The presence of an injector in modern cars implies a fuel injection system through nozzles. Unlike the carburetor, nozzles have a simpler design, but they are quite demanding on the quality of the fuel. But I must say that everything is not so simple. Sophisticated electronics, which regulate the amount of injection and are undoubtedly responsible for the quality of the combustible mixture, may malfunction or fail altogether. Thus, problems with injectors can be much more than with a banal carburetor. If you know for sure that the injectors in your car are clogged up, you probably shouldn’t panic and hurry to drive the car back to the garage.

Should I contact the service?

Repair nozzles on socialized service stations, the task is quite expensive. Do not rush to give your car masters, try to determine the need and washing nozzles, and fix this problem in your garage. If for example a breakdown happened in a Nissan car, then perhaps solving the problem would not be a difficult task. Since these cars are notable for their unpretentiousness (the exception is the models of new generations) and the possibility of self-repair even in the most difficult situations in your opinion.

The first signs of malfunction injectors

Your car can work with increased fuel consumption, while its power will be much lower. The motor starts to work unstably (troit) and even stall. Thick exhaust fumes are possible from the exhaust pipe. The simplest version of the malfunction can be a banal decrease in the dynamics of the car. When overtaking or fast acceleration from a place, you will certainly feel that the former power of your car has disappeared.

See also: Removal of catalysts

Injector Prevention

Do not forget that the diagnosis of the injector (if you are not sure about the quality of gasoline in your region) is carried out every 5 thousand km., Or every 10 thousand km. with complete cleaning of the injector. Try not to stint on the diagnosis in these terms, because it will give you the opportunity to be confident in the health of your car.

Flush injector

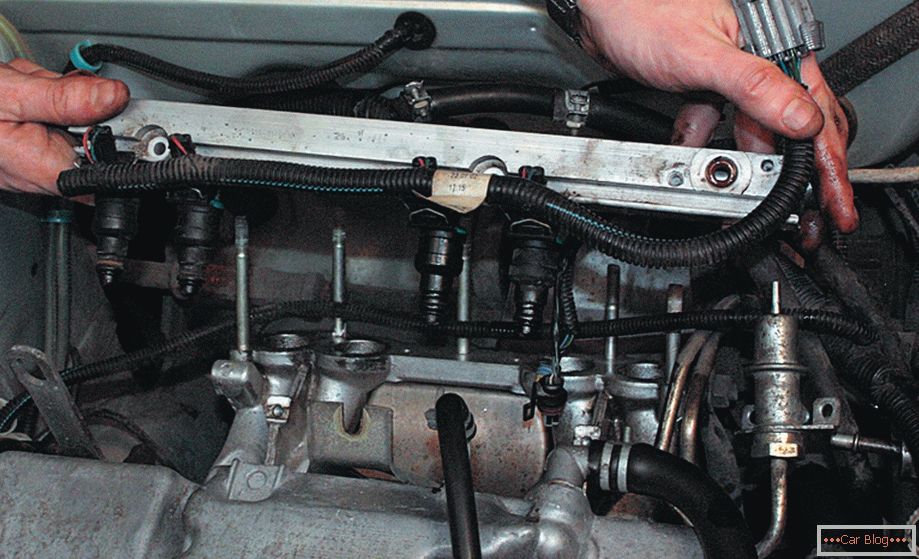

When flushing the injectors, you will need a tool to flush the injectors. The chemical composition of this tool will remove third-party elements from the fuel flow channels. It will be enough just to drive out the fluid under the available pressure in all spray channels of the nozzle. You will need to remove the rail with nozzles, while disconnecting the power supply to the nozzles and remove the fuel supply hoses. After that, remove the nozzle rings. If the rings have become quite stiff, then they should be replaced.

Each of the nozzles is flushed separately, you will need wires with terminals to connect to a power source that will produce from 9 volts to 12. Do not forget, you need to clean the nozzle channel under high pressure. To do this, you can take an ordinary medical syringe, take the washing liquid into it and, with a strong pressure on the syringe, drive all the “chemistry” through the nozzle. After pre-flushing with a syringe, connect our terminals to the power supply. So we simulate the operation of the valve, by turning on and off the switch. It is necessary to pass the flushing fluid at the maximum possible pressure, so that we can clean the channel seats and fuel channels. After several such procedures, the nozzle should be put aside, thereby giving it time for the oxidation process. After a five-minute oxidation process, it is necessary to repeat the nozzle washing process several more times. If you did everything right, your nozzles will start working as before.

See also: If diesel fuel is frozen - What to do?

Nozzle installation

Assembling the nozzles and putting them in place occurs in the reverse order. The main factor to be noted is whether a leak occurs at the base of the nozzle. This can be checked by setting pressure on the fuel channels of the injector. For this you can use the fuel pump. To do this, you need to try to start the engine several times without starting it. If there is no leak, start the engine and make sure that it works without interruption. If the work of the motor is correct, then the problem was the “driving” of the injectors. If you are still not satisfied with the work of the engine, then you should first of all clean the injector itself and the throttle valve. You can also check the pressure in the fuel rail, the problem of malfunction in some of its elements, also affects the incorrect operation of the engine.