Chains on car wheels - an attribute that is required in each vehicle for movement in severe weather and climatic conditions. Thanks to them, they manage to move not only along the snow surface, but also along sandy soil, loose yellow soil or even slush. The high price of the original chains to improve cross-country, forcing car owners to create chains on the wheels with their own hands.

The necessary components for this can be found without any problems at any outlet that sells fixing equipment. Snow chains are removable protection, which improves the car’s driving performance and performs the function of a “cargo hold”. They were not created for one type of car, so they are relevant for the following vehicles:

- cars;

- SUVs;

- trucks.

Each type of chain depends on the size of the wheel. For all-terrain vehicles and heavy vehicles, these attributes are complemented by auxiliary spikes, contributing to a better cross-country vehicle.

Content

- 1 Structure and the necessary types of this design

- 2 Wide selection

- 3 How to make chains on wheels with your own hands

- 3.1 Soft chains

- 3.2 Metal chains

- 4 Real Alternative

Structure and the necessary types of this design

The material for this design are:

- metal cable, the diameter of which must be at least 0.4 cm;

- different sized hooks;

- clamps with screw fitting;

- mechanical chain tensioner;

- small fasteners.

The principle of use includes the same order of placement of all links on the surface of the tire wheel. The rupture of the device and the loss of the ability to slip will occur if this condition is violated. One of the common models, tested by many experts, consists of external and internal parts, passing over the entire surface of the tire wheel.

Details vertically connected to each other "cargo". The job of creating a chain for wheels with their own hands is available even to beginners. There are three main circuit patterns:

- лесенка;

- rhombus;

- court.

Each model in the current configuration has positive and negative sides. The most accessible and quickest way to manufacture is the “ladder” technique.

After accurate measurements, it will be possible to know how many meters of the chain you need to create. However, it should be borne in mind that, on average, it will take about 14-15 meters to assemble a chain adaptation of a car. As a rule, the recommended materials are stainless steel materials that can withstand continuous loads and are able to resist friction on abrasive surfaces. But first it is necessary to figure out which, in principle, there are snow chains on the wheels.

Wide selection

Many variants of "factory" products are represented by various manufacturers. Today, soft and metal chains can be distinguished. Soft car security features include:

- plastic chains on the wheels;

- rubber products;

- polyurethane coupling.

Они могут различаться не только по материалу, но и по рисунку. Востребованными являются такие металлические и мягкие в равной степени. Металлические считаются самыми прочными и надежными в использовании. Можно применять как на легковом транспорте, так и на тяжелых грузовых машинах. Могут отличаться по рисунку. Soft chains производятся из пластика, резины и полиуретана. Принцип их действия состоит в специальных нашивках с шипами.

Plastic chains on the wheels are among the latest developed materials. They are not particularly distinguished by their durability and are used exclusively on a loose surface, often in snow.

Rubber snow chains cover cars. They are popular in urban mode auto.

Polyurethane chains are most in demand in the sale. According to its characteristics, it is considered better than rubber due to its characteristics:

- increased wear resistance;

- resistance to various chemical products;

- crack resistant;

- availability of good flexibility;

- good tensile properties (even at low ambient air temperatures).

Advantages of polyurethane products:

- possible speed of movement reaches 60-80 km / h;

- noiselessness and smooth running of the machine;

- the thickness of chain links is less than metal;

- minimal tread wear;

- having thorns from metal and plastic;

- possess excellent all-terrain vehicle on surfaces such as snow, mud and ice;

- can be installed on any rubber.

The disadvantages are reduced to such factors as:

- hardening of car tires in frosty weather, which makes installation difficult;

- not as durable as iron;

- more expensive than metal.

How to make chains on wheels with your own hands

In each case, use your method of manufacture. It is slightly different for metal products as well as for other materials.

Soft chains

The considerable price of goods serves as the main reason that the owner of his transport decided to make soft chains on his own. Consider one of the current techniques.

The anti-slip chains with their own hands are a reinforcing wire connecting plates that have the ability to stretch and cover the wheel in a circle. The device looks like this: on the inner and outer rim of the tire there are two axial ropes connected by rubber plates “cargo drawers”.

Stepwise production algorithm:

- We cut off four axial branches, approximately 83 links each. For the connection are used "cargo", hooks are installed on both their sides, for the following connections.

- All parts must be connected. The first connection is mounted on the sixth link, and all subsequent after ten links.

- Carabiners are attached to both ends of the rubber plates, and after the fourth transverse plate, a chain segment is attached to one of the axial branches. A tension structure is held to one edge of an existing segment with a clamp, a hook is fixed to the other edge, for further coupling.

Metal chains

Metal chains отличаются надежной прочностью и гарантируют предельную вездеходность. В критический момент можно обойтись способом, обмотав автошину канатом, но, естественно, не все имеют его в багажнике машины. И это грозит опасной аварией для системы торможения, так как нарушает принцип действие установки.

Consider how to make chains on the wheels of metal itself. This requires:

- metal chain;

- hooks;

- clamps with screw-in clutch;

- Angle Grinder;

- vice for fixing;

- chain tensioner.

Carefully examine the circuit, making sure there are no technological defects. Determine the size of the chain links, you can after specifying the size of the required tires. Experienced drivers suggest that the design be in contact with two plates at the point of intersection with the ground surface. This increases the traction force and strength of the entire auxiliary system.

