Before carrying out soundproofing measures, the driver must clearly define their main goal. As a result of such works, you can improve the sound of music in the cabin, get rid of creaking noises, improve comfort. On the basis of this, consumables are selected, which will be used during the vehicle arrangement.

If the insulation is done with your own hands, it is not necessary to engage in refitting the entire cabin. Such work can be done in stages, and at the same time improve skills. You can start with less significant parts, gradually moving to those whose effect on noise protection is more significant. Normally, sound insulation works are required for the trunk, floor, doors, etc.

The tool you need for noise insulation measures:

- hair dryer;

- roller for stitching;

- metal cutting device.

Materials widely used for sound insulation

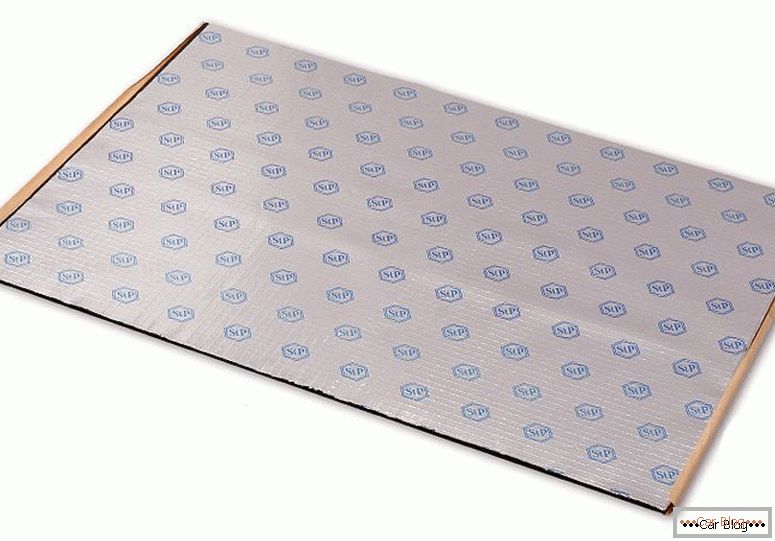

Vibroplast Silver

The most commonly used material. It is flexible and elastic. It is produced in the form of a self-adhesive film composition of noise-insulating materials on aluminum foil. The tape 2 mm thick has a square marking that facilitates cutting on details of various configurations and the sizes. The material does not interact with water or moisture, does not self-destruct, does not rust, and has the qualities of a sealant. It is easy to mount on the surface with complex shapes. Places of application: roof, doors, floor, bonnet and luggage covers, part of the cabin on the engine side.

Vibroplast Gold

This material differs from the previous one in that it is 0.3 mm thicker. This provides greater vibration isolation. Material weight - 4 kg per m².

Вибропоглощающий материал Bemast Bomb

The structure of the sheet with a thickness of 4.2 mm consists of a front foil layer applied on a rubber-bitumen base. Material during installation requires heating to 40-50 ° C. It is the best noise absorbing and moisture absorbing material with the most effective efficiency.

It is flawless for creating an audiophon inside the car. Mechanical losses can be up to 0.5%. Specific weight of the sheet is 6 kg per m². Used for drawing on the wall of the body, protecting the cabin from the engine, in the areas above the muffler, the propeller shaft, wheel arches.

Splen 3004

Sound absorber with high thermal insulation properties. Does not interact with destructive substances from the external environment and does not absorb moisture. The thickness of the sheet with an adhesive surface is 4 mm. Designed for mounting on vertical and curved surfaces and can be used at temperatures from -40 to +70 ° C. It has a low specific weight of 0.42 kg per m³. Splenitis 3004 has several varieties - it is splenitis 3008 and splenitis 3002. The thickness of the first is 8, the second is 2 mm.

Recommended article: The instrument panel VAZ 2114 (price) is 15,000 rublesAntiskrip Bitoplast

Five or ten millimeter material performs sealing and noise absorbing functions inside the car. It is made on the basis of the adhesive layer of polyurethane foam with anti-adhesive specially impregnated gasket. Bitoplast-5 is not a source of odor distribution, it is not destroyed by the adverse effects of the external environment, it shows its functional properties at low temperatures perfectly. Weight - 0.4 kg per m².

Acoustic Accent 10

Ten-millimeter material for sound insulation of the car consists of several layers, based on elastic polyurethane foam and adhesive mounting layer. On the other hand, the sheet is glued over with metallized film. The product has high heat-shielding capabilities. Noise absorption is up to 90%. Sheet weight - 0.4 kg per m². Temperature conditions at which the material does not collapse, from -40 to + 100 ° C. It is used to handle hoods, trunk covers, engine compartments.

Madeline

Материал выполняет уплотняющие и декоративные функции. Изготавливается на черной тканевой основе. Толщина составляет 1-1,5 мм со слоем клея. Ткань защищена водонепроницаемой прокладкой. Madeline используется для декоративного закрытия зазоров в салонах, панелях приборов, а также для уплотнения воздуховодов.

