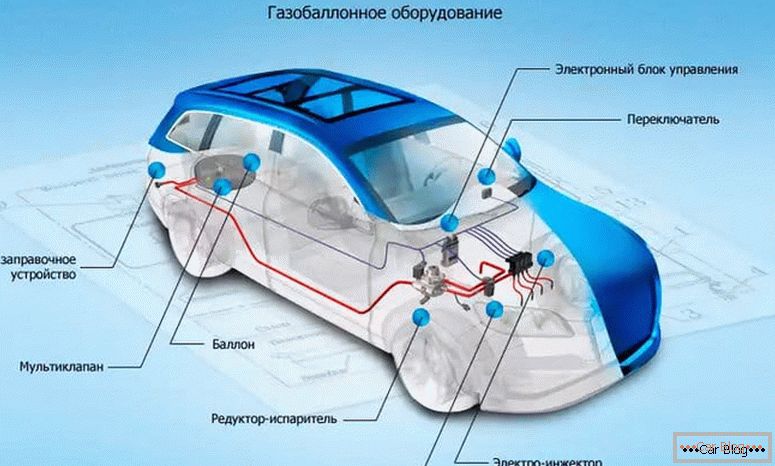

Gas equipment for a car (HBO) is an additional system in a vehicle, which makes it possible to supply the power plant not only with liquid bulk fuel, as the manufacturer envisages, but also to operate at the expense of gas. One of the motivations for installing gas equipment is a positive economic effect. Taking into account the fact that prices for gasoline and diesel fuel are rapidly increasing, drivers often decide to put gas on the car.

By installing HBO on cars, you can reduce fuel consumption by up to 20%, if only quality equipment was selected. In the auto market, we can meet gas equipment of various manufacturers, but the price does not always correspond to the quality of the goods. Various types of liquefied gas such as natural gas (methane) and petroleum (butane-propane mixture) act as gas fuel.

From what type of fuel in the car is used, and what type of engine the car has, cars will be converted to gas-filled vehicles. It is divided into the following groups:

- single-fuel;

- dual-fuel self-feeding of one of the fuel in the machine unit;

- dual-fuel gas diesel engines, i.e., two types of fuel (gas and diesel) are simultaneously injected simultaneously.

Each of these technologies refueling has its own specifics, but it does not exclude common features. Analyzing in stages, the HBO system, emit such factors as "generation". There are five generations of HBO. Gas equipment 4th generation - one of the most economical. It is also distinguished by its easy operation and good compatibility with Russian gas. In the presence of the fourth generation, the fifth for our country does not quite fit in some parameters. The difference is in the injection system: in the Quartet, the gas distributes into separate cylinders, the V generation sends the gas in liquid form directly to the engine of the car.

Content

- 1 I generation gas equipment

- 2 II generation gas equipment

- 3 III generation gas equipment

- 4 IV generation of gas equipment

- 5 V generation of gas equipment

- 6 Is it necessary to put HBO

- 7 How to install gas equipment on the car itself

- 8 Setting the gas installation

- 9 Maintenance of gas equipment for cars

- 10 How often do MOT pass?

I generation gas equipment

All information on this system was set for carburetor and injection cars, with a fuel injection system. The basis of his work lies in the vacuum control of the fuel inlet, mechanical dispenser.

Advantages of the first generation:

- simple structure in the mechanism of the system;

- affordable price;

- the admissibility of use on modes of transport with an injection power unit;

- low fuel price.

The disadvantage of the first generation: in high frost requires the transfer to parallel gasoline fuel.

II generation gas equipment

The principle of operation is based on the operation of an electronic nebulizer that interacts with an oxygen sensor.

Advantages of II generation:

- simple structure in the mechanism of the system;

- less fuel consumption when compared with the first generation;

- low fuel price.

The disadvantages of the II generation:

- increased demand for gas consumption, compared with gasoline;

- during high frost requires conversion to parallel gasoline fuel;

- There is no possibility of mechanical switching between gasoline and gas.

III generation gas equipment

Advantages of the III generation:

- even less fuel is needed when compared with the second generation;

- low fuel cost.

The disadvantages of the third generation:

- quite high cost of equipment;

- during high frost it requires conversion to parallel gasoline fuel;

- there is no possibility of mechanical switching between gasoline and gas;

- increased demand for gas consumption, compared with gasoline.

IV generation gas equipment

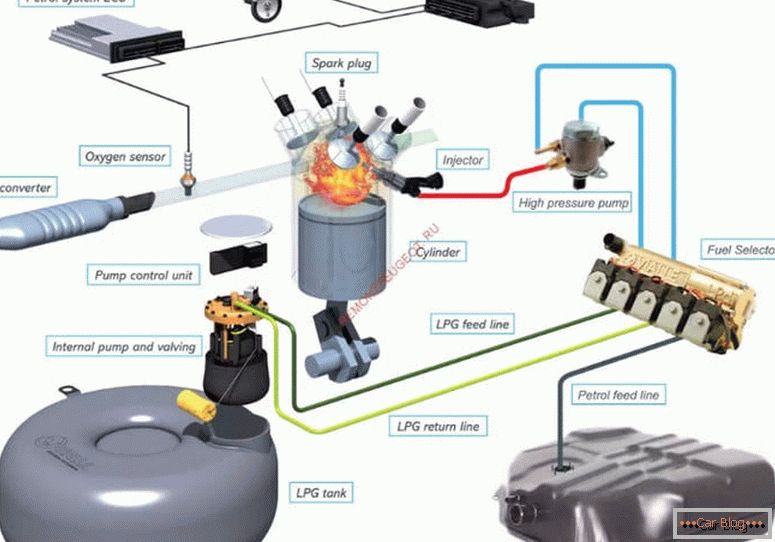

HBO of this generation, carries out its work by methodical fuel injection, due to electric magnetic gas atomizers. Gas diffusers are located on the manifold, near the intake valve, like the third generation.

Advantages of IV generation:

- less fuel consumption, when compared with the third generation;

- существует the ability to automatically switch between gasoline and gas;

- low fuel cost.

Disadvantages of IV generation:

- high cost of the kit;

- in case of significant frosts, a mandatory transition to liquid bulk fuel is required;

- compatibility with engines of machines that use fuel injection directly into the cylinder is excluded;

- overestimated need for gas consumption, compared with gasoline.

Due to electric magnetic gas atomizers, this system provides a parallel and methodical release of gas injection. The operation of gas electromagnetic sprayers is determined using a gas control unit.

V generation gas equipment

In each cylinder of the engine, the gas enters the liquid state, which is the main difference of the fifth generation from the other four varieties. A gas pump is included in the kit for a conventional engine, which in its fuel system distills liquid gas into the gas sprayer ramp, thereby creating the necessary regular pressure in front of the sprayers.

Advantages of the V generation:

- the ability to start the engine on gas fuel at high frosts;

- the ability to automatically switch between gasoline and gas;

- low fuel cost.

Disadvantages V generation:

- high cost of equipment;

- almost impossible to repair;

- high demands on gas quality.

To install the HBO does not need to make any changes to the mechanism of your vehicle. Gas equipment on the car is an additional alternative to fuel, which can always be abandoned and return to the mono-fuel type of motor.

The main change in the design with HBO is an electric magnetic valve, which is built into the fuel line, to be able to turn off the supply of gasoline. Increasing the overall stroke of the car, the valve independently selects the fuel supply to the engine of the car, which is its advantage.

Positive aspects of HBO:

- High profitability.

- Exhaust emissions of pollutants are significantly reduced, because it is environmentally safe.

- Improves engine performance. The engine is quieter and lasts longer.

- Increases the power reserve of the machine. The transfer from one type of fuel to another automatically occurs, thus increasing the distance without refueling.

- The possibility of using gas and gasoline.

- Unpretentious operation.

Negative moments of gas equipment:

- Fuel consumption increases by about 20%, but you need to consider that gasoline is more expensive than gas.

- Not cheap cost of installation work. One-time fee is quite large and it can not be divided into several payments.

- Mandatory conduct regular technical inspection. Such a minus can be considered insignificant, since the driver controls his own car for his own safety.

- The vehicle mass increases.

- The spare wheel has to be carried in the trunk of a car.