Preparatory work on mounting the wheel with your own hands consists of the following steps:

- cutting axial structures;

- cutting vertical structures;

- fixing the vertical parts on the sixth carbine axial chain;

- installation using rings or hook further vertical plates every nine links;

- a longitudinal billet is installed in the center, we fasten the segment, it consists of six carbines and one tensioning device with a hook.

The whole process with a certain experience takes no more than 45 minutes. If an electric welding machine is available, you can completely refuse and not use connections with threads. However, this will affect the quality of the material and aesthetics.

Install the product on the wheels of the machine, you can only make sure of its reliability.

It should be noted that such an introduction to the design of the car is fraught with certain disadvantages:

- the mechanical load on the gear, steering rack and suspension is significantly increased; as a result of frequent intensive or unreasonable use of such accessories, the steering rack breaks down;

- rubber wear increases;

- reduced efficiency;

- strong noise is produced;

- limiting the speed of movement, which can not be higher than 50-60 km / h.

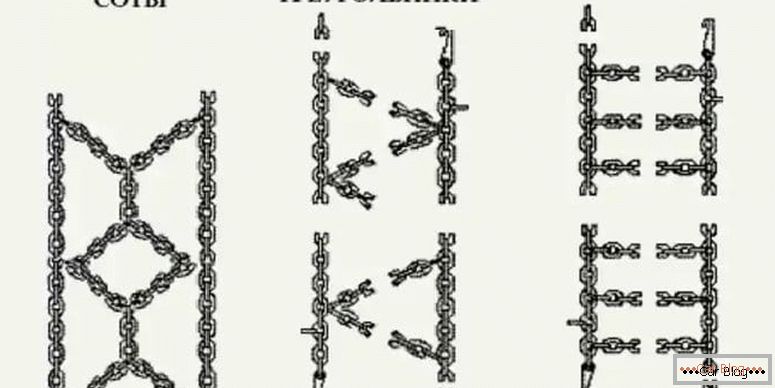

The type of contact between the surface of the chain is distinguished by the pattern:

- "Ladder" - the simplest type of chain. The simplest option in which the transverse plates are connected with two ropes in parallel.

- "Rhombus" - tying the chains is set according to the tire pattern, provides good durability and improves the quality of adhesion.

- "Honeycomb" - an intricate structure in which the ropes are connected diagonally, in the end we get a kind of interweaving.

When self-produced, anti-skid chains are fixed on the tire with such locking mechanisms:

- The S-shaped locking design is locked with a four-sided, or possibly hex key. But there were complaints about the lack of regulatory elements and the weak attachment. The installation of such a device is quite inconvenient.

- Hook lock design is widespread and in good demand. Putting the chain properly, you will not encounter problems. Fastening is carried out with a single screwdriver. Dismantling of the structure takes place without too much difficulty.

- Ratchet type locking mechanism is used on heavy vehicles. The main advantage of this mechanism is that it stands out for its durability and ease of use. It is mounted without auxiliary tools.

An incorrectly installed mechanism disrupts the sensors of the anti-lock brakes and fenders. On off-road vehicles, where the second bridge is connected, the mechanism is put on a constantly working pair of wheels. Installation work is performed by two methods:

- with jacking;

- on exactly standing car.

The first method using the jack is very simple. You fix the car at a height with a jack, reduce the pressure in the wheels to make it easier to do the work. Put on the chain and snap the locks.

Another thing, if the jack is not available, then you must do the following:

- you put chains in front of the car’s wheels, not allowing the links to twist;

- drive in a pair of wheels on a chain, before reaching the end of about 30-40 cm;

- put on the parking brake;

- throw the long side of the chain mechanism on the tire wheel so that the hook and clip are on the outside of the wheel;

- The last link axial spare parts and hook connect to the inside of the wheel;

- connect the carbine coupling to the tensioning system and fasten the knot;

- fix all vertical parts over the entire surface of the wheel, guide over the entire tire area and tighten.

For the same direction of the structural elements and to achieve maximum fit of all links, you need to drive about 50 meters by car.

Real alternative

In stores you can find anti-skid bracelets. But the savvy of domestic garage specialists is limitless. They were able to create copies of the original bracelets with their own hands. These are the same metal chains, only there are no transverse plates.

Dignity bracelets:

- unpretentious in manufacturing;

- easy to install;

- durable and efficient model.

Necessary parts to create:

- a detail of rubber with mounting the muffler VAZ;

- chain diameter not less than 0.5 cm

It only remains to cut the chains of the required length for tires.

Kits for assembling bracelets do-it-yourself is another option of a useful device for moving a car through problem areas. They set a reasonable price and at the same time they demonstrate good quality.

The set includes elements:

- threaded chain parts;

- fixing materials;

- Canada;

- vice.

It is important to always carefully read the assembly instructions from the manufacturer. It would be nice if you pre-train in warm weather or in garage conditions. You will gain experience that will further facilitate the installation of chains in the cold season.

It is important to know that the use of anti-slip chains is not permissible for driving on hard pavements such as asphalt or concrete. If you move on snow or loose ground, observe a speed of 15-20 km / h. It is strictly not allowed to slip, so do not sharply press on the accelerator.