Rear caliper guides are necessary to perform certain tasks such as monitoring the quality of the brake system and proper braking. But nothing is everlasting, and this part has the ability to quickly wear out, although this is influenced by the model and make of the car. Due to stress on the braking system, the temperature of the rims and caliper can reach up to 500 ° C.

Temperature deformation may occur due to a sharp temperature drop. They lead to low performance of the braking system due to the weak fit of the clutches to the working surface of the disks. Also, wear is affected by the external environment: water, dirt, sand, and more. A good effect has a lubricant for guide calipers.

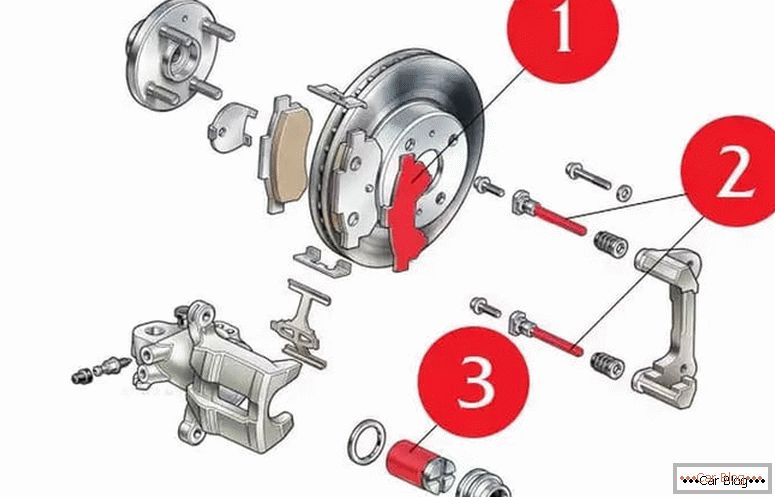

If with each careful inspection of the brake caliper, or when it is fully replaced, it is necessary to lubricate all its parts:

- guide fingers;

- brake cylinder;

- fixing parts.

If you ignore or treat with unsuitable lubricants, you can bring the components of the caliper to a non-working state.

Content

- 1 How to lubricate the guides of the brake caliper

- 2 What is better lubricant for guide calipers

- 2.1 Mineral or synthetic pastes with metal impurities

- 2.2 Lubricant, based on mineral oils

- 2.3 Lubricant based on synthetic oils

- 2.4 High-temperature materials

- 3 Lubrication technique

- 4 Analysis of the most popular lubricants

- 4.1 Molykote Cu-7439 Plus

- 4.2 MS-1600

- 4.3 SUBJECT VeryLube

- 4.4 SLIPKOTE 220-R

- 5 How not to buy a fake

Чем смазать направляющие тормозного суппорта

To make the right choice of lubricant for the guide pins, the piston of the working cylinder and the retaining clips, you must know the basic requirements when choosing lubricants:

- the material used should not change the surface of the product, that is, the lubricant should be sparing to the parts of rubber, all types of plastic and metal, which are components of the braking system;

- it should not lose its purpose when interacting with brake fluid, water and other aggressive elements that may affect its action;

- grease for brake calipers should retain the ability to withstand high temperatures to the maximum set by the manufacturer limits, because at elevated temperatures, it can lose the necessary viscosity parameters and just drain from the place of processing;

- It is important to maintain quality at lower temperatures, such as -35 ° C, since this threshold can be achieved in domestic climatic conditions in many regions;

- for extreme conditions requires the use of specialized more expensive formulations, the parameters of which are specified in the instructions for use.

The use of other lubricants may damage the brake caliper and cause a traffic accident.

What is better lubricant for guide calipers

According to its characteristic features used by motorists lubricant guide brake caliper, is divided into four categories. For each composition uses unique chemical components.

Mineral or synthetic pastes with metal impurities

This is a high-temperature silicone grease, the meaning is in maintaining its abilities up to 200 ° C (each lubricant is valid when there are different temperature indications). The substance contains synthetic or mineral oil, with the addition of a thickener mixed with metal compounds such as copper or molybdenum. They can be divided into the following types of pastes:

- complex lubricants, with the addition of copper, aluminum and graphite compounds;

- copper, their composition is copper metal powder and graphite powder;

- pastes, which include ceramics and MgCiO3;

- disulfide molybdenum grease.

This category includes such greases from world-famous brands that are often found on the shelves: LIQUI MOLY, Wurth, Huskey, Loctite.

See also: Why is the ABS sensor litMineral oil based lubricant

They are prepared with the addition of natural clay material, which in the composition is used as a thickener. It is added in the form of a powdered metal or fatty acids. The positive point in this case is that the substance has the ability to operate the composition in different temperature ranges starting from minimum values of -45 ° C and ending with a critical degree of + 180 ° C. This suggests that the lubricant does not spill and retains its characteristic qualities.

When used in a lightweight environment - this is the best option for lubricating guide calipers. Substance is resistant for different aggressive environments:

- brake fluid;

- plain water;

- alkaline solutions;

- acid environments.

