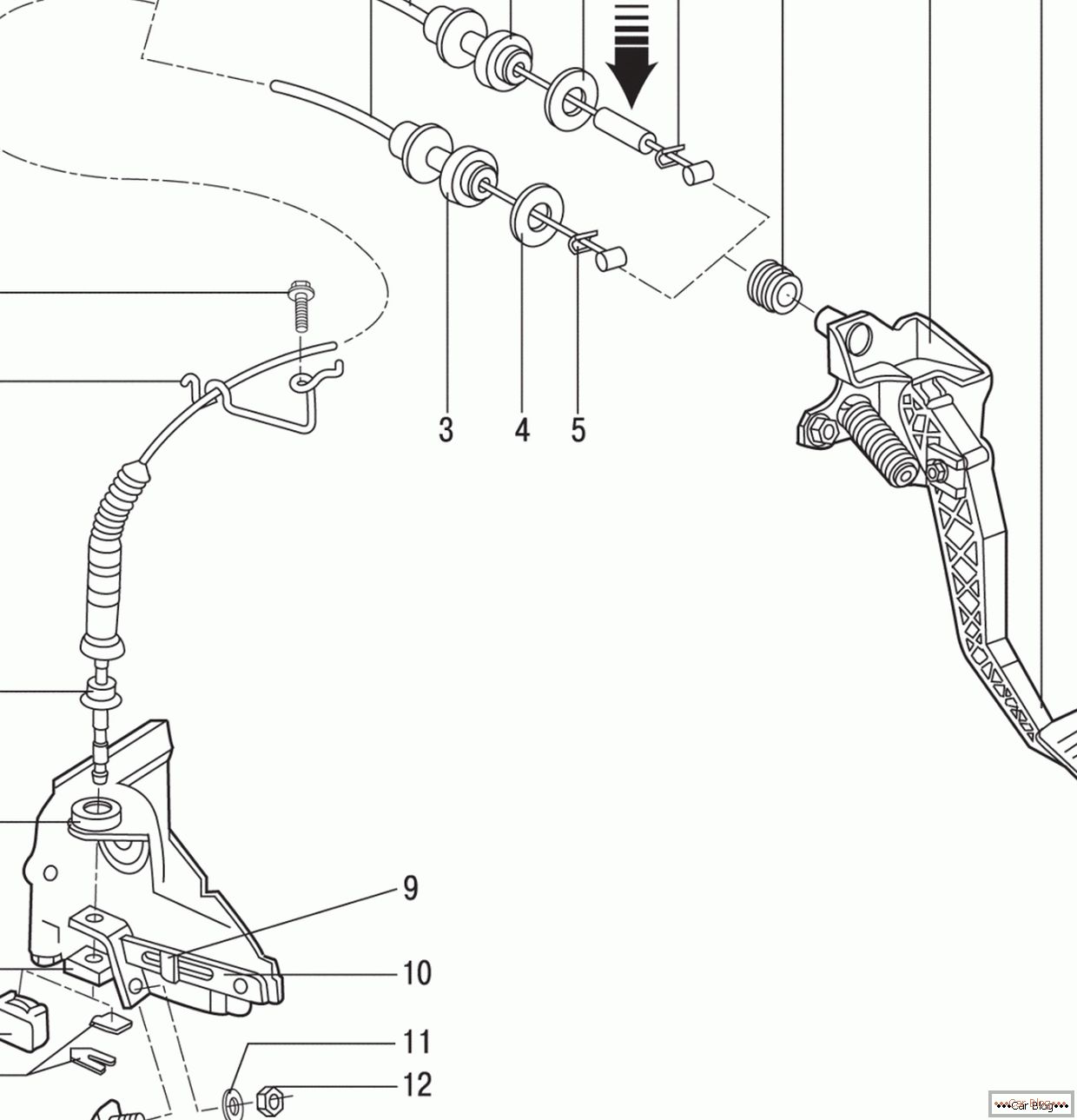

The mechanical drive consists of the following parts:

- The clutch pedal, which is installed in the cab of the car.

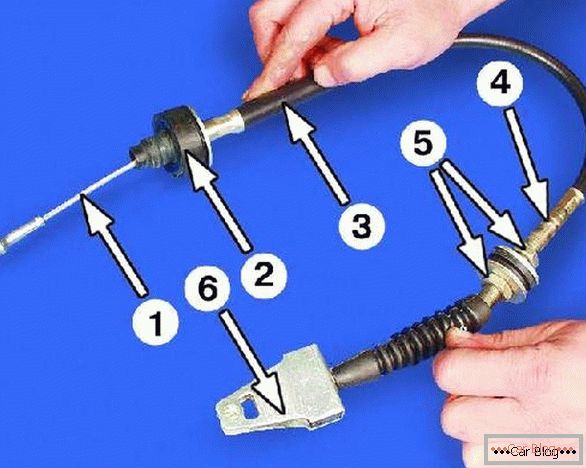

- Drive cable. It is thanks to this link that the movement is transmitted from the pedal to the clutch engagement mechanism, namely to the shift fork.

- Clutch pedal control mechanism.

- Lever gear.

The clutch actuator is adjusted using a special mechanism that limits the pedal travel. The adjustment takes into account the wear of the clutch discs during operation of the vehicle.

The clutch actuator is adjusted using a special mechanism that limits the pedal travel. The adjustment takes into account the wear of the clutch discs during operation of the vehicle.

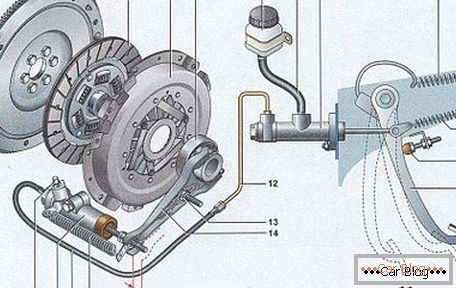

Hydraulic drive type consists of the following elements:

- Clutch pedal

- The main executive cylinder.

- Capacity for storing the working fluid.

- Working cylinder

- Piping system

The hydraulic clutch actuator is based on the use of a working fluid and two cylinders. When the pedal is pressed, the main executive cylinder, consisting of a housing, a rod and a piston, pushes the fluid through the tubes to the working cylinder, where the piston with the rod moves under pressure and, in turn, rotates the clutch shift fork.

The electro-hydraulic system is very similar to a conventional hydraulic drive. The only exception is that the cylinder is actuated by issuing a command from the car’s computer and operating a special compressing mechanism.

Main malfunctions

The main malfunction of the clutch actuator is the failure of one of the elements of the system due to wear.

In the mechanical drive of the clutch, the cable that connects the clutch pedal and the shift fork often fails. Due to wear, the cable may tear, twist or stretch, resulting in a deterioration of the clutch.

The main causes of problems with the operation of the hydraulic clutch actuator may be the following:

- Not tightness of piping systems.

- The absence or small amount of working fluid in the system.

- Failure of one of the cylinders due to wear of the cuffs, stem misalignment or damage to the outer casing

In the case of an electro-hydraulic system, problems with the electrician, the mechanism that drives the cylinders, and the drive control system can be added to the above-mentioned faults in the hydraulic system.

In the case of an electro-hydraulic system, problems with the electrician, the mechanism that drives the cylinders, and the drive control system can be added to the above-mentioned faults in the hydraulic system.

The clutch drive must always be in good condition, therefore it is necessary to timely contact specialized service centers, where experienced craftsmen will be able to carry out high-quality diagnostics and repair of individual drive elements.