This is not a complete list of tools and materials used for soundproofing a car. All other products are identical in terms of technical characteristics and properties and differ little from those already mentioned.

Noise protection hood cover

The use of noise-absorbing materials for processing the engine compartment cannot guarantee the removal of motor noise. But such events can significantly reduce the noise load on users and the environment, and at the same time provide thermal insulation of the vehicle in the winter season. For the treatment of the hood and its cover is suitable insulation material Accent 10 and vibroplast Silver.

Soundproof hood, you should consider the weight of materials. If it is redundant, over time this will affect the state of the shock absorbers, they will have to be changed ahead of time. Thermal insulation material Accent of any thickness is convenient in that it retains heat in the winter, is resistant to high temperatures and does not ignite even from the heat that may occur during engine operation. The material is not heavy, so the thickness of the finish does not damage the insulation prevention.

Recommended article: Diesel BMW X3 with manual transmission - an excellent crossover for RussiaAttention! Factory hood upholstery must remain intact. It can not be removed. Noise protection is an additional way to isolate and insulate the hood, and not an alternative. Choosing the thickness of the accent, you should consider the gap between the “native” upholstery layer and the free space for the noise insulation film. It is possible that some car models do not have factory insulation. In such cases, you can use insulating materials of maximum thickness. Usually it is 15 mm. In conjunction with vibration isolators, they will create the most effective result.

Anti-noise car door treatment

Noise-proof door measures improve the protection of the vehicle interior against external sounds, temperatures, and optimize the internal acoustics. To ensure noise protection in the minimum volume, vibration isolators of the Silver or Gold brands will be required. They are attached to the back of the speakers. The more coverage you can cover, the better for acoustics.

If the metal is thin, it is recommended to use a shimo insulator with maximum thickness. It is not desirable to weight the structure, since this will affect the functionality of the doors and hinges. It is best to apply an integrated approach with the use of thin different types of noise absorbers.

Vibroplast Gold or Silver are used as the first layer. It is specifically opposite the speaker is recommended to put Bimast bombs. The second layer is formed with a 4 - 8 mm layer of vibration-proof splenitis. The inside door space in which the loudspeaker is located must be airtight. This action will give the door extra strength.

The next stage is sound insulation of door cards. They should not make squeaks or other sounds. To do this, use antiskrip Bitoplast. The more you use this substance, the better. С помощью вещества Madeline обрабатываются внутридверные «сверчки», тяги и ручки. There is no difference between the technique of pasting the front and rear doors. In the case when the speaker is not arranged in the door, vibration-proof materials are used in smaller quantities, and their range can be narrowed down to the most elementary ones.

Soundproofing ceiling space

Such events allow you to protect the vehicle interior from the penetration of noise coming from outside. When it rains, unpleasant noise, comparable to the roar, will be reduced to a comfortable minimum. For finishing the ceiling used vibroplasts brand Gold or Silver. The ceiling should not be heavy, because the weight of the machine should be as low as possible. As a sound absorber is applied four or eight millimeter splenitis. It is allowed to overlay the material in several layers. The main thing is not to forget that the noise insulator does not interfere with the correct tensioning of the ceiling covering.

Recommended article: Chinese Great Wall Hover in the secondary marketNoise floor protection in the car

The installation of noise insulation is caused by the need to protect the interior of the car from noise caused by wheel friction on the road surface, hitting stones, etc. High-quality heavy materials such as bimast bombs are used for this. Top additionally applied 4 or 8 mm splenitis. It may not be convenient to lay a thick coating immediately, so you can make several thin layers.

During internal noise insulation, it is important that in places where wheel arches are located, to make reinforced multilayer noise insulation with the same Bimast bombs. If this is not possible, you can use the vibroplast brand Gold in several balls.

Materials for sound insulation of trunk, wheel arches and niches

Increased attention should be paid to the spare wheel niche. It is recommended to process it several times with a vibration isolator. Plastic plating elements are glued with anti-squeaky Bitoplast. Wheels are the main constant source of lower noise. To improve comfort in the salons of vehicles, the places where the arches and alcoves for the wheels are located are treated with the most thickened film layer.

Such activities are performed in the following sequence: Lockers are removed, the surface of the body is cleaned. Vibroplast and anti-gravel are applied to the inside of the arch. The latter gives not only noise protection, but also protects against corrosion. Plastic wheel arches are also used. If necessary, they are additionally treated with a sticky substance. If everything is done correctly, the driver and his passengers will feel in the greatest possible silence that can be achieved while the vehicle is moving.

Noise isolation provides unlimited opportunities to improve the conditions of use of vehicles. Despite the fact that the car manufacturer initially takes care of this, the use of anti-noise materials allows you to create additional barriers to the penetration of extraneous tiring sounds. In some cases, anti-noise treatment is also anti-corrosion. This makes it possible to more effectively take care of the condition of the car and extend its life without costly repairs.

And then a video about car noise isolation: