The clutch mechanism is available in any car, no matter what type of gearbox is installed in it. He is constantly affected by huge loads, the node is constantly experiencing shocks. Of course, the clutch that is installed in a car with manual transmission, rather than with automatic transmission, suffers the most. In order to understand the principle of the clutch, it is necessary to consider its design features. But first things first.

Content

- 1 Key Features

- 2 What you need grip

- 3 Clutch Classification

- 3.1 According to the type of relations of the slave and master parts

- 3.2 According to the principle of education effort

- 3.3 type of drive

- 3.4 By the number of disks

- 4 How does a mechanical clutch drive

- 5 How clutch hydraulic works

- 6 Differences drives

- 7 Instead of conclusion

Main characteristics

The appearance of the clutch mechanism

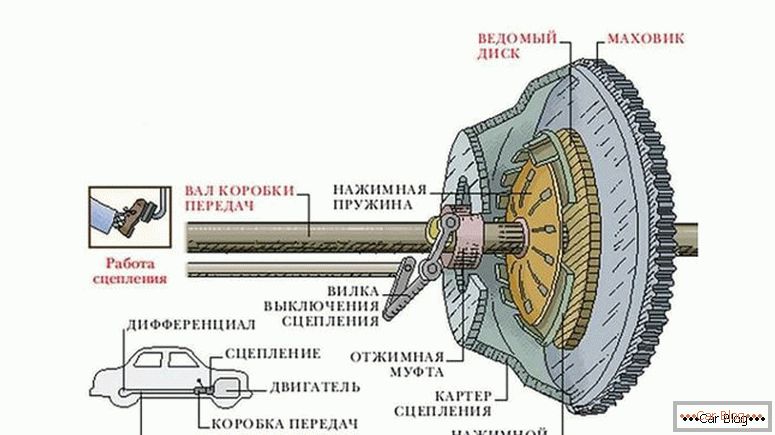

The mechanism is needed to transfer torque from the engine crankshaft to the gearbox. Moreover, the clutch has two states - in one the torque is transmitted, and in the other it is not (when the pedal is pressed in the cabin). In the majority of cars, there is a construction, based on two disks - a master (basket) and a slave. It is also possible to carry out separation according to the type of drive: friction, hydraulic, electromagnetic.

What is clutch for?

At the time of the start of the movement it is necessary to separate the gearbox and engine crankshaft. If you turn on the first speed without this, then the car, if it starts moving, is very sharp. There are also strikes on gears gears. When the clutch is turned off, it is possible to turn on the first speed (for example, in the process of starting off) and, gently releasing the pedal, start moving. Moreover, the torque in the process of releasing the pedal will not be transmitted in full. This allows you to start moving as smoothly as possible.

Turning off the clutch also helps shift gears while driving. Agree, it is quite difficult to turn on the third speed without disconnecting the discs. Of course, this can be done, it’s just worth thinking about what loads the box will experience at the time of gear changes. A load can be significant, especially large occur during engine braking, when the clutch pedal is quickly released, when driving on a rough road, as well as during a decrease in crankshaft speed.

Common clutch device

Clutch Classification

There are several generally accepted classifications of the clutch system:

According to the type of relations of the slave and master parts

Разновидностей сцепления несколько, причем его можно классифицировать по определенным признакам. От этих признаков может зависеть и то, how does car grip work, но, по большому счету, различия имеются небольшие. Как было сказано ранее, можно провести разделение по типу связи элементов:

- Electromagnetic.

- Friction.

- Hydraulic.

According to the principle of education effort

It is possible and for this characteristic to carry out the classification, then we distinguish several types:

- Centrifugal.

- Semi-centrifugal.

- Designs with a spring installed in the center.

- Designs with built-in peripheral springs.

type of drive

Single disc clutch

Here the division is not so rich, there are only two types:

- Hydraulic - with two working cylinders.

- Mechanical - use the cable.

By the number of disks

You can also divide by the number of slaves:

- With one.

- With two.

