Hydrocompensator - performs the role of preventing the appearance of gaps between the camshaft and valves, i.e. they compensate for valve clearance.

Principle of operation of the hydraulic compensator

When the engine is running, it doesn’t fill the inner part of the hydraulic compensator, after which due to a constant change in pressure, the plunger cyclically moves, thus preventing the formation of gaps in the valve drive, thereby keeping the camshaft cam and rocker contact.

Such behavior, hydrojackers much easier to repair and maintenance of internal combustion engines, precise adjustment of valves during the repair loses its need. It must be said that the hydraulic compensator is very sensitive to the quality of the oil.

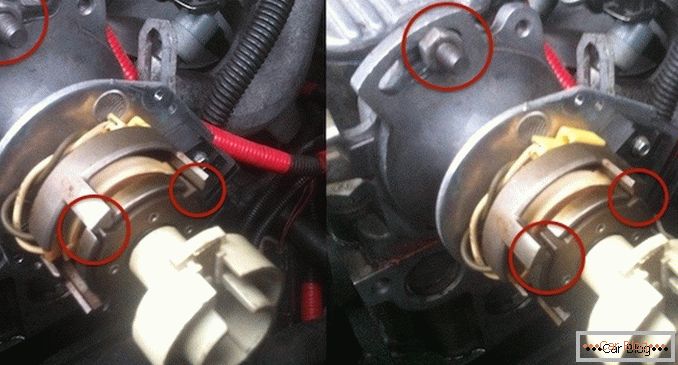

Locations and types of hydraulic compensators

Hydraulic compensators are divided into two types, namely for motors such as DOHC and SOHC. In their structure, they are not too distinguishable among themselves. The hydraulic compensator is a rather “thin” system, placed in a sealed capsule. In engines like DOHC it is installed in the sockets, which are located in the cylinder block. Well, motors like SOHC hydraulic lifters in the jacks of the rocker arms.

Device of hydraulic compensators

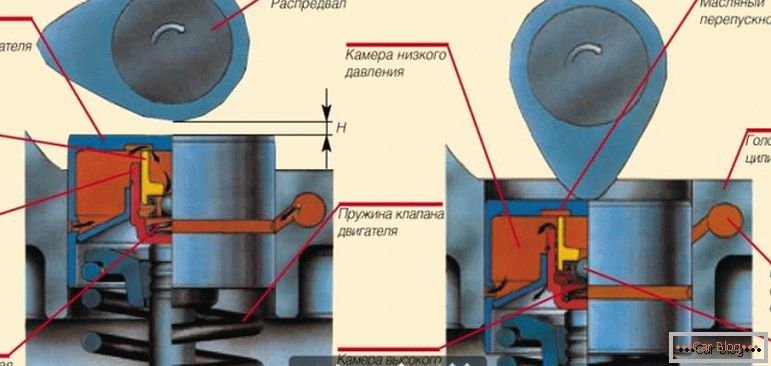

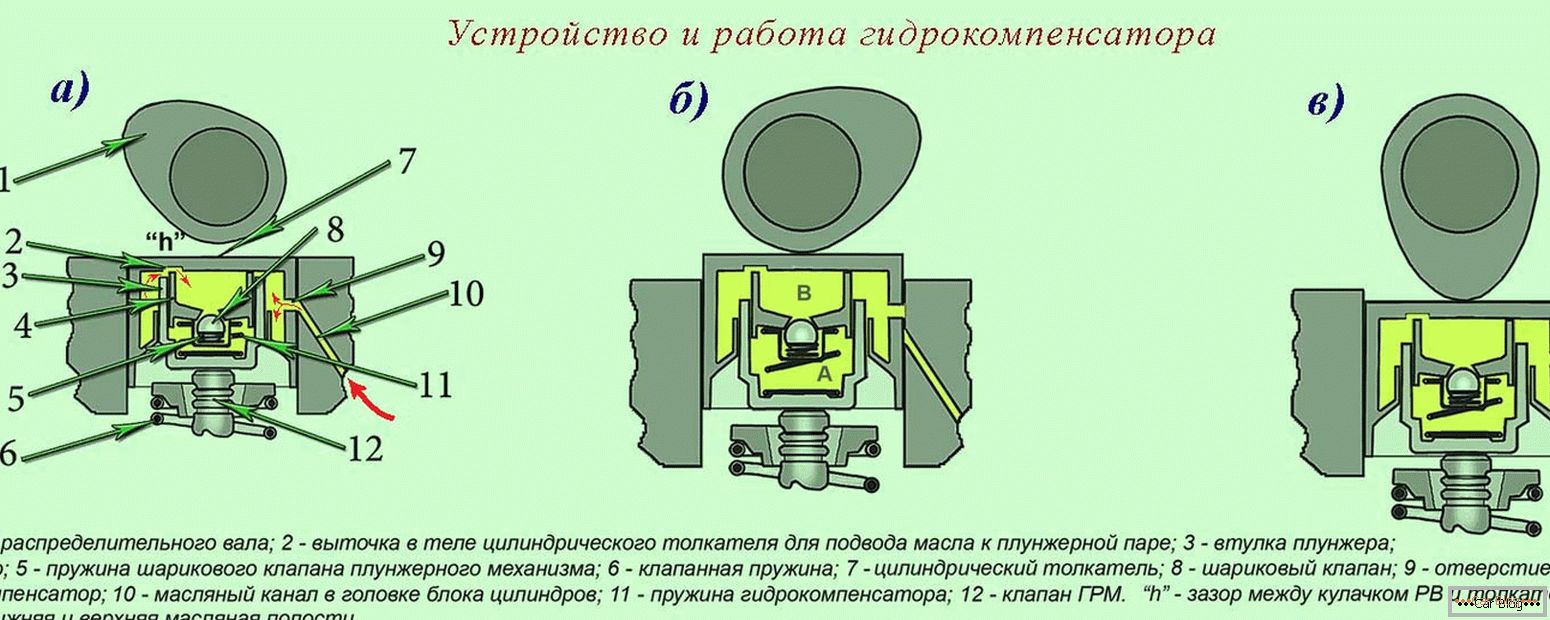

The system of the device of the hydrocompensator, though “a thin thing”, is not at all complicated. The hydraulic compensator consists of a valve, a plunger, a piston, a housing, and a retaining ring. When the engines are running, the camshaft cam is at the top of the movement, with the rear side relative to the compensator.

As a result, the lifter does not take any effort, which allows the inner spring to squeeze the plunger, thanks to this the gap disappears. Oil enters the space that appeared under the plug through the valve. After full filling of the hydraulic compensator with engine oil, the pressure inside the engine and the pressure of the hydraulic compensator is compared and the valve closes.

See also: Removing and cleaning the throttle: causes of pollutionWhen the cam of the camshaft turns to the hydraulic compensator with a convex side, it begins to push it down under the force. The compensator filled with engine oil has a sufficient rigidity in order to transfer lossless effort to the moving camshaft, and they, in turn, to the timing belt. In this process, a small part of the oil comes out of the hydraulic compensator, resulting in a small gap, which was at the beginning of the whole cycle.

The principle of operation of the hydrocompensator allows you to prevent working gaps of the internal combustion engine, and also does not allow gaps even when the engine is hot, and gaps associated with wear of the timing.

Signs and causes of breakers

The first reasons for the failure of the hydraulic compensators, is poor-quality oil, which in turn clogs the oil channels and high wear of the working surfaces of the check valve and plunger.

The first symptom of a malfunctioning hydrojammer is the characteristic sound of the engine, both at revolutions and at idle. Such a problem can be caused by the presence of air in the cavity of the hydraulic compensator (usually with an insufficient level of oil in the engine or in rare cases with a long-term idle time of the car with a large slope). Engine oil that is not replaced in time also affects the performance of the hydraulic compensators. And of course the hydraulic lifters themselves are not eternal. They can fail due to their fairly long service life.

The reason for knocking the hydrocompensator on a warm engine:

- Incorrect operation of the oil filter;

- Motor oil of poor quality;

- Oil pump defective;

- The oil level is minimal or the oil is above normal;

- The landing site of the hydraulic compensator is “broken”;

- Самоизнос гидрокомпенсаторов;

- Hydraulic compensators do not get the engine oil at the right pressure;

- Oil channels clogged.

Trouble-shooting

Sometimes it is possible to eliminate such a malfunction with your own hands in the garage. You can try to wash the hydraulic lifters and be sure to clean the oil channels. But first, just check the engine oil level, if necessary, bring it to the proper level. To get rid of the air in the hydraulic compensator, start the engine and at least ten times slowly accelerate it.

If the knock is still present, check the condition of the compensators. You may find the following damage:

- Corrosion on the plunger surface;

- Wear body hull;

- Hard pusher stroke.

Of course, it is better to do such work at the workshop, there can be a lot of reasons for this, and unfortunately one cannot do without special tools and skills.