An indispensable device for lifting cars is a jack. He put in new cars as a mandatory repair equipment. For passenger cars, a mechanical device is enough, but in order to lift trucks, hydraulics is indispensable. Like any mechanism, a jack can fail, including due to intensive use. For further work with it, it will be necessary to pump the working fluid. How to pump the hydraulic jack, we will tell in our article.

Content

- 1 The reasons for the decline in effective work

- 2 Disassembly and diagnostics

- 3 Oil filling and pumping jack

- 4 Use and storage after repair

The reasons for the decline in effective work

Before proceeding with the repair, it is necessary to diagnose the device. There may be several reasons why the device may not perform its functions. The main ones are:

- airing the working fluid (air bubbles appear in the oil, preventing the transfer of force to the piston);

- corrosion plaque (reduction of passage ducts due to the formation of corrosive formations on the stacks, which reduce the diameter or block the passage for the oil);

- loads that deform the working rod (the bent rod passes tightly in the working area and can transfer the load not on a given axis, which leads to the “firing” of the jack from under the lifted load);

- contamination of the working fluid (oil contains particles of debris or metal wear, which adversely affects the quality of the device).

Disassembly and diagnostics

Standard repair of a hydraulic jack does it yourself, with the identification of defective places in the device and preliminary preparation for servicing.

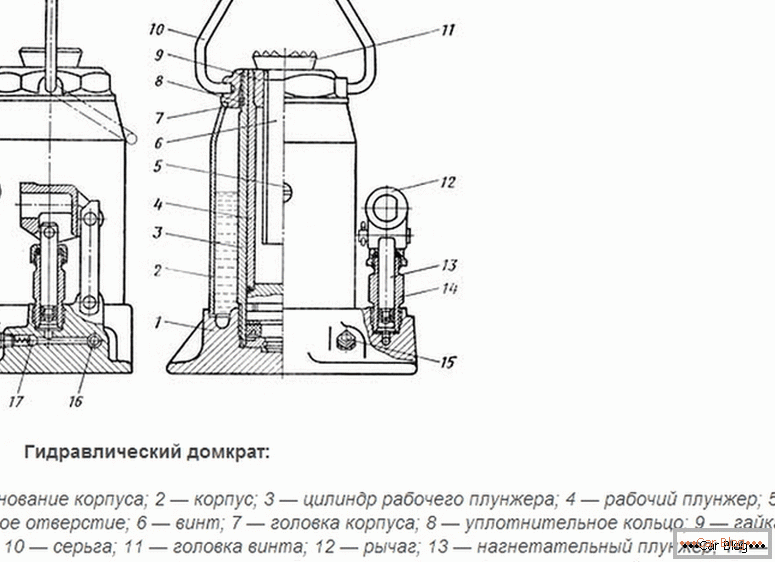

Types of hydraulic jacks

The work is carried out in several stages:

- Unscrew mounting hardware.

- The valve assembly is removed, providing pressure relief of the working fluid.

- We get the piston for inspection. The working side surface should be free of dents, notches, ditches and obvious signs of development. It has a smooth, even, polished surface. Otherwise, such roughness will cause poor performance of the jack.

- Next is a visual inspection of gaskets, seals, locking metal balls. If blocked channels are detected (a ball is ignited), then it will be removed with the help of loosening, it is advisable not to use metal hammers in order not to damage the sockets. Gaskets and seals if necessary, must be replaced.

- If the working hydraulic cavities are polluted, then flushing is carried out from the "grease" of contaminated surfaces. Small channels are allowed to be cleaned with copper wire. It is not desirable to do this operation with a steel bar or nail, as the surface is damaged, and scratches and notches are left.

- Then the device is assembled in the reverse order of disassembly. After that, clean oil is poured in and the jack is pumped. The oil should be in sufficient volume so that it is enough to fill the device’s tank completely.

Oil filling and pumping jack

The device of the hydraulic jack assumes that the main driving force in the apparatus is oil. It is precisely as a working fluid that pushes the rod and moves all the cars up. The oil level must not be lower than the established norm, otherwise it will simply not be enough in volume to fill the necessary cavities inside the jack and to fulfill its lifting functions.

Disassembled hydraulic jack

Before pouring fresh working fluid into the device, it is necessary to get rid of old used oil. To do this, you need to unscrew the plug from the oil tank. First you need to substitute the tank for the collection of "mining".

After waiting a couple of minutes, a flushing fluid is poured into the device. Its cost is about 180 rubles. Pumping through the hydraulic channels flushing, get rid of unnecessary air bubbles. When the flushing fluid begins to flow into the oil reservoir, this means that there is no air left in the system.

Pumping should be carried out in accordance with the recommendations of the manufacturer. They are usually listed in the instructions for use.

After draining the “rinse” into a special container, the liquid is passed around another 1-2 additional times.

So you can be confident in the result. After this pumping pumped out.

Then you can pour new oil. This operation is performed to the level specified by the manufacturer. The lack of working fluid can adversely affect the functioning of the jack. He simply will not gain the necessary power. Filling is carried out, as a rule, with a fully lowered working stem. Turning screw screw all the way to lower the jack as much as possible.

Schematic device of a hydraulic jack

The oil will gradually fill all working volumes. Therefore, it is necessary to wait several minutes until it is distributed throughout the system completely, and after that, if necessary, refill it to the working level. And so we add several times.

One of the signs that the required liquid level is set in the system is the absence of air bubbles on the surface of the oil during pumping.

See also: What is the difference between a diesel engine and a gasoline engine?Use and storage after repair

When the oil level in the tank is working, the jack is fully ready for use. It is only necessary to tightly close the lid of the tank. No other preparatory or additional procedures are required.

To use the device in the winter, it is desirable to use synthetic oils.

They often have better readings when working in the cold than mineral liquids. If it is necessary to use a jack at negative temperatures, then it is advisable not to use it for a long time, since the oil changes its properties at low temperatures. It increases viscosity and reduces frictional properties.

Store the jack is recommended with the vertical position of the rod.

This can avoid oil leaks. It is preferable to choose a storage place with a positive constant temperature in order to avoid condensation and rust on working surfaces.