Domestic cars can be repaired independently in any convenient garage. Their design provides the maximum level of maintainability of all units and mechanisms. In this case, the head of the block will not be an exception; one of the operations of this process is the replacement of valve guides.

WITHодержание

- 1 Mechanism design

- 2 Need to replace the sleeves

- 3 Vypressovka of plugs

- 4 Запрессовка ремонтного комплекта

Mechanism design

During the operation of the valve mechanism, the movement of the valves occurs in a confined space. The direction to move is determined by the alignment of the hole in which the axis of the rod and the inlet / outlet “moves”. Material for the rod selected the most wear-resistant.

WITHталь легирована большим количеством хрома и никеля. Направляющие втулки клапанов, сопрягающиеся со штоком, выполнены из менее прочного материала, чаще из медесодержащих сплавов. Это связано с тем, что ремонтный комплект таких втулок будет стоить дешевле at обслуживании, чем полная замена клапанов с износившимся штоком. Также пара сталь-латунь гораздо лучше работает at фрикционном сопряжении.

Replacement sleeves

There is practically no gap between the hole and the valve. This and the presence of seals on the rod helps to prevent the ingress of oil into the combustion chamber. But due to the fact that the operation of the valves takes place in aggressive conditions and with intensive movement, wear on the sleeves appears, they have to be periodically changed. If they did not stand in the design, then I had to change the entire head of the blocks after working in the holes through which the rod goes.

Need to replace the sleeves

Износ можно определить по нескольким косвенным atзнакам, также есть случаи, когда требуется менять втулки в обязательном порядке:

- into the combustion chamber motor oil penetratesDue to this, its consumption increases and grayish smoke is formed from the exhaust pipe;

- audible characteristic tapping from the head of the block;

- at complete replacement kit valves;

- overhaul head block.

Tool for pressing out

Vypressovka of plugs

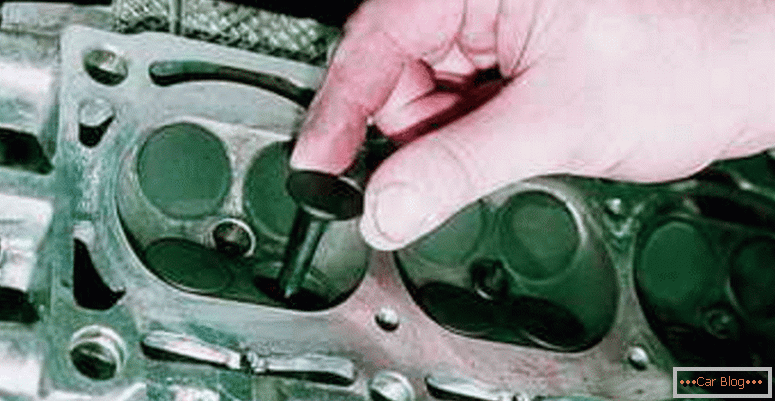

The most popular method of extrusion is shock. We remove the dirt from the previously removed block head. Then we fix it on the workbench. For the operation, you need a special puller, brass or bronze cylindrical mandrel with a length of 80-100 mm. WITH одного конца на ней должна быть проточка на длину 30-40 мм диаметром на 1-2 мм меньше, чем диаметр внутреннего отверстия втулки. The mandrel should have a maximum diameter, not larger than the outer size of the sleeve.

-

- Step 1. Heat the head of the block

-

- Step 2. Press the bushings out.

-

- Step 3. To make a comparative measurement of the rods and holes

-

- Step 4. Scan holes

Before knocking out sleeves, необходимо нагреть головку atмерно до 100-120WITH. This is done to reduce the tension between the sleeves and the housing. In the garage, suitable electric stove. In no case should you use a burner for this operation in order not to overheat the metal and not to spoil the “geometry” of the surface of the body part. Need to beat out from the side of the combustion chamber.

After releasing the bore, it is necessary to measure its diameter. This is necessary in order to properly choose the fit, the difference between the size of the new sleeve and the bore diameter. The repair sleeve must be 0.03-0.05 mm larger. This will ensure a tight fit. Measurements should be carried out on the cooled head.

Запрессовка ремонтного комплекта

In order not to damage the surface of the holes and not to create a teaser, before replacing the valve guides, it is necessary to reheat the head of the block a little again. Repair kit for a better fit to cool. For this suitable household freezer. Without such manipulations, high-quality pressing can not be obtained, and then all of them quickly "loose their arms" in their places. And it will be necessary to disassemble the node again.

WITHборка механизма

When everything is in place and the head of the unit is cooled to ambient temperature, it will be necessary to process the holes with a scan. Such a calibration will bring the diameter to the desired size over the entire length. It is desirable to use a customizable tool, since wear and tear occurs on the uncontrollable, and after a large number of treatments, the size of the hole will be slightly smaller than the required one. Due to this, the valves will pass with pressure, overcoming friction, or they can simply stick.

Normal is the gap between the valve stem and the hole 0.03-0.04 mm.

After pressing the sleeves, it is possible to adjust the valve seats. For this operation are used cones or countersinks.