Also, the tool has a good lubricating ability. Pastes have a poor ability to evaporate, as well as they have a low dielectric constant. As an example, we can offer the following brands:

- Teroson VR500;

- ATE Plastilube;

- Loctite Plastilube.

Synthetic oil based lubricant

The composition is unified, and has wider application than previous substances. Its operation has an extended nature and is aimed not only at lubricating the caliper, but also for processing other parts in the car. Lubricating pastes are developed from synthetic oil that has been refined and have many advantages:

- have a positive effect on blocking foci of corrosion;

- have an antioxidant effect;

- reduce the degree of wear of parts.

In the composition there is a thickener. Lubricants from this category have excellent physico-chemical characteristics:

- do not dissolve in water;

- do not interact with brake fluid;

- almost neutral to acid and alkali;

- they do not evaporate when the temperature rises during operation;

- characterized by low electrical conductivity.

The approximate operating temperature range of the majority of brands on the market falls within the range from -40 ° to + 500 ° С.

High temperature materials

Because of its ability to withstand high temperature ranges, when the braking system is operating, copper caliper grease is a high-temperature grease. The main composition of copper lubricants includes three main components:

- crushed fine copper;

- synthetic mineral oil;

- other types of substances that prevent foci of corrosion.

The release of lubricants is carried out in different form factors:

- in paste form;

- in a vision spray;

- as sprayers.

In most cases, the material has a viscous feature. Due to such properties, it is able to penetrate deep into the figured cavities without pouring back.

If you choose to use copper grease, for this you need to thoroughly clean the surface of the entire part. Drawing is carried out very carefully, it is necessary to control that particles of garbage on working material did not get. Excess grease no need to clean.

Copper grease should not be used if the transport support is made of aluminum, because aluminum corrosion will occur. Copper and aluminum have galvanic incompatibility that is used in other situations.

Lubrication technique

Some drivers, due to inexperience, do not know how to carry out the lubrication procedure on their own, because they have never used similar formulations. When repairing or replacing the braking system, you must perform a certain series of actions:

- If you hear creaking when braking, you must lubricate the metal (not friction!) Lining in the brake pads. It is necessary to lubricate very carefully, on both sides so that the lubricant paste does not leak onto the piston of the working cylinder. Lubricate carefully the surface so that the lubricant does not flow out of the anther.

- Also, brake pads and pressure springs are to be processed for smoother movement. All is applied neatly, avoiding the processing of the friction work surface.

- The constant use of such lubricants and timely monitoring will undoubtedly prolong the life of the brake calipers and adjacent components that make up the braking system.

Analysis of the most popular lubricants

There are many different lubricants on the market. We need to determine among the huge selection of assortment what the best lubricant for calipers would be better. Consider some of the highest quality, according to drivers, lubricants from different manufacturers in demand.

Molykote Cu-7439 Plus

The basis of this lubricant took semi-synthetics and copper particles. Manufactured in the United States of America. Designed to handle brake calipers, and therefore has certain requirements in the appointment:

- possibility of use at temperature scales from -30 ° С to 500 ° С;

- evaporates badly;

- resistant to flushing;

- complete lack of water solubility;

- the best degree of protection from corrosion and scale formation.

According to drivers, this is one of the high-quality lubricants having protective functions.

MS-1600

Lubricant Russian production. It is created taking into account operational domestic conditions. Also in demand by drivers because of the ability to withstand various temperature fluctuations. This lubricant has been tested in the harshest working conditions. MS-1600 has a protective ability against the effects of alkali, acid and water.

Apply grease in the processing of front and non-work pads. Also does not react with brake fluid. Available in a package of five grams, which is enough to handle a complete set of brake pads.

XADO VeryLube

One of the lubricants with a reasonable low price. Quite qualitatively fulfills its purpose at different temperature scales ranging from -35 ° C to +400 ° C, and also has a neutral attitude to rubber parts.

Note the need to apply more than one layer of this lubricant, which will ensure the protection of parts to the maximum level. A minor drawback to which you can not pay attention, is that the composition is a very thick mixture.

SLIPKOTE 220-R

A very benign product that can be used on a temperature scale from 45 ° C to + 350 ° C. It has high-quality protection against corrosion deposits and overheating. The composition of the lubricant included a lot of impurities.

The negative characteristic is the high cost of this material and inaccessibility, it is not so easy to buy it. The best solution is to order from abroad, through the websites of foreign retailers or car companies. Lubricant can be purchased from these brands:

- Permatex;

- TRW Autospecialty;

- Pennzoil;

- Loctite;

- Toyota.

How not to buy a fake

Before you click on the "basket" button on the Internet, inspect first the packaging of the lubricant being purchased. As a rule, fakes are made in a tube of low quality, on which not all information is printed or there are no signs bearing distinctive character.

To save someone, you can order counterfeit products, which will help you in saving your money, but there will be no guarantee of quality work in such a situation, and as a result, everything can lead to a failure of brake calipers, discs and guides. And as a result, such savings will result in additional costs for car repairs.

Important! Before applying the lubricant paste, carry out high-quality cleaning from dust and dirt of all parts.