>

The brake system of the car is designed to slow down or completely stop the vehicle. It includes several components - brake pads, hoses, brake cylinders, vacuum booster, drums or discs. Brake pads - an important component of the brake system of the car, which will ensure the safety of cars on the road. The car is equipped with four pairs of pads - one pair for each wheel.

We will tell you how to make the right choice.

Машины нового образца обустроены дисковыми передними и задними тормозами, если же говорить о классике, то множество автомобилей имеет задние тормозные колодки барабанного типа.Читать далее о выборе задних тормозных колодок-->

Drum or disc brake pads?

Drum-type brakes were previously installed on all cars on all four wheels. At present, this design is outdated, as drum-type pads do not provide the necessary braking at high speeds. Drum brakes often overheat, in contact with moisture cease to work reliably, more difficult to repair. Drum brakes, unlike disc brakes, are less polluted, have a longer service life, and are cheaper to operate.

Used most often in budget cars

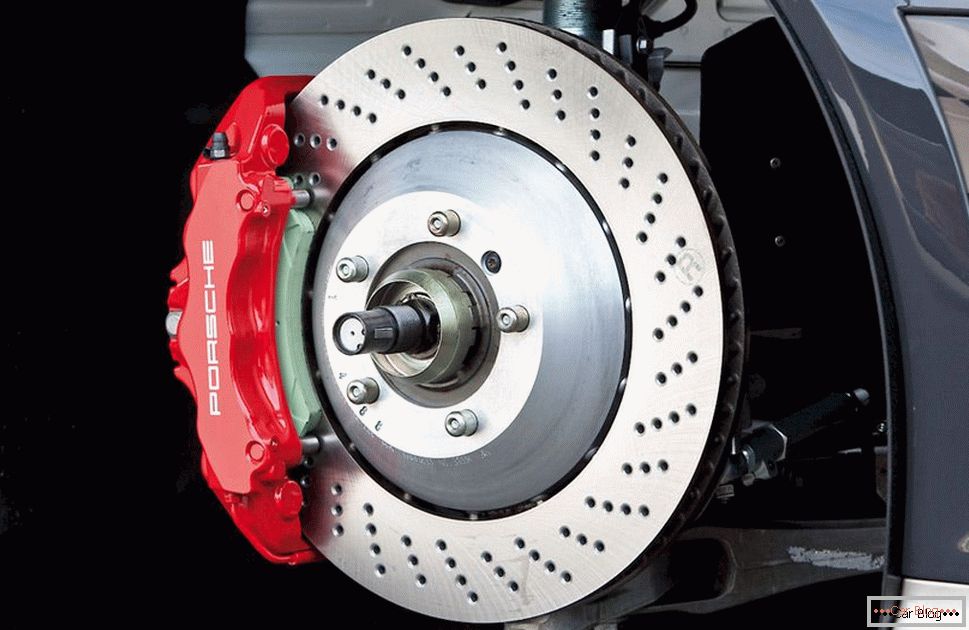

Disc brakes have an open braking system, which contributes to its faster cleaning and cooling. The disadvantage of this system is the rapid production of pads.

More common option at present

If we compare disc and drum braking systems, we can conclude that disc brakes will be more effective when braking. The transition from drum brake pads to disc ones was carried out due to the fact that at high speed drum brakes cannot cope with their tasks. Rear drum brakes can now be found only in budget cars with not very powerful engines, the dynamics of which is small. If we compare the pricing policy, the drum-type brakes are much cheaper to operate. Drum pads require less replacement.

Shoe making material

Pads are plates with a securely fixed friction lining of a certain shape. Its quality is due to the material from which the friction linings are made. The material of the friction lining is different refractory, temperature indicators - the operating temperature of the pads. For standard cars, the temperature threshold is significantly lower than for sports cars and expensive cars. If the pads are not heated to operating temperature, the friction coefficient will decrease, which will lead to their rapid wear.

The service life of brake pads, operating temperature, braking performance and the condition of the brake disc are proportional to the material of which the pad is made.