- Multidisk designs.

All those types that have been discussed above, except for centrifugal, are closed. In other words, the clutch is always on, off when changing speeds Manual transmission, when the car stops.

The designs of friction clutches are very popular today. They are used not only in passenger car systems, but even on trucks, buses of various classes. Coupling with two discs in the passenger cars is almost never used, but it can be found in towing vehicles capable of carrying tens of tons of cargo. Multidisk also applies mainly to heavy vehicles. Therefore, in cars you will hardly find him, but in motorcycles it is used quite often. It should be noted that the electromagnetic type of clutch did not take root due to its complexity and high maintenance cost. Hydraulic automakers also do not like to use. A couple of decades ago, cars with this type of clutch could still be found, but they, as a rule, had a friction element in the design.

Multi-plate clutch

How does a mechanical clutch drive

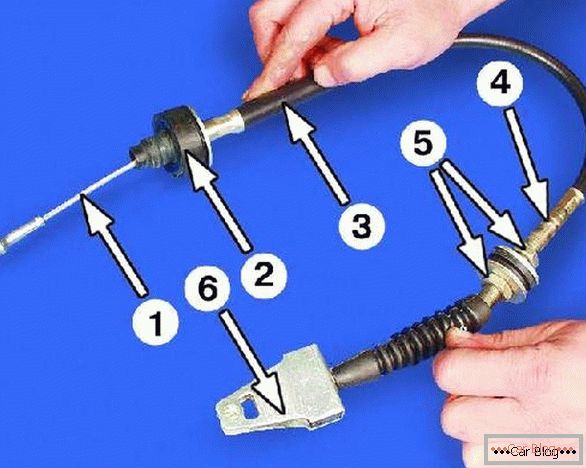

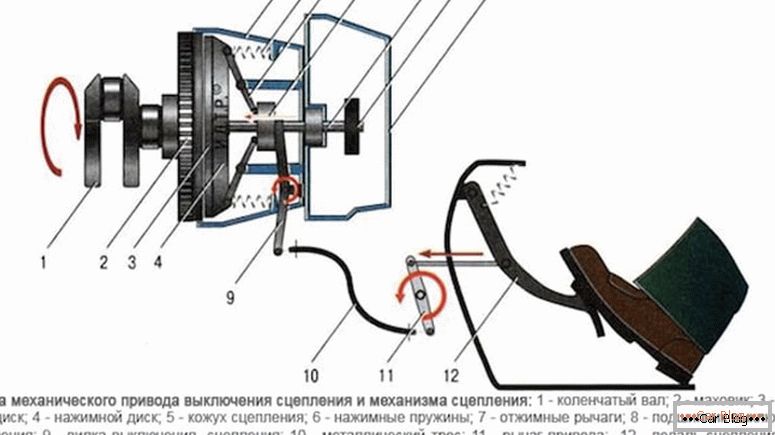

The node works in the same way, regardless of how many disks are installed, how many shafts, and on what principle pressure is generated. But now we will talk about the mechanical drive clutch. We will consider hydraulics a little later and find the advantages, disadvantages and differences. As long as you do not press the pedal, the driven disc will be pressed tightly leading to the flywheel. All torque is transmitted to the input shaft of the box from the crankshaft. When the pedal is pressed, the cable that pulls the fork lever is set in motion. The latter drives the release bearing, which acts on the petals of the basket.

When the bearing is pressed on the petals of the basket, the driven disk is displaced; a gap is formed between it, the flywheel and the driving disk. As a result, the connection between the box and the engine is broken. If you look at the mechanism during operation, you can see that the flywheel with the basket continues to rotate, while the driven disk (located inside the basket) remains stationary. Now you can turn on the first speed and gently release the pedal. Slow pedal release is a smooth build-up of the speed of the input shaft from scratch. When you throw it completely, the number of revolutions of the input shaft of the gearbox will be equal to the number of revolutions of the engine crankshaft. Only in systems with a mechanical drive there is a cable. But its functions can be performed by a liquid

Mechanical clutch

How clutch hydraulic works

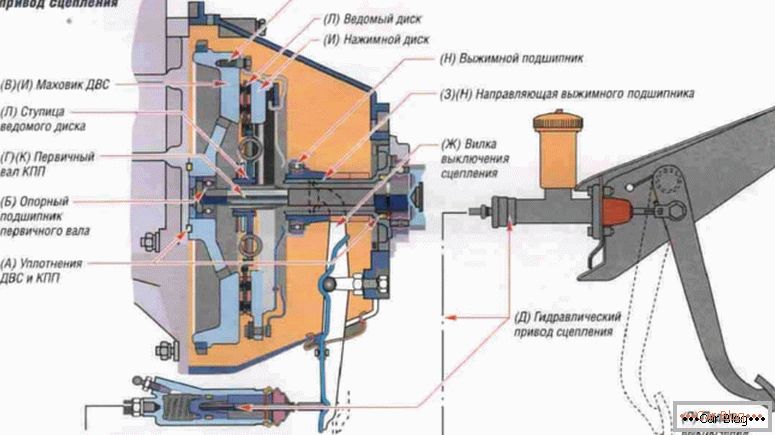

Как было сказано ранее, вместо тросика используется жидкость (например, тормозная). Отличий достаточно много, так как в конструкции вместо одного троса использованы цилиндры и трубопроводы. Давайте рассмотрим особенности и car clutch device с гидроприводом. На первичном валу КПП установлен диск (ведомый). Крепится он при помощи шлицевого соединения. На маховике болтами прикручена корзина, в конструкции которой присутствует радиальный лепесток с пружиной. Педаль в салоне прикреплена к кузову и имеет связь при помощи шарнира с главным цилиндром сцепления. Если быть точнее, то педалью вы приводите в движение поршень в этом цилиндре.

See also: Changing the gearbox oilA similar design mechanism is located in the area of the lever of the fork, only it is called the working cylinder. They are connected by a tube capable of withstanding great pressure. When you need to shift gears, you step on the pedal. The piston in the master cylinder compresses the fluid, creates pressure in the pipeline and pushes the working cylinder piston. The latter drives the clutch fork, which with the help of the release bearing presses against the surface of the basket and disconnects the crankshaft from the input shaft of the gearbox. When you release the pedal, it returns to its initial position under the action of the spring.

The design of the cylinders is very similar. They consist of several parts:

- All-metal case.

- Piston (looks like a thimble).

- The pusher is a solid metal rod.

- Rubber sealing rings.

- Holes for pumping with cone-shaped fittings.

When you press the pedal, the force is transmitted through the plunger to the piston. Due to the fact that the piston is tightly clamped in the cylinder (largely due to the sealing rings), pressure begins to build up in the tube. Further, this fluid begins to act on the piston of the working cylinder. In fact, the same cable, only liquid.

Hydraulic clutch

When the clutch pedal is released, the working cylinder piston returns to its original position under the action of a spring, and all the fluid moves back to the master cylinder. After the pressure decreases, the valve closes. Overpressure begins to form in the hydraulic drive system. As a result, all the gaps that occur in the clutch actuator system are kept at the same level.

Drive Differences

Regarding the mechanical drive, its advantage is that there is no need to maintain it. If defects appear on the cable, they simply change it, since the cost is small. But comfort when driving on the mechanics is worse. Suffering and smooth inclusion. From this side, when viewed, the hydraulics ensures a smooth shutdown of the unit. But the design is complex, you need to ensure that the system always had liquid. And in the case of repair, of course, you will spend a lot more money.

Instead of conclusion

Вот и провели классификацию, рассмотрели the principle of operation of the car's clutch, теперь можно и выдать пару рекомендаций. Надежное сцепление – это залог исправности всего автомобиля. Не бросайте резко педаль, отпускайте ее плавно, это позволит увеличить срок службы всех механизмов. Также не следует долгое время держать педаль в выжатом положении.