Is it necessary to put HBO

The system justifies itself in several cases. For example, if you have frequent trips, the car, which will be in the garage, will not pay off soon. If in the near future you do not expect to purchase a new car, then the system is also needed. If the warranty period of the car has come to an end, the system will be understood. And finally, the system is justified in cases where the engine consumption is about 10 liters of gasoline per 100 kilometers, only after switching to the gas supply system.

How to install gas equipment on the car itself

Installing gas on a car independently requires a certain experience and a stock of knowledge on disassembling and repairing a car. Before installing gas on a car, it is necessary to weigh all the risks and carefully study the process of installing gas equipment.

Consider the main tasks of the procedure and try to identify all the complex issues arising in the process of assembling equipment:

- Select the required installation kit. There are offers from a variety of manufacturers in the sales market, but it is better to pay attention to well-known brands; there are fewer issues with them during installation and subsequent operation.

- Determine the installation location of the pressure transducer (gearbox). If the need arises for mounting pressure transducer holes, they must be machined. It must be fixed in an accessible place, to further facilitate maintenance.

- If electronic equipment is included in the package, it is necessary to determine its installation location In the electronic control unit there are special microcircuits, as well as embedded programs, thanks to which it is possible to adjust the operation of all gas equipment. Any damage to the electronic control unit affects the operation of the electrical power supply, gearbox and exhaust system.

- Correctly fasten gas sprayers (nozzles). Their task is to timely supply the scattered gas to the cylinder block.

- Create holes in the ramp under the sleeve (in vehicles with carburetor engine drilling is carried out in the body of the carburetor). Before drilling the ramp, it is better to remove it, in order to avoid chips inside. Holes should be closer to the fuel nozzles.

- Properly distribute the wires from the electronic control unit to the sensors, gas diffusers and the button in the cabin of the car. Work will be considered quality if the electric wires do not hang down. All trolls need to be connected with brass terminals, and isolate with corrugation. It is important to observe the correct polarity.

- Installation of the cylinder, valves and filling designs. As a rule, they are installed in the place where the spare wheel is located, under the rear seat backrest and under the bottom of the trunk. A place for the fueling unit can be located in the fuel tank flap or in the rear wing of the car. Selection at the request of the car owner.

- Gas pipeline laying. To install gas equipment, both copper and thermoplastic highways are used. The latter are more resistant to corrosion. The gas pipeline is carried out on the bottom, where the pipeline brake and fuel systems.

Gas equipment on the machine at this stage can be considered complete.

Gas installation setup

The first thing to do is to fill the cylinder with gas. Using a soap solution, check all pipe connections for leaks, under pressure.

See also: Anti-skid bracelets on the wheels of a car

Manual adjustment is carried out only in the first generation of HBO. In the presence of an electronic control unit, the regulation of the system is performed using the software stitched to a computer individually.

Maintenance of gas equipment for cars

What is included in the maintenance of gas equipment for cars:

- Diagnosis of the management system of equipment, due to which all its working indices are identified.

- Timely replacement of liquid and vapor phase filters.

- Flushing gas sprayers - if the software detects this need.

- Investigation of the system for tightness.

Do not forget, all received final results on the fact of maintenance, indicate in the service book. This is an exemplary procedure for maintenance for HBO generation IV, for other generations earlier, the process may vary.

How often do MOT pass?

Since the installation of gas equipment, maintenance should be carried out regularly after every 10 thousand kilometers. Once a year, before the arrival of frost, you should inspect the entire gas system. A maintenance book will give you a full list of recommendations.

Certification and inspection of gas cylinders must be held 1 time in 24 months. Those with built-in methane equipment, certification and certification should be carried out - 1 time in 60 months. The check takes place in certain authorized points. Inspection of confirmation is carried out by:

- visual inspection;

- hydraulic test;

- pneumatic test;

- test result.

A cylinder is considered defective if: there are gaps in the places of welded joints, chips on the surface of the gas cylinder. Also the cylinder is unsuitable if the damage sites are clearly identified by physical impact. And, finally, the cylinder is defective, if traces of corrosive damage are revealed, the thickness of which is 10% of the total depth of the cylinder wall.

Increasing the service life allows you to control the consumption of fuel used, as well as to ensure the safety of yourself and your passengers from gas leakage. If a butane-propane mixture is used, it is necessary to use a certain engine oil. Then, you really feel all the positive aspects of using a gas installation.