Types of brake shoes

On sports cars require a more durable design

Semi-Metallic. Their contents include up to sixty five percent of the metal. Pads with such a composition tend to wear quickly, at minimum temperatures they perform their tasks worse, they are noisy when slowed down, although they have a high level of heat transfer.

Organic consists mainly of polymers, such as rubber, carbon, glass, high-temperature resins and filler materials. They are less noisy, but create dust that gets into the ventilated discs, wear out quickly, their braking performance is reduced when in contact with moisture.

Ceramic have a high coefficient of friction and do not destroy the brake disc. Differ in long-term service life. They have a high temperature threshold, because it is a great option for sports cars.  Discounts for new cars! Profitable loan from 9.9% installments 0%

Discounts for new cars! Profitable loan from 9.9% installments 0%  adom.ru. Of the disadvantages - have a long stopping distance.

adom.ru. Of the disadvantages - have a long stopping distance.

Metal-ceramic - are the most modern, are of high strength. They have a stable coefficient of friction, cope with stopping cars in any weather conditions, practically do not heat up and have a low noise level.

Brake pad selection rules

Brake pads have three categories of quality. The first is genuine O.E. series brake pads, which are sold at specialized sales outlets. As such a product, you can be sure that basically such parts are packed in original bags or boxes of the manufacturer’s factory. The manufacturer provides a guarantee for such products and monitors their quality. Their disadvantage is the high price. The product of the second category may have minor deviations from the design documentation, but has certificates of quality and permission to operate. The price of parts is much lower than the goods of the first category. The third category includes products whose quality is significantly lower than that of the manufacturer. A series of products is being exported. The product is made of simpler mixtures, because it has a low service life.

On quality control in the first place original parts

Choosing brake pads for a car is not always easy. There are a few rules to follow when choosing them:

- Packaging. The product must be well sealed and with the sign of ECE R90, which confirms the certification of goods in European countries. Also, manufacturers use an individual code on their product, put special marks on the packaging, provide a passport, quality certificate, warranty card and installation instructions.

- Appearance. Products you are going to purchase should be free of visible scratches and cracks. Inspect the base plate for cracks and deformations. The friction material must be firmly attached to the metal base.

- Design. The brake shoe consists of two elements: the friction material and the base, which is made of metal. The shape of the new and old parts must match the configuration. Pay attention to the thickness of the friction plate. Premium segment manufacturers do not save on materials, respectively, the product will last longer.

- Material. The initial material that is used to manufacture the product should not include asbestos. This material is included only in the goods of a cheap class.

- Options. Carefully study the characteristics of the part - temperature pads and coefficient of friction. The first indicator is viewed from the position for which purpose you have a car. If the machine is used for sports purposes, the temperature should be seven hundred to nine hundred degrees, the optimum temperature for the average driver is three hundred to three hundred and fifty degrees Celsius. The nominal friction coefficient is 0.3–0.5.

Which brake pads are better

The ideal option is to buy the required auto parts from the manufacturer for a specific car model. These parts have a high pricing policy, so we will try to consider equivalent parts that have the tried and tested quality.

An example of installation on a ventilated disk is shown.

Brembo is one of the most famous Italian manufacturers of sports brake pads. Products provide excellent braking and tolerate high temperatures.

ATE is the largest global supplier. Their advantage is the ability to withstand maximum temperatures. This is a premium product that has a high price category.

STS is a domestic manufacturer. This product has a good quality, reasonable price, suitable for driving in urban environments.

NIMBK and LUKAS - high quality products and reasonable price. Of the minuses - hostility to high speeds.

Jurid is an American company that specializes only in brake pads, so its parts are intended for delivery to the assembly plant of automotive plants.

findings

The choice of brake pads is widely represented on the market by many manufacturers who offer different variations of their goods. When choosing brakes you should know that the economical option will provide an opportunity to achieve benefits when buying, but can significantly increase not only the braking distance of the vehicle, but also the cost of maintaining the braking system. Good brake pads - a pledge of fast braking and, possibly, saving lives.